Durable and Secure Welded Razor Wire Mesh: A Reliable Security Solution

By:Admin

In today's world, ensuring security and safety is paramount for both individuals and businesses. Whether it's a commercial property, a government facility, or a residential area, having proper perimeter security is crucial to prevent unauthorized access and potential threats. To address this need, companies like {} have introduced a revolutionary product - Welded Razor Wire Mesh, that offers an unparalleled level of security and protection.

With over 20 years of experience in the security industry, {} has established itself as a leading manufacturer of high-security fencing and perimeter protection solutions. The company's dedication to innovation and quality has made it a trusted name in the security sector, with a wide range of products that are designed to meet the diverse needs of their customers.

One of the key products in {}'s portfolio is the Welded Razor Wire Mesh, which has gained immense popularity for its effectiveness in deterring intruders and enhancing perimeter security. This innovative product is made from high-quality steel wire that is welded together to create a mesh pattern, with razor-sharp barbs or blades attached at regular intervals. The result is a formidable barrier that is virtually impossible to breach, providing a high level of security for any property.

The Welded Razor Wire Mesh is designed to be highly adaptable and can be installed on various types of fences, walls, and barriers, making it suitable for a wide range of applications. From industrial sites and military installations to prisons and correctional facilities, this product offers a robust and reliable solution for protecting perimeters and preventing unauthorized access.

One of the key advantages of the Welded Razor Wire Mesh is its versatility and customization options. {} offers a range of mesh sizes, barb lengths, and coatings to suit different security needs and environmental conditions. Whether it's a high-security prison that requires maximum deterrent effect or a residential property that needs a discreet yet effective barrier, the Welded Razor Wire Mesh can be tailored to meet specific requirements.

In addition to its unparalleled security features, the Welded Razor Wire Mesh is also designed to be long-lasting and low-maintenance. Constructed from durable and corrosion-resistant materials, this product is built to withstand harsh weather conditions and physical impact, ensuring that it continues to provide reliable security for years to come.

Moreover, {} prides itself on delivering not only high-quality products but also comprehensive support and service to its customers. The company's team of security experts works closely with clients to understand their specific security challenges and develop tailored solutions that meet their needs. From initial consultation and product selection to installation and after-sales support, {} is committed to ensuring that its customers have a seamless and satisfactory experience.

As the demand for high-security solutions continues to grow, the Welded Razor Wire Mesh has become an indispensable choice for many organizations and individuals who prioritize safety and protection. With its proven effectiveness, customization options, and long-term reliability, this product has set a new standard for perimeter security and has earned the trust of countless customers.

In conclusion, {}'s Welded Razor Wire Mesh stands as a testament to the company's commitment to innovation, quality, and customer satisfaction. With its unmatched security features, versatility, and durability, this product has become the go-to solution for anyone looking to enhance their perimeter security. As the security landscape evolves, {} remains at the forefront, continuously pushing the boundaries to provide cutting-edge security solutions for the modern world.

Company News & Blog

Top Filters For Extruding Machine: Get the Best Results

Filters For Extruding Machine is a new and innovative product that is set to revolutionize the plastic manufacturing industry. The product, which has been developed by an industry-leading company, is designed to improve the efficiency and quality of extrusion processes, ultimately reducing production costs and waste.The Filters For Extruding Machine is a cutting-edge solution that has been carefully designed to address the common challenges faced in the extrusion process. The product uses advanced filtration technology to remove impurities and contaminants from the plastic material, ensuring that the final product is of the highest quality. This improved filtration process also reduces the likelihood of machine downtime and maintenance, ultimately increasing productivity and profitability for plastic manufacturers.One of the key features of Filters For Extruding Machine is its unique design, which allows for easy installation and maintenance. The product is compatible with a wide range of extrusion machines, making it a versatile and cost-effective solution for manufacturers. The company behind the product has also taken into consideration the need for sustainability in the industry, and as a result, the filters are designed to be long-lasting and environmentally friendly.In addition to its technical capabilities, Filters For Extruding Machine also comes with a comprehensive support and maintenance package. The company provides training and technical support to ensure that the product is used to its full potential. This commitment to customer service is a testament to the company's dedication to providing exceptional products and services to the plastic manufacturing industry.The company behind Filters For Extruding Machine has a long history of innovation and excellence in the industry. With a team of experienced engineers and industry experts, the company has earned a reputation for developing high-quality and reliable products. The development of Filters For Extruding Machine is a testament to the company's commitment to continuous improvement and meeting the evolving needs of its customers.Furthermore, the company has a strong focus on research and development, constantly seeking new ways to improve processes and products in the plastic manufacturing industry. This dedication to innovation has positioned the company as a leader in the industry, and Filters For Extruding Machine is just one example of the company's ability to develop solutions that drive efficiency and quality in manufacturing processes.The launch of Filters For Extruding Machine has been met with excitement and anticipation from the plastic manufacturing industry. Manufacturers are eager to adopt this new technology, knowing that it has the potential to significantly improve their operations and bottom line. With its advanced filtration technology, easy installation, and comprehensive support package, Filters For Extruding Machine is set to become an essential tool for plastic manufacturers around the world.In conclusion, Filters For Extruding Machine is a game-changing product that has the potential to transform the plastic manufacturing industry. With its advanced filtration technology, versatile design, and comprehensive support package, the product is poised to improve the efficiency and quality of extrusion processes, ultimately reducing production costs and waste. The company behind the product has a proven track record of innovation and excellence in the industry, and Filters For Extruding Machine is a testament to their commitment to providing exceptional products and services to their customers. As the industry continues to evolve, it is clear that Filters For Extruding Machine will play a pivotal role in driving the success and sustainability of plastic manufacturing processes.

Durable and Flexible Mesh Screen for Plastic Materials

Introducing the Latest Innovation in Plastic Mesh Screen TechnologyIn the world of manufacturing and industrial production, finding the right materials and tools to create high-quality products is essential. One such crucial tool in the plastic industry is the mesh screen, which plays a vital role in various processes such as sorting, filtering, and sieving. This is why the introduction of the latest innovation in plastic mesh screen technology by (need remove brand name) has grabbed the attention of professionals and industry experts.(need remove brand name) is a renowned leader in the field of plastic manufacturing, known for its commitment to innovation, quality, and customer satisfaction. With a strong focus on research and development, the company has consistently pushed the boundaries of what is possible in the industry, and their latest product is no exception.The new plastic mesh screen by (need remove brand name) is a game-changer in the industry, boasting several key features that set it apart from traditional mesh screens. Made from high-quality, durable materials, the mesh screen is designed to withstand the rigors of industrial use, ensuring longevity and reliability. Its unique composition also makes it resistant to corrosion, abrasion, and extreme temperatures, making it suitable for a wide range of applications.One of the most significant advantages of the new plastic mesh screen is its superior filtering capabilities. The precision-engineered mesh design ensures efficient sieving and sorting, allowing for the separation of particles of varying sizes with unmatched accuracy. This feature is particularly valuable in industries such as food processing, pharmaceuticals, and mining, where the purity and quality of the end product are of utmost importance.In addition to its filtering capabilities, the new plastic mesh screen also offers enhanced flexibility and versatility. Its modular design allows for easy customization to fit specific requirements, making it suitable for a wide range of industrial applications. Whether it's used for separating different materials, protecting machinery from debris, or creating barriers for safety purposes, the mesh screen by (need remove brand name) offers a solution that is both effective and adaptable.Furthermore, the innovative design of the mesh screen also ensures improved airflow and ventilation, making it ideal for applications where consistent air circulation is necessary. This feature is particularly valuable in industries such as agriculture, construction, and HVAC, where maintaining optimal airflow is critical for the success of various processes.Another key highlight of the new plastic mesh screen is its environmental sustainability. Made from recyclable materials and designed to minimize waste, the mesh screen reflects (need remove brand name)'s commitment to reducing its environmental footprint and promoting eco-friendly practices in the industry. As the demand for sustainable solutions continues to grow, the company's emphasis on environmental responsibility is not only commendable but also aligns with the broader industry trends.In conclusion, the introduction of the new plastic mesh screen by (need remove brand name) marks a significant milestone in the industry, representing a leap forward in terms of innovation, performance, and sustainability. With its superior filtering capabilities, flexibility, and environmental consciousness, the mesh screen is poised to become a go-to solution for a wide range of industrial applications. As (need remove brand name) continues to lead the way in plastic manufacturing, their latest innovation reaffirms their position as a pioneer in the industry and sets a new standard for excellence.

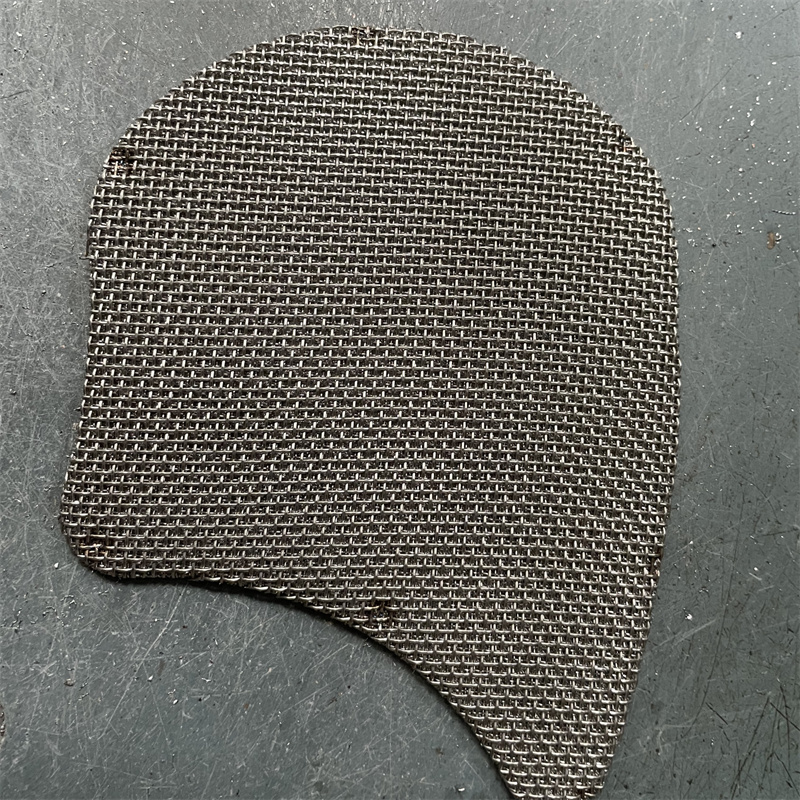

High-quality Nickel Wire Weave Mesh for Batteries: What You Need to Know

With the increasing demand for high-quality battery materials, {company name} has recently introduced a new product - Nickel Wire Weave Mesh For Battery. This innovative product is designed to meet the growing needs of the battery industry and is set to revolutionize the way batteries are manufactured.{company name} is a leading provider of advanced materials for a wide range of industries, including automotive, aerospace, and energy storage. The company has a strong track record of developing cutting-edge solutions that improve the performance and efficiency of various applications. With the introduction of Nickel Wire Weave Mesh For Battery, {company name} is reaffirming its commitment to innovation and sustainability.The Nickel Wire Weave Mesh For Battery is a high-performance material that offers numerous advantages for battery manufacturers. It is manufactured using advanced weaving techniques, resulting in a highly uniform and dense mesh structure. This unique design ensures excellent conductivity and mechanical strength, making it an ideal material for battery applications.One of the key benefits of Nickel Wire Weave Mesh For Battery is its exceptional corrosion resistance. This enables the material to withstand harsh operating conditions, including high temperatures and exposure to corrosive chemicals. As a result, batteries made using this mesh are more durable and have a longer service life, making them an attractive option for various applications, including electric vehicles and renewable energy storage systems.Furthermore, the Nickel Wire Weave Mesh For Battery offers excellent thermal stability, which is essential for maintaining consistent performance under extreme conditions. This is particularly important for high-power battery systems, where thermal management is critical to ensure safe and efficient operation. With this advanced material, battery manufacturers can enhance the thermal management of their products, leading to improved reliability and safety.In addition to its exceptional physical properties, the Nickel Wire Weave Mesh For Battery is also sustainable and environmentally friendly. {company name} is committed to reducing its environmental impact and has developed this material using eco-friendly production processes. As a result, battery manufacturers can rely on this mesh to meet their sustainability goals and contribute to a cleaner and greener future.The introduction of the Nickel Wire Weave Mesh For Battery demonstrates {company name}'s dedication to driving innovation in the battery industry. By providing a high-quality and sustainable material, the company is poised to support the growing demand for advanced battery solutions in a variety of applications. This innovative product is a testament to {company name}'s expertise in materials science and its ability to address the evolving needs of its customers.As the demand for high-performance battery materials continues to rise, {company name} is well-positioned to meet the needs of battery manufacturers worldwide. With its commitment to excellence and sustainability, the company is set to play a key role in shaping the future of battery technology and contributing to a more sustainable and efficient energy landscape. The Nickel Wire Weave Mesh For Battery is just one example of {company name}'s forward-thinking approach, and it is sure to make a significant impact in the battery industry.

Durable Stretching Mesh for Various Applications

[Company Name] is a leading manufacturer and supplier of industrial materials, including the innovative Nickel Stretching Mesh. The company has been dedicated to providing high-quality and reliable products to a wide range of industries for over 20 years. Their commitment to excellence has made them a trusted partner for businesses around the world.Nickel Stretching Mesh is one of the company's flagship products, and it has gained a reputation for its exceptional performance and durability. The mesh is made from high-quality nickel alloy, which allows it to withstand high temperatures and corrosive environments. It is widely used in various industrial applications, including filtration, sieving, and separation processes.The unique design of Nickel Stretching Mesh allows for a high level of flexibility and elasticity, making it ideal for applications that require a precise and uniform mesh size. It can be easily stretched to fit different shapes and sizes, making it a versatile solution for a wide range of industrial processes. Additionally, the mesh is resistant to wear and tear, ensuring a long service life and reducing the need for frequent replacements.One of the key advantages of Nickel Stretching Mesh is its ability to maintain a consistent mesh size, even under extreme conditions. This reliable performance is crucial for industries that rely on accurate filtration and separation processes to meet their production goals. The mesh can effectively capture and retain particles of various sizes, making it an essential component in many manufacturing and processing operations.In addition to its superior performance, Nickel Stretching Mesh is also easy to install and maintain, minimizing downtime and operational disruptions for businesses. The company provides comprehensive support and guidance to help customers integrate the mesh into their existing systems, ensuring seamless compatibility and optimal performance.The use of Nickel Stretching Mesh has been widely adopted in industries such as chemical processing, oil and gas, food and beverage, pharmaceuticals, and many others. Its versatility and reliability have made it a go-to solution for businesses seeking to optimize their production processes and improve overall efficiency.[Company Name] takes pride in its commitment to sustainability and environmental responsibility. The production of Nickel Stretching Mesh adheres to strict quality and environmental standards, ensuring minimal impact on the environment. The company also offers recycling and disposal solutions for used mesh, further demonstrating its dedication to sustainable practices.As a leader in the industrial materials industry, [Company Name] continues to invest in research and development to further enhance the performance and capabilities of Nickel Stretching Mesh. By staying at the forefront of technological advancements, the company aims to meet the evolving needs of its customers and address the challenges of modern industrial processes.In summary, Nickel Stretching Mesh from [Company Name] is a highly reliable and versatile solution for a wide range of industrial applications. Its exceptional performance, durability, and ease of use make it an essential component for businesses looking to optimize their production processes and achieve outstanding results. With a strong commitment to quality and sustainability, [Company Name] is a trusted partner for businesses seeking innovative and reliable industrial materials.

High-quality Galvanized Screen Wire for Sale: Durable and Long-lasting

Galvanized Screen Wire Offers Durable and Versatile Solution for Various Applications{} is a leading manufacturer and distributor of construction and industrial materials, serving a wide range of industries including construction, landscaping, and agriculture. The company is dedicated to providing high-quality products that meet the needs of its customers, and one of its standout offerings is its galvanized screen wire, which has gained popularity for its durability and versatility.Galvanized screen wire is a type of wire mesh that has been coated with a protective layer of zinc, giving it a strong resistance to rust and corrosion. This makes it an ideal material for outdoor applications, as it can withstand exposure to the elements without deteriorating. The galvanized coating also adds strength to the wire, making it a reliable choice for various structural and screening purposes.One of the key features of {}’s galvanized screen wire is its flexibility, which allows it to be easily shaped and cut to fit specific dimensions and requirements. This makes it a versatile solution for a wide range of applications, from creating protective enclosures for gardens and livestock to constructing barriers for industrial and construction sites.In addition to its flexibility, galvanized screen wire from {} is known for its excellent tensile strength and durability. This makes it a popular choice for fencing and screening applications, where it provides a secure and long-lasting barrier. Whether used for securing a perimeter or creating partitions within a space, the galvanized screen wire offers a reliable solution that can withstand wear and tear over time.Furthermore, {}’s galvanized screen wire is designed to meet industry standards for quality and performance. It undergoes rigorous testing and inspection to ensure that it meets the company’s strict quality control measures, providing customers with a product they can trust for their most demanding applications.The galvanized screen wire from {} is available in a variety of gauges and mesh sizes to accommodate different needs and preferences. This allows customers to select the right combination of wire thickness and opening size to suit their specific requirements, whether it’s for filtering debris, creating partitions, or securing a perimeter.The use of galvanized screen wire is not limited to just construction and industrial applications. With its strength, durability, and resistance to rust, it has also found its way into a variety of other uses, including agriculture, horticulture, and DIY projects. Whether used for building animal enclosures, crafting garden trellises, or making custom screens for windows and doors, the galvanized screen wire offers a reliable and cost-effective solution for a wide range of needs.With its strong focus on quality and customer satisfaction, {} has become a trusted source for galvanized screen wire and other industrial materials. The company’s commitment to providing high-quality products, backed by exceptional customer service and support, has made it a go-to supplier for businesses and individuals alike.As the demand for durable and versatile construction and industrial materials continues to grow, {} remains at the forefront, offering innovative solutions that meet the needs of its customers. The galvanized screen wire is just one example of the company’s dedication to providing reliable and high-quality products that offer long-term value and performance.In conclusion, {}’s galvanized screen wire stands as a testament to the company’s commitment to excellence. With its durability, versatility, and rigorous quality standards, the galvanized screen wire has become a staple in various industries, providing a reliable and cost-effective solution for a wide range of applications. As the company continues to innovate and expand its product offerings, it is poised to remain a trusted leader in the construction and industrial materials market.

High-Quality Filter Mesh: A Comprehensive Guide to Choosing the Right Mesh for Your Needs

Filter Mesh, a leading manufacturer of industrial filtration products, is revolutionizing the filtration industry with its advanced technology and commitment to excellence. With its extensive line of high-quality filter meshes, the company has become a trusted partner for businesses across various industries, including automotive, pharmaceutical, food and beverage, and many others. Filter Mesh's dedication to innovation and customer satisfaction sets it apart from other filtration companies, making it the go-to source for all filtration needs.The company's wide range of filter meshes is designed to meet the diverse needs of its customers. Whether it's for air, liquid, or solid filtration, Filter Mesh has a solution for every application. Its products are made from the highest quality materials to ensure maximum efficiency and durability. From stainless steel meshes to synthetic polymer meshes, Filter Mesh offers a comprehensive selection of options to suit any filtration requirement.One of Filter Mesh's standout products is its precision woven wire mesh. Engineered to provide precise filtration and excellent strength, these meshes are ideal for demanding applications such as aerospace, automotive, and oil and gas industries. The company's expertise in customizing mesh specifications allows for tailored solutions to meet specific filtration needs, making Filter Mesh a preferred choice for businesses seeking reliable and efficient filtration products.In addition to its product excellence, Filter Mesh places a strong emphasis on customer service and satisfaction. The company's team of experienced professionals works closely with customers to understand their filtration requirements and provide personalized recommendations. This commitment to understanding and addressing customer needs has earned Filter Mesh a stellar reputation for delivering exceptional products and service, contributing to its continued success in the filtration industry.Filter Mesh's dedication to quality and innovation is further demonstrated through its investment in research and development. The company continually explores new technologies and materials to enhance its product offerings and stay ahead of industry trends. By staying at the forefront of filtration innovation, Filter Mesh ensures that its customers have access to the latest advancements in filtration technology, enabling them to achieve optimal results in their operations.Moreover, Filter Mesh is committed to sustainability and environmental responsibility. The company recognizes the importance of minimizing its environmental impact and strives to develop eco-friendly filtration solutions. By using sustainable materials and manufacturing processes, Filter Mesh aims to contribute to a cleaner and greener future while delivering top-notch filtration products to its customers.As Filter Mesh continues to expand its reach and strengthen its position in the filtration market, the company remains focused on its core values of quality, innovation, and customer satisfaction. By delivering reliable filtration solutions and exceptional service, Filter Mesh has established itself as a trustworthy partner for businesses seeking top-of-the-line filtration products.With its unwavering dedication to excellence and customer-centric approach, Filter Mesh is poised to shape the future of the filtration industry and set new standards for quality and innovation. Businesses can rely on Filter Mesh to provide cutting-edge filtration products that deliver superior performance and reliability, making it the ultimate choice for all filtration needs.In conclusion, Filter Mesh's commitment to excellence, innovation, and customer satisfaction sets it apart as a leader in the filtration industry. With its comprehensive range of high-quality filter meshes, personalized customer service, and dedication to sustainability, Filter Mesh continues to be the go-to source for businesses seeking top-of-the-line filtration products. As the company continues to grow and innovate, it is well-positioned to shape the future of the filtration industry and set new benchmarks for quality and performance.

Spot Welded Screen Packs: Innovations in Screen Manufacturing

Spot Welded Screen Packs: Enhancing Efficiency and Quality in FiltrationIn today's fast-paced world, industries across various sectors rely heavily on efficient filtration systems to ensure optimum productivity and quality in their operations. One innovative solution that has gained significant attention and praise is the spot welded screen pack. Designed to enhance filtration performance, these screen packs have become an indispensable tool in many industries, contributing to enhanced efficiency and improved end products.{Company Introduction}Screen packs play a crucial role in filtration processes, acting as a barrier between the raw material and the desired end product. They consist of a series of wires that are woven or welded together to form a mesh structure. The size and configuration of the mesh can be tailored to meet specific filtration requirements, allowing for the separation of unwanted particles or impurities while allowing desired substances to pass through.Traditional screen packs often face challenges such as clogging and reduced efficiency over time, leading to frequent replacement and increased downtime. However, spot welded screen packs provide a highly effective solution, offering improved durability and longevity. By employing a spot welding technique, these screen packs eliminate the risk of unraveling or fraying, ensuring a more robust and long-lasting filtration system.One of the key advantages of spot welded screen packs is their enhanced structural integrity. The spot welding process involves joining the wires at specific points, creating a secure bond that prevents any movement or separation. This results in a seamless screen pack that can withstand higher levels of pressure and tension without compromising filtration efficiency. As a result, industries can significantly reduce maintenance costs and enhance overall operational performance.Moreover, the spot welding technique allows for greater customization and flexibility in the design of screen packs. Manufacturers can easily modify the mesh size, wire diameter, and open area percentage to suit the specific needs of each application. This adaptability ensures that the screen pack is precisely tailored to provide optimal filtration performance, eliminating any concerns of over-filtration or under-filtration.Spot welded screen packs are widely used in industries such as plastics extrusion, polymer processing, chemical manufacturing, food processing, and pharmaceuticals, among others. In plastics extrusion, for instance, these screen packs are employed in the melt filtration process to remove contaminants and impurities from the melted plastic before it is shaped into the desired form. The use of spot welded screen packs in this application ensures a cleaner and more consistent end product, minimizing defects and improving the overall quality.The pharmaceutical industry greatly benefits from spot welded screen packs as well. In the production of various medicines and drugs, it is vital to maintain strict quality control and ensure that no unwanted particles enter the final product. Spot welded screen packs offer an effective means of achieving this, providing a reliable filtration solution that meets high regulatory standards.As industries continue to push the boundaries of innovation and demand greater efficiency, the spot welded screen pack technology is expected to witness further advancements. Manufacturers are continually exploring new materials and innovative manufacturing processes to enhance the performance and durability of these screen packs. This will undoubtedly lead to improved filtration efficiency, reduced maintenance costs, and increased productivity, benefiting a wide range of industries.In conclusion, spot welded screen packs have revolutionized the filtration industry by offering enhanced durability, customization options, and improved filtration performance. Their unique design and manufacturing techniques have made them a highly sought-after solution for various industrial applications. As technology continues to evolve, spot welded screen packs are poised to play an even more significant role in safeguarding operational productivity and ensuring the delivery of high-quality end products.

High-Quality Nickel Wire Mesh for Button Cell Applications

Nickel Wire Mesh for Button Cell: An Essential Component in Battery ProductionIn the fast-paced world of technology, the demand for reliable and long-lasting batteries has never been higher. From smartphones to electric vehicles, the need for high-performance batteries is driving innovation in the industry. One essential component in battery production is nickel wire mesh, a material that plays a crucial role in the manufacturing of button cell batteries.Button cell batteries, also known as coin cell batteries, are widely used in small, portable electronic devices such as watches, calculators, and medical devices. These batteries are also increasingly being used in IoT devices and wearable technology. Nickel wire mesh is a key component in the construction of button cell batteries due to its unique properties and high conductivity.When it comes to the production of button cell batteries, the quality and reliability of the materials used are paramount. This is where the importance of a trusted and reputable supplier comes into play. With a commitment to excellence and a focus on innovation, [Company Name] has established itself as a leading manufacturer of nickel wire mesh for button cell batteries.[Company Name] specializes in the production of high-quality nickel wire mesh that meets the stringent requirements of battery manufacturers. With a state-of-the-art manufacturing facility and a team of experienced engineers and technicians, the company is able to produce nickel wire mesh with precise specifications and exceptional performance characteristics.The use of nickel wire mesh in button cell batteries offers several advantages. Firstly, nickel is a highly conductive material, allowing for efficient electron transfer within the battery. This is essential for ensuring the battery's ability to deliver a consistent and reliable power supply. Additionally, nickel wire mesh exhibits excellent corrosion resistance, ensuring the longevity and durability of the battery.In the production process, the nickel wire mesh is used as the current collector in the battery, providing a conductive surface for the flow of electrons. This critical role makes the quality of the nickel wire mesh a key factor in determining the overall performance and lifespan of the battery. With [Company Name]'s dedication to producing premium nickel wire mesh, battery manufacturers can have confidence in the reliability and efficiency of their products.Furthermore, [Company Name] is committed to sustainability and environmental responsibility in its manufacturing processes. The company employs eco-friendly practices and adheres to strict quality control measures to minimize its environmental impact. As the demand for batteries continues to rise, [Company Name] understands the importance of sustainable production methods to support a greener future.As the global market for electronic devices and battery-powered technologies continues to expand, the need for high-quality nickel wire mesh for button cell batteries will only grow. With [Company Name] leading the way in the production of this essential material, battery manufacturers can rely on a trusted partner for their nickel wire mesh needs.In conclusion, nickel wire mesh plays a vital role in the manufacturing of button cell batteries, powering a wide range of electronic devices and technologies. With [Company Name]'s expertise and dedication to excellence, battery manufacturers can access premium nickel wire mesh that meets their performance and sustainability goals. As the industry continues to evolve, [Company Name] remains at the forefront of innovation, driving the advancement of battery technology through its high-quality products and commitment to environmental stewardship.

Ultimate Guide: Exploring the Benefits and Uses of 4 Wire Mesh Fencing

Title: Durable and Versatile 4-Wire Mesh Fencing: A Secure Solution for Your Property Introduction:With a focus on providing high-quality fencing solutions, {Company Name} is proud to offer its latest product, 4-Wire Mesh Fencing, designed to meet the diverse needs of property owners. This innovative fencing option provides superior security, durability, and versatility, making it an ideal choice for residential, commercial, and agricultural applications. The follwoing news article will delve deeper into the features and benefits of 4-Wire Mesh Fencing, highlighting its potential impact on the fencing market. 1. Superior Security:In an era where security concerns are paramount, 4-Wire Mesh Fencing stands out as an effective solution to protect properties. Manufactured using advanced techniques and premium-quality materials, this fencing option ensures maximum security against trespassing, vandalism, and theft. Its tight interlocking pattern of horizontal and vertical wires greatly reduces the risk of breaching, making it an excellent choice for securing warehouses, schools, farms, and residential spaces alike. 2. Uncompromising Durability:Durability is a key factor for any fencing system, and 4-Wire Mesh Fencing excels in this aspect. Built to withstand harsh weather conditions, this fencing option is immune to rust and corrosion, thanks to its high-quality galvanized wire construction. Additionally, the wires are tightly woven to provide additional resistance against impacts, ensuring a long-lasting solution. This durability not only reduces maintenance costs but also guarantees peace of mind for property owners. 3. Optimum Versatility:The versatility of 4-Wire Mesh Fencing sets it apart from other conventional fencing options. Its flexible design allows for seamless installation on various terrains, including uneven or sloping land. Additionally, customization options such as different heights, wire thicknesses, and mesh sizes allow users to tailor the fencing to meet their specific requirements. Whether used for containing livestock, creating boundary partitions, or enhancing the aesthetic appeal of residential properties, this fencing option serves a wide array of purposes with ease. 4. Easy Installation and Maintenance:Simplicity and convenience are at the core of 4-Wire Mesh Fencing's design. Installation is hassle-free, thanks to its lightweight structure and modular composition. The system can be easily assembled and adjusted to fit any dimensions required. Additionally, the low-maintenance nature of this fencing option is a significant advantage, as regular upkeep is minimal, saving both time and money for property owners in the long run. 5. Environmental Considerations:{Company Name} values sustainability and environmental responsibility, which are reflected in the manufacturing and materials used for 4-Wire Mesh Fencing. The galvanized wires undergo an eco-friendly treatment process, reducing the environmental impact while maintaining their longevity. Moreover, the recyclable nature of the fencing materials further supports the company's commitment to environmental preservation. Conclusion:With its impeccable safety features, durability, adaptability, ease of installation, and eco-conscious approach, 4-Wire Mesh Fencing from {Company Name} is poised to revolutionize the fencing industry. Its potential applications across residential, commercial, and agricultural sectors make it a versatile solution for properties of all kinds. Invest in 4-Wire Mesh Fencing to enjoy a secure, resilient, and visually appealing fence that can withstand the test of time.

Revolutionary Filter Mesh Innovation Unveiled: Experience Unmatched Quality and Performance

Title: Innovative Filter Mesh Enhances Air Quality and Promotes SustainabilityIntroduction:In today's world, as the issue of environmental pollution becomes a growing concern, companies across various industries are striving to introduce sustainable solutions. One such pioneering effort comes from a leading company that specializes in advanced filtration technologies. They have developed a cutting-edge Filter Mesh, a breakthrough product that combats air pollution and significantly improves indoor air quality. This revolutionary filtration solution has the potential to revolutionize multiple sectors, including residential, commercial, and industrial spaces.1. The Need for Advanced Air Filtration Technology:Air pollution has emerged as a major global issue, with detrimental effects on both human health and the environment. The World Health Organization estimates that approximately seven million premature deaths occur every year due to air pollution-related complications. Indoor air pollution, caused by a variety of factors including dust, pet dander, and volatile organic compounds (VOCs), also poses a significant risk to human health.To address these concerns, {} developed its innovative Filter Mesh, a next-generation filtration solution designed to capture microscopic particles and harmful air pollutants effectively. This breakthrough technology boasts advanced features that ensure maximum air purification, creating healthier and cleaner indoor environments.2. Features and Benefits of the Filter Mesh:The Filter Mesh comprises a highly efficient filter media that finds versatile applications in a wide range of environments. Its key features include:a. Enhanced Particle Removal: {}'s revolutionary Filter Mesh is engineered to capture minute particles as small as PM2.5, PM10, pollen, and dust mites, while maintaining excellent airflow.b. High Filtration Efficiency: The unique design of the Filter Mesh ensures exceptional filtration efficiency, trapping up to 99% of airborne pollutants, including bacteria and viruses.c. Extended Lifespan: The durable construction of the Filter Mesh allows for extended lifespan, reducing overall maintenance and replacement costs.d. Sustainable Solution: In addition to its primary function of delivering clean air, the Filter Mesh is also eco-friendly. The materials used in its manufacturing process are recyclable, aligning with the company's commitment to environmental sustainability.3. Versatile Applications:The applications for {}'s Filter Mesh span across various sectors, highlighting its versatility and adaptability:a. Residential Spaces: The Filter Mesh is designed to be used in residential HVAC systems and air purifiers. By effectively removing allergens and other pollutants, it ensures improved indoor air quality, promoting healthier living environments for families.b. Commercial and Office Spaces: With an increasing emphasis on employee well-being, commercial buildings and offices are benefiting from the integration of the Filter Mesh. Its high-performance filtration capability helps create a healthy workspace conducive to productivity and employee satisfaction.c. Industrial Use: In industries, clean air is pivotal for worker safety and product quality. The Filter Mesh finds application in manufacturing facilities, ensuring that harmful particulates and contaminants do not compromise the overall process efficiency.4. Future Potential:The Filter Mesh's unique capabilities and sustainable design position it as a significant player in the global air filtration market. {}'s dedication to continuous research and development ensures that the Filter Mesh keeps evolving to meet future challenges.The company's commitment to excellence and innovation has earned them recognition within the industry. Their pioneering work in developing the Filter Mesh has received accolades, with numerous awards acknowledging its positive impact both on public health and sustainability efforts.Conclusion:In a world facing the dual challenges of air pollution and environmental degradation, companies like {} are leading the charge in developing sustainable solutions. Their state-of-the-art Filter Mesh promises to revolutionize the air filtration industry, providing cleaner and healthier indoor environments for homes, offices, and industries. By combining advanced technology with a commitment to sustainability, {} sets the stage for a cleaner, safer, and more sustainable future.