Guide to Wire Mesh Type Filters: What You Need to Know

By:Admin

In the industrial world, filtration is a critical process that is used to separate solids and fluids from gases and liquids. Whether it's for water purification, oil and gas processing, or pharmaceutical production, having an efficient and effective filtration system is essential. That's where the innovative Wire Mesh Type Filter comes in, revolutionizing the industrial filtration process with its advanced technology and unmatched performance.

The Wire Mesh Type Filter, developed and manufactured by {}, is designed to provide superior filtration capabilities for a wide range of industrial applications. The company, {} has been a leading player in the filtration industry for over 20 years, specializing in the development and production of high-quality filtration systems that meet the stringent requirements of various industries.

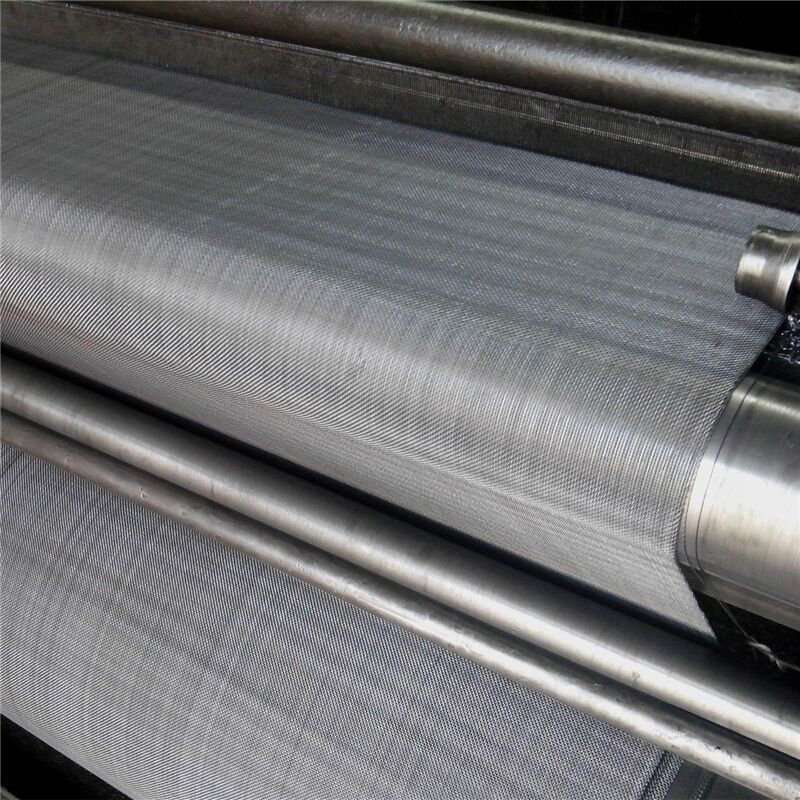

The Wire Mesh Type Filter stands out as a game-changer in the filtration sector due to its unique design and exceptional performance. It is constructed using high-quality stainless steel wire mesh, which is woven into a precise and uniform pattern to create a robust filtration element. This design allows the filter to effectively capture and retain particulate matter, ensuring that the output fluids or gases are free from any contaminants.

One of the key advantages of the Wire Mesh Type Filter is its high dirt-holding capacity, which allows for longer service life and reduced downtime for maintenance. This is especially beneficial for industries that rely on continuous production processes, as it minimizes the need for frequent filter replacements and maintenance, thereby increasing operational efficiency and cost savings.

Furthermore, the Wire Mesh Type Filter excels in providing consistent filtration performance, even under high-pressure and high-temperature operating conditions. Its durable construction and reliable filtration capabilities make it suitable for demanding industrial environments, where consistent and reliable filtration is crucial for product quality and process integrity.

The versatility of the Wire Mesh Type Filter is another important aspect that sets it apart from traditional filtration systems. It can be customized to meet specific application requirements, including different sizes, shapes, and micron ratings, making it suitable for a wide range of industrial processes. This versatility ensures that the filter can be seamlessly integrated into existing systems, providing a tailored filtration solution for various industrial needs.

In addition to its exceptional filtration performance, the Wire Mesh Type Filter is also designed with ease of maintenance in mind. Its simple and robust design allows for quick and hassle-free cleaning and replacement, minimizing downtime and maximizing operational uptime. This, coupled with its long service life, translates to significant cost savings and reduced overall operational expenses for industrial users.

Looking ahead, the future of industrial filtration is set to be transformed by the innovative technology and performance of the Wire Mesh Type Filter. With its superior capabilities and unmatched reliability, it is poised to address the evolving demands of industrial filtration and set new standards for efficiency and effectiveness in the filtration industry.

As {} continues to advance its expertise and capabilities in filtration technology, the Wire Mesh Type Filter stands as a testament to the company's commitment to delivering innovative and high-quality solutions for industrial filtration needs. With a track record of excellence and a passion for driving industry evolution, the company is well-positioned to lead the way in shaping the future of industrial filtration through its groundbreaking Wire Mesh Type Filter.

Company News & Blog

High-Quality Sintered Stainless Steel Filter for Effective Filtration

Sintered Stainless Steel Filter – The Ultimate Solution for Filtration NeedsIn today's industrial and commercial applications, filtration is a critical process that ensures the quality and efficiency of various processes. From liquids to gases, the need for reliable and effective filtration solutions has never been more important. That's where the Sintered Stainless Steel Filter from [company name] comes into play.[Company name] is a leading manufacturer and supplier of high-quality filtration products, including the renowned Sintered Stainless Steel Filter. With a strong commitment to innovation, quality, and customer satisfaction, the company has established itself as a trusted partner for businesses across a wide range of industries.The Sintered Stainless Steel Filter is a versatile and reliable filtration solution that offers a wide range of benefits for customers. It is designed to withstand high temperatures, corrosive environments, and high-pressure conditions, making it ideal for the most demanding applications. The filter is available in various sizes, shapes, and configurations, allowing for seamless integration into existing systems.One of the key advantages of the Sintered Stainless Steel Filter is its exceptional durability. Made from high-quality stainless steel, the filter is capable of withstanding harsh operating conditions without compromising its performance. This durability translates to long service life and reduced maintenance costs for users, ultimately leading to improved efficiency and cost savings.In addition to its durability, the Sintered Stainless Steel Filter offers superior filtration efficiency. Its sintered structure provides a high level of particle retention, ensuring that the filtered media remains free of contaminants and impurities. This is essential for applications where product purity is critical, such as in the pharmaceutical, food and beverage, and chemical industries.Furthermore, the Sintered Stainless Steel Filter is known for its versatility and adaptability. Whether it's used for liquid or gas filtration, the filter can be customized to meet specific application requirements. This flexibility makes it an ideal choice for a wide range of industries and applications, from petrochemical processing to environmental remediation.[Company name] takes great pride in its commitment to quality and customer satisfaction. The company's team of skilled engineers and technicians works closely with customers to develop custom filtration solutions that meet their unique needs. From initial design concept to final production, [company name] ensures that each Sintered Stainless Steel Filter is manufactured to the highest standards of quality and performance.The company's state-of-the-art manufacturing facilities are equipped with advanced production technologies and quality control processes, ensuring that every filter meets or exceeds industry standards. This dedication to excellence has earned [company name] a reputation for delivering reliable and high-performance filtration solutions that customers can trust.With its unmatched durability, superior efficiency, and versatile design, the Sintered Stainless Steel Filter from [company name] is the ultimate solution for all filtration needs. Whether it's for industrial processing, environmental protection, or product purification, this filter delivers exceptional performance and reliability, making it a valuable asset for businesses across diverse industries.In conclusion, the Sintered Stainless Steel Filter from [company name] is a testament to the company's commitment to innovation, quality, and customer satisfaction. With its exceptional durability, superior filtration efficiency, and versatile design, this filter stands out as the ultimate solution for all filtration needs. As businesses continue to seek reliable and high-performance filtration solutions, [company name] remains at the forefront, delivering cutting-edge products that set the standard for excellence in the industry.

Mesh Stretching Technique Expands Capabilities for Various Applications

Nickel Stretching Mesh, a revolutionary material in the field of industrial applications, is set to redefine the way metal mesh products are used in various industries. This cutting-edge material, developed and manufactured by a leading company in the field of metal mesh technology, has the potential to revolutionize a wide range of applications, from filtration and sieving to architectural and decorative uses.The company behind this groundbreaking material, with a history of innovation and excellence in the field of metal mesh technology, has been at the forefront of developing new and advanced materials for industrial and commercial use. With a team of experienced engineers and technicians, the company has consistently pushed the boundaries of what is possible with metal mesh, creating products that are not only durable and reliable, but also versatile and adaptable to a wide range of applications.Nickel Stretching Mesh, the latest addition to the company's line of innovative products, is a unique and highly flexible material that offers numerous advantages over traditional metal mesh products. Its unique structure, created using advanced manufacturing techniques, allows it to be stretched and molded into a wide variety of shapes and configurations, making it ideal for applications where traditional rigid mesh materials are not suitable.One of the key advantages of Nickel Stretching Mesh is its exceptional strength and durability. Unlike traditional metal mesh products, which can be prone to bending or warping under stress, this new material is designed to withstand high levels of pressure and tension without losing its shape or integrity. This makes it an ideal choice for applications that require a high degree of reliability and performance, such as industrial filtration and separation processes.In addition to its strength and durability, Nickel Stretching Mesh also offers superior corrosion resistance, making it an ideal choice for use in harsh and demanding environments. This makes it suitable for a wide range of industrial applications, from chemical processing and oil refining to marine and offshore operations, where exposure to corrosive substances and environments is a constant challenge.Another key advantage of this innovative material is its versatility. Thanks to its unique stretching and molding capabilities, Nickel Stretching Mesh can be used in a wide range of applications, from simple sieving and screening operations to complex architectural and decorative installations. This versatility opens up new possibilities for designers and engineers, allowing them to create innovative and unconventional solutions for a wide range of applications.The company behind Nickel Stretching Mesh is committed to providing its customers with the highest quality products and services. With a strong focus on research and development, the company continues to innovate and push the boundaries of what is possible with metal mesh technology, ensuring that its products remain at the forefront of the industry.As the demand for innovative and high-performance materials continues to grow, Nickel Stretching Mesh is set to become a key player in the field of industrial metal mesh products. With its exceptional strength, durability, and versatility, this revolutionary material is poised to redefine the way metal mesh products are used across a wide range of industries, setting new standards for performance and reliability. The company's commitment to excellence and innovation ensures that it will remain a leader in the field for years to come, providing its customers with cutting-edge solutions that meet their most demanding needs.

Durable and Versatile Epoxy Coated Wire Mesh for Various Applications

Epoxy Coated Wire Mesh: The Ultimate Solution for Durability and LongevityIn the world of construction and industrial applications, the choice of materials can make a significant impact on the overall quality and longevity of a project. One material that has been gaining popularity in recent years is epoxy coated wire mesh. This versatile and durable material is making waves in the industry, offering a wide range of benefits and applications for various projects. With its excellent anti-corrosion properties and long-lasting durability, epoxy coated wire mesh is becoming the go-to choice for many construction and industrial professionals.Epoxy coated wire mesh is a type of wire mesh that has been coated with a layer of epoxy, which is a thermosetting polymer. This coating provides the wire mesh with excellent resistance to corrosion, moisture, and other environmental factors, making it ideal for use in outdoor and high-moisture environments. The epoxy coating also adds an extra layer of protection to the wire mesh, making it more durable and long-lasting compared to traditional uncoated wire mesh.One of the leading companies in the production of epoxy coated wire mesh is {}. With years of experience in the industry, {} has established itself as a trusted provider of high-quality wire mesh products. The company is known for its commitment to excellence and innovation, constantly striving to improve its products and meet the evolving needs of its customers.The epoxy coated wire mesh produced by {} is designed to meet the highest standards of quality and performance. With a focus on durability and longevity, {}'s epoxy coated wire mesh is suitable for a wide range of applications, including concrete reinforcement, fencing, animal cages, and various industrial uses. The company offers a variety of wire mesh sizes and specifications to accommodate different project requirements, ensuring that customers can find the perfect solution for their specific needs.One of the key advantages of {}'s epoxy coated wire mesh is its excellent resistance to corrosion. Unlike uncoated wire mesh, which is prone to rust and deterioration over time, epoxy coated wire mesh retains its strength and integrity even in harsh environments. This makes it an ideal choice for outdoor applications, such as fencing and landscaping, where exposure to moisture and other environmental factors can lead to premature deterioration of materials.In addition to its anti-corrosion properties, epoxy coated wire mesh also offers superior durability and strength. The epoxy coating acts as a protective barrier for the wire mesh, preventing damage from impact, abrasion, and other mechanical stresses. This results in a longer service life for the wire mesh, reducing the need for frequent replacements and maintenance.Furthermore, {}'s epoxy coated wire mesh is easy to work with and install, making it a cost-effective solution for many construction and industrial projects. The wire mesh can be easily cut, bent, and shaped to fit specific requirements, allowing for greater flexibility and customization in various applications. This ease of handling, combined with its long-lasting durability, makes epoxy coated wire mesh a valuable investment for any project.With its impressive performance and versatility, epoxy coated wire mesh is quickly becoming the preferred choice for many construction and industrial professionals. Whether it's for concrete reinforcement, fencing, or other applications, the benefits of epoxy coated wire mesh are hard to ignore. And with companies like {} leading the way in producing high-quality epoxy coated wire mesh, the future looks bright for this innovative and durable material.

High-Quality Sintered Filters: A Guide to Understanding Their Benefits and Applications

Sintered Filters: The Key to Efficient Filtration SolutionsIn the world of industrial filtration, one name stands out: (company name). With a reputation for excellence and a commitment to innovation, they have become a trusted partner for businesses looking for top-of-the-line filtration solutions. From their state-of-the-art manufacturing facilities to their dedicated team of experts, (company name) is leading the way in the development and production of sintered filters.Sintered filters are a crucial component in many industrial processes, providing a highly efficient means of separating solids from liquids or gases. They are used in a wide range of applications, including oil and gas exploration, wastewater treatment, chemical processing, and more. The key to the effectiveness of sintered filters lies in their construction. They are made from fine metal powders that are compacted and then sintered at high temperatures to create a porous structure with precise filtration capabilities.At the heart of (company name)'s sintered filters is their dedication to quality and performance. They utilize the latest manufacturing technologies and employ a rigorous quality control process to ensure that every filter meets the highest standards. This commitment to excellence has earned them a reputation as a leading provider of sintered filters in the industry.One of the key advantages of (company name)'s sintered filters is their versatility. They offer a wide range of options in terms of materials, pore sizes, and configurations, allowing them to tailor their filters to meet the specific needs of each customer. Whether it's a high-temperature application, a corrosive environment, or a demanding filtration challenge, (company name) has the expertise and capabilities to deliver a custom solution.In addition to their standard sintered filter offerings, (company name) also provides engineering and design services to develop custom filtration solutions for unique and specialized applications. Their team of experienced engineers works closely with customers to understand their requirements and develop innovative solutions that meet their exact specifications.Furthermore, (company name) is committed to sustainability and environmental responsibility. Their sintered filters are designed to provide long-lasting performance, reducing the need for frequent replacements and minimizing the impact on the environment. Additionally, they are constantly exploring new materials and manufacturing processes to further enhance the sustainability of their products.As a testament to their expertise and dedication, (company name) has gained the trust of a wide range of industries, including aerospace, automotive, pharmaceutical, and more. Their sintered filters have proven to be reliable and efficient in even the most demanding applications, earning them a loyal customer base and a reputation as a go-to supplier for filtration solutions.Looking ahead, (company name) is committed to staying at the forefront of filtration technology. They continue to invest in research and development to further enhance the performance and capabilities of their sintered filters. By leveraging the latest advancements in materials and manufacturing processes, they aim to provide even more efficient and sustainable solutions for their customers.In conclusion, (company name) has established itself as a leader in the development and production of sintered filters, offering a comprehensive range of high-quality products and custom solutions for industrial filtration needs. With a proven track record of excellence and a relentless commitment to innovation, they are a trusted partner for businesses looking to optimize their filtration processes and achieve superior results. Whether it's a standard filtration requirement or a unique application, (company name) has the expertise and capabilities to deliver the perfect sintered filter solution.

Durable Fine Mesh Screen Filter for Effective Filtration

Leading Mesh Screen Filter Company Releases Innovative Fine Mesh Screen FilterAs the demand for high-quality filtration solutions continues to grow, [Company Name], a leading manufacturer of industrial filtration products, has announced the release of their latest innovation - the Fine Mesh Screen Filter. This new addition to their product line is designed to meet the needs of industries requiring precise particle separation and filtration.The Fine Mesh Screen Filter is specially engineered to provide superior performance in separating and removing fine particles from liquids and gases. With a mesh size ranging from 5 to 400 mesh, this filter is capable of capturing particles as small as a few microns, making it ideal for applications that require exceptional precision and efficiency.“We are excited to introduce our Fine Mesh Screen Filter to the market,” said [Company Name] spokesperson. “Our team has worked tirelessly to develop a filtration solution that addresses the increasingly stringent requirements of various industries. With its advanced design and unmatched performance, the Fine Mesh Screen Filter is poised to set a new standard in the field of particle separation and filtration.”In addition to its high-performance capabilities, the Fine Mesh Screen Filter is constructed using premium quality materials that ensure durability and longevity. The filter is available in a variety of materials, including stainless steel, brass, and titanium, providing customers with options to suit their specific operational requirements.The introduction of the Fine Mesh Screen Filter further solidifies [Company Name]’s position as an industry leader in the field of filtration technology. Since its establishment, the company has been at the forefront of developing innovative filtration solutions for a wide range of applications, including pharmaceutical, food and beverage, petrochemical, and water treatment, among others.[Company Name] has built a reputation for delivering high-quality products that meet the most demanding industry standards. With a commitment to continuous innovation and improvement, the company has consistently exceeded customer expectations and set new benchmarks for filtration efficiency and effectiveness.“We take great pride in our ability to understand the unique filtration challenges faced by our customers and provide them with tailored solutions that enhance their operational processes,” said the spokesperson. “The release of the Fine Mesh Screen Filter is a testament to our ongoing dedication to innovation and excellence, and we are confident that it will deliver exceptional value to our customers across various industries.”As the global focus on environmental sustainability and regulatory compliance intensifies, the need for advanced filtration solutions has become more critical than ever. The Fine Mesh Screen Filter is poised to address these evolving needs by offering a reliable and efficient means of separating and removing fine particles from various substances, contributing to enhanced product quality, operational efficiency, and environmental responsibility.[Company Name]’s commitment to excellence extends beyond product development, encompassing comprehensive customer support and service. The company’s team of experts is dedicated to assisting customers in finding the most suitable filtration solutions for their specific requirements, offering technical guidance, custom design and manufacturing, and ongoing maintenance and support.With the release of the Fine Mesh Screen Filter, [Company Name] continues to demonstrate its industry leadership and commitment to driving innovation in filtration technology. The company’s forward-looking approach and unwavering dedication to customer satisfaction position it as a trusted partner for businesses seeking reliable and high-performance filtration solutions.As industries seek to enhance their processes and meet evolving regulatory and environmental standards, the Fine Mesh Screen Filter is set to play a pivotal role in enabling them to achieve these objectives effectively and efficiently. With its exceptional filtration capabilities and durable construction, this innovative product is poised to make a significant impact across diverse industry sectors, helping businesses to streamline their operations and elevate their overall performance.

High-Quality and Durable 4x8 Metal Mesh Sheets: Perfect for Various Applications

article:Metal Mesh Sheets have become increasingly popular in construction and industrial projects due to their versatility, durability, and strength. Most commonly used in the construction of fences, gates, and cages, these mesh sheets are also utilized in filtration systems and architectural designs. One company that has made their mark in the industry with their high-quality 4x8 Metal Mesh Sheets is [company name], a leading manufacturer and distributor of industrial materials.With over [number] years of experience in the industry, [company name] has established a reputation for providing the highest quality products and exceptional customer service. Their 4x8 Metal Mesh Sheets, in particular, are a perfect example of the company's commitment to excellence. These sheets are made from high-quality steel wire that is woven together to create a sturdy and reliable mesh that can withstand even the toughest of conditions. The sheets are available in a variety of mesh sizes and wire thicknesses, making them suitable for a wide range of applications.One of the main advantages of [company name]'s 4x8 Metal Mesh Sheets is their durability. The sheets are resistant to corrosion, rust, and general wear and tear, making them ideal for use in outdoor applications. Additionally, the mesh has a high strength-to-weight ratio, which means that it is incredibly strong and able to hold up under pressure while remaining lightweight and easy to handle.Another advantage of these metal mesh sheets is their versatility. They can be easily cut, shaped, and welded to fit specific project requirements, making them suitable for a wide range of projects. Whether it's creating an ornamental gate or screening for a filtration system, the 4x8 Metal Mesh Sheets from [company name] can be customized to meet specific project needs.Furthermore, [company name] is committed to providing their customers with exceptional levels of service and support. From initial inquiry to post-purchase follow-up, their team of experts is always on hand to offer guidance and advice. Additionally, they offer fast and efficient shipping, ensuring that customers receive their orders on time and in perfect condition.In conclusion, [company name]'s 4x8 Metal Mesh Sheets are a top-quality product that exemplifies the company's commitment to excellence. With their durability, versatility, and exceptional customer service, it's no wonder that they have become a top choice for architects, engineers, and contractors for a wide range of industrial and construction projects. Whether you are looking for a high strength metal mesh sheet for a fencing project, or a specialized filtration system, [company name] has got you covered.

High-Quality 100 Mesh Stainless Steel Screen: A Must-Have for Various Applications

100 Mesh Stainless Steel Screen: A Durable and Reliable Solution for Filtering NeedsWhen it comes to industrial and commercial filtration needs, having the right equipment is crucial for the efficiency and effectiveness of the filtration process. One product that has been gaining attention in the industry is the 100 Mesh Stainless Steel Screen, which is a durable and reliable solution for various filtering needs.The 100 Mesh Stainless Steel Screen is designed to provide a high level of filtration accuracy and efficiency. It is made from high-quality stainless steel, which provides excellent resistance to corrosion and abrasion, making it suitable for a wide range of applications in industries such as chemical processing, food and beverage, pharmaceuticals, and many others.The 100 Mesh Stainless Steel Screen is capable of filtering out particles as small as 140 microns, making it ideal for applications where fine filtration is required. Its uniform mesh openings ensure a consistent and reliable filtration performance, making it an ideal choice for critical filtration processes.One of the key advantages of the 100 Mesh Stainless Steel Screen is its durability and longevity. Unlike other types of filters that may degrade over time, the stainless steel construction of this screen ensures that it can withstand harsh operating conditions and prolonged use without compromising its filtration performance. This not only reduces the frequency of replacement and maintenance but also helps minimize downtime and overall operating costs.In addition to its durability, the 100 Mesh Stainless Steel Screen also offers excellent flow rates, allowing for efficient filtration without impeding the flow of fluids or materials. This is particularly important in applications where a consistent flow is essential for the overall efficiency of the process.The 100 Mesh Stainless Steel Screen is also easy to clean and maintain, thanks to its smooth surface and non-reactive properties. This makes it an ideal choice for applications where hygiene and cleanliness are paramount, such as in the food and beverage industry.With its high level of precision and reliability, the 100 Mesh Stainless Steel Screen is a versatile solution for a wide range of filtration needs. Whether it's for separating solids from liquids, removing contaminants from gases, or any other filtration application, this screen delivers consistent and reliable performance, meeting the stringent requirements of various industries.As a company, we are proud to offer the 100 Mesh Stainless Steel Screen as part of our comprehensive range of filtration solutions. With a proven track record of providing high-quality products and exceptional customer support, we are committed to helping our customers find the best filtration solutions for their specific needs.With our extensive experience and expertise in the filtration industry, we are well-equipped to assist our customers in selecting the most suitable filtration products for their applications. Our team of experienced professionals is dedicated to providing personalized support and guidance, ensuring that our customers can make informed decisions and achieve optimal filtration efficiency.In conclusion, the 100 Mesh Stainless Steel Screen is a durable and reliable solution for a wide range of filtration needs. Its high level of precision, durability, and versatility make it a valuable asset for industries looking to enhance their filtration processes. As a leading provider of filtration solutions, we are committed to delivering exceptional products and support to help our customers achieve their filtration goals.

High-Quality Fine Mesh Filter for Effective Filtration - Available Now

Fine Mesh Filter, the leading provider of high-quality filtration solutions, is revolutionizing the industry with its innovative products and dedication to customer satisfaction. With a commitment to excellence and a focus on continuous improvement, Fine Mesh Filter has become a trusted partner for businesses in a wide range of industries.Specializing in fine mesh filtration products, Fine Mesh Filter offers a comprehensive selection of filters designed to meet the unique needs of each customer. Their filters are used in various applications including automotive, food and beverage, pharmaceutical, and many others. Whether it's for liquid filtration, air filtration, or gas filtration, Fine Mesh Filter provides efficient and reliable solutions that help businesses improve process efficiency and product quality.One of the key factors that sets Fine Mesh Filter apart from other filtration companies is their dedication to innovation. The company invests heavily in research and development to create cutting-edge filtration products that deliver superior performance and durability. Their team of engineers and scientists continuously explore new technologies and materials to stay ahead of market trends and ensure that their products meet the ever-evolving needs of their customers.In addition to their commitment to innovation, Fine Mesh Filter is also known for their exceptional customer service. Their team of filtration experts works closely with each customer to understand their specific requirements and provide tailored solutions that deliver optimal results. By offering personalized consultation and technical support, Fine Mesh Filter helps their customers maximize the efficiency and longevity of their filtration systems.Furthermore, Fine Mesh Filter emphasizes the importance of quality in every aspect of their operations. From the selection of raw materials to the manufacturing process, the company adheres to strict quality control measures to produce filters that meet the highest standards of reliability and performance. By maintaining a rigorous quality assurance process, Fine Mesh Filter ensures that their customers receive products that consistently exceed their expectations.As part of their ongoing commitment to sustainability, Fine Mesh Filter also strives to minimize their environmental impact. The company seeks to reduce waste and energy consumption in their manufacturing processes, and they actively explore eco-friendly materials and technologies to create filtration solutions that are both effective and environmentally responsible.Fine Mesh Filter's dedication to excellence and customer satisfaction has earned them a reputation as a trusted partner for businesses seeking high-quality filtration solutions. Their commitment to innovation, quality, and sustainability sets them apart in the industry, and their continued success is a testament to their unwavering dedication to exceeding customer expectations.With a steadfast focus on excellence and a passion for continuous improvement, Fine Mesh Filter is poised to remain at the forefront of the filtration industry for years to come. Their innovative products, exceptional customer service, and unwavering commitment to quality make them the ideal partner for businesses seeking reliable filtration solutions. As they continue to push the boundaries of filtration technology, Fine Mesh Filter will undoubtedly set new standards for excellence in the industry.

High-Quality Welded Mesh 50x50: Ideal for Various Industrial and Commercial Applications

In recent news, the demand for Welded Mesh 50x50 has seen a significant increase in the construction industry. This specific type of welded mesh is known for its durability, strength, and versatility, making it a popular choice for various construction and infrastructure projects. With its high-quality material and efficient design, Welded Mesh 50x50 has become a preferred option for engineers and contractors seeking reliable and cost-effective building solutions.The growing demand for Welded Mesh 50x50 can be attributed to its superior characteristics and performance. This type of welded mesh is manufactured using high-grade steel wires that are welded together to form a precise grid pattern. The 50x50 size refers to the dimensions of the grid, indicating the spacing between the intersecting wires. This specific size has proven to be ideal for a wide range of applications, including concrete reinforcement, fencing, industrial enclosures, and other structural support needs.One of the key advantages of Welded Mesh 50x50 is its exceptional strength and stability. The welded construction ensures that the wires remain firmly interconnected, providing a reliable support system for various construction projects. Additionally, the high-quality steel material used in the manufacturing process enhances the mesh's resistance to corrosion, rust, and other environmental factors, ensuring long-term durability and performance.Moreover, Welded Mesh 50x50 offers great flexibility in terms of customization and application. Its versatile nature allows for easy cutting, bending, and shaping to meet specific project requirements. Whether it's for concrete reinforcement in building foundations or for creating security barriers, this welded mesh can be seamlessly integrated into different construction scenarios. Its adaptability and ease of installation make it a popular choice among construction professionals looking for efficient and reliable building materials.In light of the increasing demand for Welded Mesh 50x50, it's crucial to highlight the role of a reputable manufacturer and supplier in meeting the industry's needs. {} is one such company that has established a strong reputation for producing high-quality welded mesh products. With a commitment to excellence and innovation, {} has been a leading provider of construction materials, including Welded Mesh 50x50, to various markets worldwide.The company prides itself on its state-of-the-art manufacturing facilities, equipped with advanced technology and machinery to ensure precision and consistency in every product. Through stringent quality control measures and rigorous testing procedures, {} delivers welded mesh products that meet international standards and specifications, guaranteeing reliability and performance in diverse construction applications.Furthermore, {} places a strong emphasis on customer satisfaction and service. With a dedicated team of professionals, the company offers comprehensive support and guidance to clients, helping them choose the right welded mesh products and solutions for their specific needs. {}'s commitment to building strong, long-lasting relationships with customers has made it a preferred partner for construction projects of all scales and complexities.In response to the rising demand for Welded Mesh 50x50, {} continues to invest in research and development, exploring new techniques and materials to enhance the performance and functionality of their products. By staying at the forefront of industry trends and advancements, the company is able to offer innovative solutions that address the evolving needs of the construction sector, ensuring that their welded mesh products remain a top choice for engineers and contractors.As the construction industry continues to grow and evolve, the demand for reliable and high-quality building materials like Welded Mesh 50x50 is expected to increase significantly. With a strong focus on quality, innovation, and customer service, {} is well-positioned to meet this demand and provide superior welded mesh products that contribute to the success and durability of construction projects around the world.

Durable and Reliable Stainless Steel Filter Mesh for Your Filtering Needs

Stainless steel has long been known for its durability and resistance to corrosion, making it an ideal material for a wide range of applications. One of the most common uses for stainless steel is in the production of filter mesh, which serves as a critical component in many industrial processes. Recently, a leading manufacturer of stainless steel filter mesh has made significant advancements in the development of their products, leading to improved performance and expanded applications.The company, with over 20 years of experience in the industry, has positioned itself as a key player in the global market for stainless steel filter mesh. Their dedication to quality, innovation, and customer satisfaction has earned them a reputation for excellence. With a state-of-the-art manufacturing facility and a team of highly skilled engineers and technicians, the company is able to produce a wide range of filter mesh products that meet the diverse needs of their clients.One of the company's latest advancements is the development of a new and improved stainless steel filter mesh that offers enhanced efficiency and durability. By utilizing advanced manufacturing techniques and high-quality materials, the company has been able to create a filter mesh product that outperforms the competition in terms of filtration accuracy and longevity. This breakthrough has opened up new possibilities for the use of stainless steel filter mesh in industries such as oil and gas, petrochemical, pharmaceutical, food and beverage, and many others.The new and improved stainless steel filter mesh offers a number of key benefits that set it apart from other options on the market. Its high tensile strength and resistance to corrosion make it suitable for use in even the harshest of environments. Additionally, the uniformity of the mesh structure ensures consistent performance and reliable filtration results. This level of quality and reliability is crucial for industries that rely on filtration processes to maintain efficiency and meet regulatory standards.Furthermore, the company has also expanded its range of stainless steel filter mesh to offer a variety of weave patterns and mesh sizes. This versatility allows clients to select the specific type of filter mesh that best suits their needs, whether it's for fine particle filtration or heavy-duty industrial applications. As a result, the company is able to cater to a wider range of industries and provide tailored solutions to meet their individual requirements.In addition to the technical improvements of their products, the company has also invested in streamlining their production processes to ensure quicker turnaround times and cost-effective solutions for their clients. This commitment to operational efficiency has positioned them as a reliable and competitive supplier in the global market for stainless steel filter mesh.Looking ahead, the company is focused on continued innovation and the development of new technologies to further enhance the performance of their stainless steel filter mesh. They are committed to staying at the forefront of the industry and providing their clients with cutting-edge solutions that deliver exceptional results.Through their dedication to quality, innovation, and customer satisfaction, this leading manufacturer of stainless steel filter mesh is setting new standards for the industry. With their new and improved products, expanded capabilities, and commitment to excellence, they are poised to make a significant impact in the global market for filter mesh solutions.