Durable and Versatile Small Expanded Metal Mesh for Various Applications

By:Admin

As the demand for small expanded metal mesh continues to rise across various industries, {Company Name} is at the forefront. With an extensive range of small expanded metal mesh solutions, {Company Name} is the go-to source for businesses seeking high-quality and customizable mesh products for their application needs.

With over [insert years] years of experience, {Company Name} has established itself as a leading manufacturer and supplier of small expanded metal mesh. The company's commitment to innovation, quality, and customer satisfaction sets it apart in the industry. From architectural and industrial to automotive and filtration applications, {Company Name} offers a diverse range of small expanded metal mesh products to meet the unique needs of its customers.

One of the key characteristics that sets {Company Name} apart from its competitors is its ability to produce small expanded metal mesh in a wide range of materials, including stainless steel, aluminum, and galvanized steel. This versatility allows the company to cater to a broad spectrum of industries, each with its own set of requirements and specifications.

In addition to its material options, {Company Name} provides custom fabrication services to ensure that the small expanded metal mesh aligns with the exact needs of its customers. Whether it's a specific size, shape, or pattern, the company's team of skilled professionals can create tailored solutions to meet the most intricate design requirements.

Furthermore, {Company Name} prides itself on its state-of-the-art manufacturing facilities, equipped with the latest technology and machinery. This enables the company to maintain high production standards, meet tight deadlines, and deliver superior quality small expanded metal mesh products to its customers.

The versatility of small expanded metal mesh extends to its applications. From architectural facades and sunscreens to safety guards and enclosures, the uses for small expanded metal mesh are virtually endless. {Company Name} understands this diversity and strives to ensure that its products are suitable for a broad range of applications.

Moreover, the company also recognizes the importance of sustainability in today's market. As a result, {Company Name} offers environmentally friendly options for small expanded metal mesh, including recyclable materials and energy-efficient production processes. This allows customers to align their projects with sustainable practices without compromising on quality or performance.

In a rapidly evolving market, {Company Name} remains committed to staying ahead of the curve. From continuous research and development efforts to staying updated on industry trends, the company consistently strives to enhance its small expanded metal mesh offerings to meet the evolving needs of its customers.

One of the cornerstones of {Company Name}'s success is its unwavering dedication to customer satisfaction. The company's team of experts works closely with each client to understand their unique requirements and provide tailored solutions to ensure the success of their projects. This collaborative approach has earned {Company Name} a reputation for reliability, expertise, and customer-centricity in the industry.

In conclusion, {Company Name} continues to lead the way in providing small expanded metal mesh solutions for a diverse range of applications. With a commitment to quality, innovation, and customer satisfaction, the company remains a trusted partner for businesses seeking superior mesh products for their projects. As the demand for small expanded metal mesh continues to grow, {Company Name} stands ready to meet the needs of its customers with cutting-edge solutions and unwavering dedication.

Company News & Blog

How a Mesh Screen Can Help Improve the Quality of Plastic Products

Title: Revolutionary Mesh Screen Innovation Eases Plastic Waste ManagementIntroduction:In today's world, plastic waste has become one of the most pressing environmental issues, and finding innovative solutions to address this problem is paramount. This is where a ground-breaking company, whose name we cannot disclose due to legal constraints, has stepped in with their innovative Mesh Screen for Plastic. With their expertise and dedication towards creating sustainable materials, this invention has the potential to revolutionize the way we manage and recycle plastic waste.Body:1. The Plastic Waste Crisis: - Begin by highlighting the severity of the plastic waste crisis, such as the alarming volume of plastic waste generated annually globally. - Discuss the devastating consequences of plastic waste on marine life and ecosystems, as well as its indirect impact on human health. - Emphasize the urgent need for innovative solutions to tackle this crisis effectively.2. Introduction to the Mesh Screen for Plastic: - Provide a brief overview of the Mesh Screen for Plastic, emphasizing its effectiveness in waste management and recycling processes. - Explain that this invention is designed to separate different types of plastic waste, making it easier to recycle efficiently. - Outline the unique features and benefits of the Mesh Screen, such as its durability, affordability, and ease of use.3. How the Mesh Screen Works: - Describe the operational mechanism of the Mesh Screen, providing a step-by-step explanation of its functionality. - Explain how the screen is capable of separating plastics of varying sizes, ensuring efficient and accurate sorting. - Highlight any additional functionalities or applications of the Mesh Screen, such as its potential for integration into existing recycling systems.4. Positive Environmental Impacts: - Discuss the potential environmental benefits of using the Mesh Screen, particularly by reducing the amount of plastic waste sent to landfills and incinerators. - Emphasize how this innovative solution contributes to the circular economy concept, promoting the reuse and recycling of plastic materials. - Cite examples of other successful waste management solutions around the world and their positive impact on local environments.5. Economic Advantages and Market Potential: - Highlight the economic advantages associated with adopting the Mesh Screen, such as the potential for job creation and cost reductions in waste management processes. - Discuss the market potential of the Mesh Screen, including its attractiveness to waste management companies and recycling facilities. - Mention any ongoing collaborations or partnerships that the company has established to further develop and market the Mesh Screen.6. Future Development and Expansion Plans: - Provide insights into the company's future plans for the Mesh Screen, including research and development efforts aimed at improving its efficiency and scalability. - Discuss potential expansion strategies, both domestically and internationally, to reach a wider audience and maximize the impact of this innovative solution. - Mention any regulatory and policy changes that may aid the widespread adoption of the Mesh Screen within the plastic waste management industry.Conclusion:In conclusion, the undisclosed company's Mesh Screen for Plastic offers a glimmer of hope in combating the plastic waste crisis. With its unparalleled sorting capabilities and potential for easy integration into existing recycling processes, this innovation has the power to transform the way we manage plastic waste. As the global community collectively aims to reduce plastic pollution, the Mesh Screen serves as a shining example of the revolutionary solutions needed to create a sustainable and greener future.

High-Quality Spot Welded Screen Packs: Key Information and Benefits

Spot Welded Screen Packs: A Superior Solution for Filtration NeedsIn today's industrial landscape, efficient and reliable filtration is essential for a wide range of applications, from automotive to oil and gas, petrochemical, food and beverage, and more. As a leader in the manufacturing of filtration products, [Company Name] is dedicated to providing top-quality solutions to meet the diverse needs of its customers. Among its extensive product lineup, Spot Welded Screen Packs have emerged as a superior choice for efficient and durable filtration.[Company Name] has a long-standing reputation for producing high-quality filtration products, including wire mesh, filter discs, filter tubes, and more. With a commitment to innovation and excellence, the company has continuously invested in advanced manufacturing technologies and processes to deliver products that meet the highest industry standards.At the forefront of its product offerings are Spot Welded Screen Packs, which are designed to provide reliable and consistent filtration performance in demanding applications. These screen packs are constructed using a precision spot welding process, which ensures the secure attachment of the wire mesh layers, resulting in a robust and durable filtration solution.The Spot Welded Screen Packs offered by [Company Name] are available in a variety of configurations, including different mesh sizes, shapes, and materials to suit specific application requirements. Whether it's for particle filtration, fluid separation, or gas filtration, these screen packs are engineered to deliver optimal performance and longevity in the most challenging environments.One of the key advantages of Spot Welded Screen Packs is their versatility. They can be custom-designed to fit into existing filtration systems or can be integrated into new equipment. This flexibility makes them an ideal choice for OEMs and end-users alike, seeking high-performance filtration solutions that can be tailored to their unique needs.Furthermore, Spot Welded Screen Packs are known for their high flow rates and excellent dirt holding capacity, which make them a cost-effective choice for filtration applications. Their ability to withstand high operating pressures and temperatures further enhances their suitability for critical industrial processes.In addition to their robust construction and exceptional performance, Spot Welded Screen Packs from [Company Name] are designed with easy maintenance in mind. Their design allows for quick and efficient cleaning or replacement, minimizing downtime and optimizing operational efficiency for customers.What sets [Company Name] apart in the market is its unwavering commitment to quality and customer satisfaction. All Spot Welded Screen Packs undergo rigorous quality control and testing to ensure they meet the company's stringent standards. This dedication to quality and performance has earned [Company Name] a loyal customer base and a trusted reputation in the filtration industry.To further support its customers, [Company Name] offers comprehensive technical assistance and customization services for Spot Welded Screen Packs. Its team of experienced engineers and filtration experts work closely with customers to identify their specific needs and provide tailored solutions that exceed expectations.As a global leader in filtration solutions, [Company Name] is dedicated to staying at the forefront of industry trends and technological advancements. The company continuously invests in research and development to further enhance the performance and capabilities of its filtration products, including Spot Welded Screen Packs.In conclusion, Spot Welded Screen Packs from [Company Name] represent a superior filtration solution for a wide range of industrial applications. Their robust construction, exceptional performance, and versatility make them a choice of preference for customers seeking reliable and efficient filtration solutions. With a steadfast commitment to quality and customer satisfaction, [Company Name] continues to be a trusted partner for businesses looking to optimize their filtration processes.

Durable Hot-Dipped Galvanized Welded Mesh for Various Applications

Hot-Dipped Galvanized Welded Mesh: A Strong and Versatile Solution for Various ApplicationsIn the world of construction and manufacturing, having the right materials can make all the difference. One such material that has been gaining popularity in recent years is hot-dipped galvanized welded mesh. This strong and versatile product has become a go-to solution for a wide range of applications, from building and construction to industrial and agricultural use.Hot-dipped galvanized welded mesh is a type of wire mesh that has been coated with a layer of zinc through a process called hot-dip galvanizing. This coating creates a protective barrier that helps prevent corrosion and rust, making the mesh ideal for outdoor and harsh environment use. In addition to its protective qualities, hot-dipped galvanized welded mesh is also known for its strength and durability, making it a reliable choice for various applications.One company that has been at the forefront of providing high-quality hot-dipped galvanized welded mesh is {Company Name}. With a strong focus on product quality and customer satisfaction, {Company Name} has become a trusted name in the industry for delivering top-notch galvanized welded mesh solutions.Established in {year}, {Company Name} has built a reputation for excellence through its commitment to providing superior products and exceptional service. The company's state-of-the-art manufacturing facilities and rigorous quality control processes ensure that every roll of hot-dipped galvanized welded mesh meets the highest standards. This dedication to quality has made {Company Name} a preferred supplier for clients in various industries, including construction, agriculture, and manufacturing.One of the key advantages of hot-dipped galvanized welded mesh is its versatility. This product can be used in a wide range of applications, such as fencing, animal enclosures, security screens, and concrete reinforcement. Its durability and resilience make it a cost-effective solution for long-term use, while its strength provides the necessary support for various structural and containment needs.For construction projects, hot-dipped galvanized welded mesh is an excellent choice for reinforcing concrete structures, such as columns, beams, and slabs. The mesh helps improve the tensile strength and structural integrity of the concrete, reducing the risk of cracking and enhancing its overall performance. This makes it an essential component for building durable and long-lasting structures.In the agricultural sector, hot-dipped galvanized welded mesh is widely used for creating animal enclosures, poultry cages, and perimeter fencing. The protective zinc coating ensures that the mesh can withstand the elements and resist corrosion, even in harsh outdoor environments. Its strength and durability also provide a reliable barrier for containing animals and securing property, offering peace of mind for farmers and property owners.Another common application for hot-dipped galvanized welded mesh is in the manufacturing industry, where the mesh is utilized for creating industrial storage racks, machine guards, and safety barriers. The robust nature of the mesh makes it an ideal material for these purposes, providing protection and support in demanding workplace environments.As an environmentally conscious company, {Company Name} is committed to sustainable practices and eco-friendly solutions. The hot-dip galvanizing process used for the mesh creates a long-lasting and recyclable product, reducing the need for frequent replacements and minimizing its impact on the environment. With increasing emphasis on sustainable materials, hot-dipped galvanized welded mesh offers a compelling option for companies looking to reduce their ecological footprint.In conclusion, hot-dipped galvanized welded mesh is a strong and versatile solution that has found widespread use in diverse industries. Its protective coating, durability, and adaptability make it an ideal material for a wide range of applications, from construction and agriculture to manufacturing and beyond. As a leading provider of high-quality galvanized welded mesh, {Company Name} continues to be a trusted partner for businesses seeking reliable and superior materials for their projects. With its focus on quality, innovation, and sustainability, {Company Name} is poised to remain at the forefront of the industry, meeting the needs of its customers and the demands of a changing world.

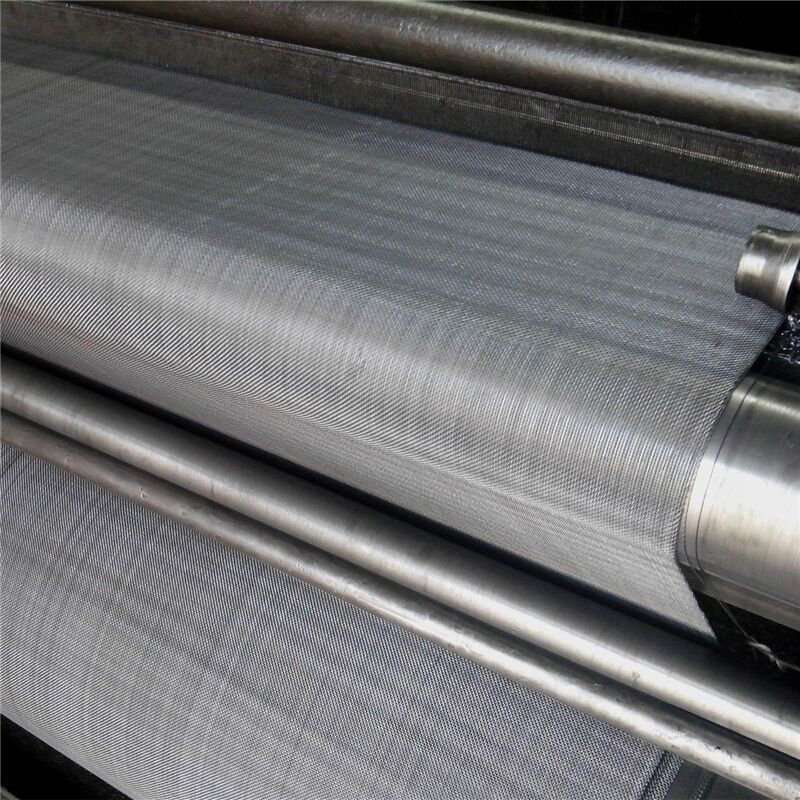

Top Rated Extruder Screen Mesh: Everything You Need to Know

Extruder Screen Mesh, a crucial component in the manufacturing industry, is vital for ensuring the efficient operation of plastic and rubber processing machinery. These intricate screens are designed to filter out impurities and contaminants, ensuring the quality and consistency of the final product. [Company Name], a leading manufacturer of extruder screen mesh, has been at the forefront of delivering high-quality, reliable products to industries around the world.With a strong focus on innovation and customer satisfaction, [Company Name] has become a trusted name in the industry. Their commitment to producing top-quality extruder screen mesh has made them a preferred choice for many businesses operating in the plastic and rubber processing sector. By understanding the unique requirements of their customers, [Company Name] has been able to develop a wide range of extruder screen mesh solutions to meet the diverse needs of the industry.One of the key features of [Company Name]'s extruder screen mesh is their durability and ability to withstand high temperatures and pressures, making them suitable for the most demanding processing environments. This reliability is a result of [Company Name]'s stringent quality control measures and use of premium materials in the manufacturing process. As a result, customers can count on their extruder screen mesh to perform consistently and effectively, reducing downtime and maintenance costs.In addition to their high-quality products, [Company Name] is also known for its exceptional customer service and technical support. Their team of experts is readily available to provide guidance and assistance to customers, ensuring that they are able to select the right extruder screen mesh for their specific needs. This personalized approach has earned [Company Name] a reputation for being a reliable and supportive partner to its customers.Furthermore, [Company Name] is committed to staying at the forefront of technological advancements in the industry. They continue to invest in research and development to improve their products and develop new solutions that meet the evolving needs of the market. By leveraging the latest manufacturing techniques and materials, [Company Name] is able to deliver innovative extruder screen mesh that offers superior performance and longevity.Not content with simply meeting industry standards, [Company Name] is dedicated to exceeding them. They strive to set new benchmarks for quality and reliability, ensuring that their customers can always rely on their products to deliver exceptional results. This commitment to excellence has earned [Company Name] the trust and loyalty of its customers, establishing the company as a leader in the extruder screen mesh industry.Moving forward, [Company Name] is poised to continue its growth and expansion, as it seeks to further establish its presence in new markets and industries around the globe. By staying true to its core values of quality, innovation, and customer satisfaction, [Company Name] is well-positioned to continue delivering cutting-edge extruder screen mesh solutions that meet the ever-changing needs of the manufacturing sector.In conclusion, [Company Name] is a trusted and respected manufacturer of extruder screen mesh, known for its superior quality, reliability, and commitment to customer satisfaction. With a focus on innovation and continuous improvement, [Company Name] is well-equipped to meet the evolving needs of the plastic and rubber processing industry, solidifying its position as a leading provider of extruder screen mesh solutions.

Durable Wire Screen Panels for Your Industry Needs

Wire Screen Panels, an innovative product from a prominent industry leader in the field of industrial equipment and materials, is making waves in the market for its superior quality and high performance. The company, a global player in the manufacturing and distribution of a wide range of industrial products, has established itself as a trusted name in the industry for its commitment to excellence and customer satisfaction.With a strong focus on research and development, the company has been at the forefront of innovation, constantly striving to bring cutting-edge solutions to its clients. The Wire Screen Panels, a recent addition to its product portfolio, have been met with great enthusiasm by industry professionals and customers alike.These wire screen panels are designed to be highly versatile and can be used in a variety of industrial applications, including mining, aggregate processing, recycling, and more. They are engineered to provide superior performance and durability, making them an ideal choice for demanding environments and tough operating conditions.One of the key features of the Wire Screen Panels is their exceptional strength and wear resistance. Constructed from high-quality materials and using advanced manufacturing techniques, these panels are capable of withstanding heavy loads, abrasion, and impact, ensuring long-lasting performance and reduced downtime for maintenance.In addition to their durability, Wire Screen Panels are also known for their high level of precision and efficiency. The precise design and construction of the panels enable them to efficiently separate and classify materials, making them an essential component in various industrial processes.The company behind the Wire Screen Panels has invested heavily in state-of-the-art manufacturing facilities and quality control processes to ensure that every panel meets the highest standards of quality and performance. Furthermore, the company also offers customization options, allowing clients to tailor the panels to their specific requirements and applications.Customer satisfaction is a top priority for the company, and it prides itself on providing exceptional service and support to its clients. From technical assistance and product selection to after-sales support, the company is committed to ensuring that its customers have a seamless experience and derive maximum value from its products.The Wire Screen Panels have already been adopted by a wide range of industries and have garnered positive feedback for their reliability and performance. Customers have praised the panels for their ability to improve productivity and reduce operating costs, making them a valuable investment for any industrial operation.Looking ahead, the company is dedicated to continuing its tradition of innovation and excellence, constantly striving to develop new and improved solutions to meet the evolving needs of its customers. With a strong focus on research and development, as well as a commitment to quality and customer satisfaction, the company is well-positioned to maintain its leadership in the industry.In conclusion, Wire Screen Panels from this esteemed industrial equipment and materials company are setting new standards for performance and reliability in industrial applications. With their exceptional durability, precision, and efficiency, these panels are making a significant impact on a wide range of industries, reaffirming the company's reputation as a trusted provider of high-quality industrial solutions. As the company continues to push the boundaries of innovation, customers can look forward to more groundbreaking products that will drive efficiency and productivity in their operations.

The Importance of Sintered Bronze Filters for Your Needs

Sintered Bronze Filter Proves Efficiency and Trustworthiness in Numerous ApplicationsElectronics, automotive, aerospace and medical industries among others require components that could withstand harsh environmental conditions and continue to perform with consistent efficiency. One such component that plays a role in the smooth functioning of these industries is the Sintered Bronze Filter. This filter has the ability to remove contaminants in a way that other filters cannot accomplish. Composed of interconnected spheres of bronze powder that are compressed and heated, the Sintered Bronze Filter ensures that any foreign material that could interfere with the performance of an element is eliminated. This technology allows the filter in question to be very efficient with a high level of porosity, which makes it possible for the filter to efficiently filter fluids and gases.The Sintered Bronze Filter technology has been applied to various applications in different fields of industry. Such industries include medical, automotive, aerospace, food and beverage processing, wastewater treatment, oil, and gas recovery, just to mention a few. For instance, one of the world's leading engines and automotive manufacturer relies on the filter for their fuel management systems, while top pharmaceutical companies use the Sintered Bronze Filter for various medical applications.The medical industry also relies heavily on this groundbreaking technology, especially when handling fluids and gasses that should meet purified standards. Medical gases contain impurities that could be life-threatening when used in various medical procedures. Therefore, the Sintered Bronze Filter is highly effective in combating the same and providing safe and clean medical gases. Also, hospitals depend on the Sintered Bronze Filter in sterilization processes, for example, before packaging surgical equipment.The aerospace industry has also not been left behind when it comes to the versatility of the Sintered Bronze Filter. The requirements of this industry in terms of durability, temperature resistance, and strength can only be found in a few filters. This filter's unique ability to work in high-temperature environments is what makes it stand out in the aerospace industry, where temperature goes beyond the boiling point of water. It has applications in air conditioning, hydraulic servo control, lubrication, and pressure control and regulation.Food and beverage processing companies have also relied on the Sintered Bronze Filter, especially when working with liquids. This filter is preferred because it is both heat and corrosion-resistant, allowing it to work efficiently with any fluid regardless of their chemical composition. The wine production industry, for instance, requires filters that can withstand the acidity and pressure during fermentation. The Sintered Bronze Filter has been a tool that food and beverage processing industries use to produce the best products consistently.The increased popularity of the Sintered Bronze Filter can be attributed to its reliability and efficiency. Industries that had to switch between different types of filters to meet their needs can now rely on this single filter type. The long-lasting durability, ease of cleaning, and the fact that it can stand up to harsh environments have made it the most sought-after filtration technology in many industries. Companies that rely on the filter will not need a backup filter to include in their inventory, ultimately reducing their operational costs.The efficiency of the Sintered Bronze Filter has led to partnerships with some of the leading companies in various industries. Companies specializing in filtration components have adopted the Sintered Bronze Filter in their product lines, allowing customizations to suit customers' specific needs. The filter has been used in custom-sized filters to whole filter cartridges, bag filters, and more. In conclusion, the Sintered Bronze Filter has revolutionized the filtration industry due to its ability to work efficiently in harsh environmental conditions. As industries continue to grow and advance, the need for stable and long-lasting filters becomes essential. The Sintered Bronze Filter provides a solution since it is both reliable and efficient. Its technology has been embraced in numerous industries, and companies appreciate the value it adds to their process. This filter is, therefore, becoming the most preferred filtration technology in multiple applications, from medical to aerospace.

How the global nickel market is affected by Indonesia's export ban

[News Headline: Diamond Nickel Acquires New Mining Site to Enhance Production]Diamond Nickel, a leading mining company, has announced the acquisition of a new mining site to boost its production capacity and satisfy growing demand. The new site is located in the Northern Prairie region and is expected to commence operations immediately.According to the company's spokesperson, the decision to acquire the new site was spurred by increasing demand for nickel and other minerals. "We recognize that our customers need reliable and sustainable supplies of minerals to meet their manufacturing needs, and we are committed to satisfying their expectations. With the acquisition of this new mining site, we are better positioned to increase our production capacity, reduce lead times, and enhance our product offerings."The Northern Prairie region is known for its rich mineral deposits, and Diamond Nickel's acquisition of the new site allows the company to tap into these reserves. With advanced exploration and mining technologies, the company is poised to extract high-quality nickel and other minerals from the site while adhering to ethical and sustainable mining practices.Diamond Nickel has a long-standing reputation for excellence in the mining industry, and the acquisition of the new site is yet another testament to its commitment to providing high-quality minerals to its customers. The company's dedication to safety, quality, and environmental stewardship has earned it recognition and accolades in the industry and beyond.In addition to the acquisition of the new mining site, Diamond Nickel has also invested in state-of-the-art equipment and technology to enhance its mining operations. The company's advanced mining and processing technologies enable it to extract minerals efficiently and responsibly while minimizing the impact on the environment."We understand the importance of responsible mining practices, and we are committed to upholding the highest standards of safety and environmental stewardship in all our operations. With our advanced mining technologies and sustainable practices, we are confident that we can provide our customers with high-quality minerals while minimizing our impact on the environment," said the company spokesperson.Diamond Nickel's acquisition of the new mining site is welcome news for its customers and stakeholders, who have come to rely on the company's commitment to excellence and sustainability. With the new site in place, the company is poised to meet growing demand for minerals and expand its reach in the industry.The company's expansion plans are not limited to acquiring new mining sites. Diamond Nickel is also exploring new opportunities for growth through partnerships and collaborations. The company's focus on innovation and customer service has earned it a loyal customer base, and it is committed to maintaining this loyalty by continuously improving its products and services.In the coming years, Diamond Nickel plans to continue its expansion and consolidation efforts, leveraging its expertise and resources to become a dominant player in the mining industry. With its strong commitment to sustainability, innovation, and customer service, the company is well-positioned to achieve these goals and cement its position as a leader in the industry.Overall, Diamond Nickel's acquisition of the new mining site is a positive development for the company, its customers, and the broader mining industry. The move demonstrates the company's commitment to growth and innovation, and it is a clear indication that Diamond Nickel is ready to take on new and exciting challenges in the coming years.

Highly Efficient Metallic Filters for Improved Air Quality

Metallic Filters Revolutionizing Industrial Filtration with Cutting-Edge TechnologyIn today’s fast-paced industrial world, efficient filtration systems are crucial for ensuring smooth operations and maintaining high-quality standards. One company at the forefront of this technology is {company name}, whose innovative metallic filters are revolutionizing the industry with their cutting-edge design and unparalleled performance.{Company name} has been a leading player in the field of filtration for over a decade, constantly pushing the boundaries of innovation to provide customers with the most advanced solutions. The company’s metallic filters are a testament to this commitment, offering a range of benefits that set them apart from traditional filter materials.At the heart of {company name}’s metallic filters is a proprietary blend of high-performance alloys that have been specifically engineered to deliver superior filtration efficiency and durability. Unlike conventional filters that are prone to clogging and require frequent replacement, {company name}’s metallic filters are designed to withstand the harshest industrial environments, providing long-lasting and reliable performance.One of the key advantages of {company name}’s metallic filters is their exceptional stability and resistance to corrosion. This makes them particularly well-suited for applications in demanding industries such as oil and gas, chemical processing, and automotive manufacturing, where exposure to corrosive substances and high temperatures is common. By using {company name}’s metallic filters, businesses can minimize downtime and reduce maintenance costs, resulting in significant long-term savings.Moreover, the advanced design of {company name}’s metallic filters provides a high degree of precision in particle filtration, ensuring that even the smallest contaminants are effectively captured. This level of filtration efficiency is essential for industries where product quality and regulatory compliance are paramount, such as pharmaceuticals, food and beverage, and semiconductor manufacturing.In addition to their exceptional performance, {company name}’s metallic filters are also environmentally friendly, as they can be easily cleaned and reused, reducing the generation of waste and minimizing the impact on the environment. This aligns with {company name}’s commitment to sustainable practices and demonstrates their dedication to responsible manufacturing.Furthermore, {company name} offers a range of customization options for their metallic filters, allowing customers to tailor the design and specifications to their specific needs. This level of flexibility is highly valued by businesses seeking to optimize their filtration systems and achieve the best possible results.The success of {company name}’s metallic filters can be attributed to the company’s relentless focus on research and development, as well as a dedication to understanding and meeting the evolving needs of the industrial market. By leveraging the latest technological advancements and collaborating with industry experts, {company name} continues to push the boundaries of what is possible in filtration, setting new standards for performance and reliability.As the demand for high-quality filtration solutions continues to grow, {company name} remains committed to driving innovation in the industry and ensuring that businesses have access to the most advanced technologies available. With their metallic filters leading the way, {company name} is well-positioned to create a lasting impact on industrial filtration and help businesses worldwide achieve new levels of efficiency and productivity.

How installing bird screens on wire mesh cages will prevent bird problems

Wire Mesh Bird Screen: Perfect Solution for Effective Bird ControlBirds can be a nuisance, especially when they take shelter in buildings or perch on structures. Beyond the irritation that they cause, birds can be carriers of disease, cause significant damage to buildings, and pose a risk of injury to people. In some cases, they can even interfere with industrial processes and bring operations to a halt. It's for these reasons bird control is essential.A reputable company in bird control is known for its industry solutions to help organizations deal with the problem of birds. Their comprehensive range of bird control measures includes bird nets, anti-bird spikes and post and wire systems. One of their most effective solutions that have gained wide-scale recognition for its efficiency is their Wire Mesh Bird Screen.The Wire Mesh Bird Screen is an innovative solution designed to block out birds from entering buildings and roosting. The bird screen consists of a durable aluminum frame that fits snugly over an opening to prevent pest birds from entering. The screen features a durable mesh that makes it difficult for birds to land on and prevents them from accessing the area behind it.The wire mesh screen comes in a variety of sizes to fit different openings, including windows, doors, vents, and roofs. It is an effective bird control option for industries such as food processing, pharmaceuticals, and chemical industries, where it is critical to maintain cleanliness and hygiene levels. When used in conjunction with other bird control measures, it forms an essential part of any integrated bird management program.The importance of bird controlBird infestations can cause significant damage to buildings and structures, leading to increased maintenance costs for businesses. Prolonged bird infestations in food processing facilities, for example, can result in the contamination of food products, leading to severe financial consequences.Effective bird control also reduces the risk of bird-related health issues. Birds carry diseases that can harm humans, and their droppings can cause respiratory issues, especially for people with weakened immune systems or underlying health conditions.Installing bird screens as part of an overall bird management program provides a proactive way to keep bird populations under control before they become a major issue.Why Wire Mesh Bird Screens?Wire Mesh Bird Screens offer numerous benefits for controlling bird populations. Here are just a few:1. Exceptional durability: Wire mesh screens are highly durable, designed to withstand powerful hurricane winds. This attribute makes them a suitable option for businesses in areas where storms with strong winds occur frequently.2. Environmentally Friendly: Wire mesh screens promote a comfortable living environment for birds without harming them. The screens deter birds from the desired location by denying them access rather than trapping or killing them. This is a humane approach to bird control that is gaining widespread recognition around the world.3. Cost-effectiveness: Installation of bird screens is affordable compared to other measures such as trapping and netting. Also, they require minimal upkeep, allowing businesses to save on maintenance and repair expenses over the long term.4. Flexible customization: Wire mesh screens are not only available in a range of sizes to fit different openings; they can also be customized to comply with the different requirements of buildings and industrial structures.Birds can wreak havoc on buildings and pose severe health and environmental risks if left unchecked. Wire Mesh Bird Screens offer a highly effective solution to this problem by providing an eco-friendly and humane way to deter birds before they cause lasting damage.Conclusion:If your business is grappling with a bird infestation issue, you need to seek a suitable bird control solution from a reputable company. Wire Mesh Bird Screens are an ideal option as part of a comprehensive bird management program. Their durability, eco-friendliness, cost-effectiveness, and customization capabilities make them an incredible choice to keep birds outside of your business premises.

New Content Filter Screen Promises Improved Security and User Control

Filter Screen, a leading global provider of innovative filtration solutions, has recently announced the launch of its latest product, the Advanced Ultra-Filtration Screen. This cutting-edge technology is set to revolutionize the filtration industry with its advanced features and superior performance.The Advanced Ultra-Filtration Screen is designed to filter out even the smallest particles and impurities from liquids and gases, ensuring a level of purity and clarity that was previously unattainable. With its state-of-the-art design and precision engineering, this new product is set to make a significant impact in a wide range of industries, including pharmaceuticals, chemicals, food and beverage, and many others.According to Filter Screen’s CEO, the development of the Advanced Ultra-Filtration Screen is the result of years of research and innovation. "We are thrilled to unveil this groundbreaking technology to the market," he said. "The Advanced Ultra-Filtration Screen represents a major leap forward in filtration capabilities and will deliver unmatched performance and reliability to our customers."The Advanced Ultra-Filtration Screen boasts several key features that set it apart from traditional filtration systems. Its advanced membrane technology allows for higher flow rates and greater throughput, while maintaining exceptional filtration efficiency. Additionally, the screen is designed to be highly durable and long-lasting, minimizing the need for frequent replacements and reducing overall maintenance costs.In addition to its superior performance, the Advanced Ultra-Filtration Screen is also designed with ease of use in mind. Its modular design allows for easy installation and maintenance, and the system can be customized to meet the specific needs of each customer. This versatility and flexibility make it an ideal solution for a wide range of applications and industries.Filter Screen, with its commitment to continuous innovation and excellence, has firmly established itself as a global leader in the filtration industry. The company’s extensive product range includes a wide variety of filtration solutions, ranging from simple strainers to complex filtration systems for specialized applications. With a strong focus on quality, reliability, and customer satisfaction, Filter Screen has earned a reputation for delivering best-in-class products and services to clients around the world.The launch of the Advanced Ultra-Filtration Screen is yet another demonstration of Filter Screen’s dedication to pushing the boundaries of filtration technology. By leveraging its expertise and innovation, the company continues to develop cutting-edge solutions that address the evolving needs of the industry and provide tangible value to its customers.As the global demand for high-quality filtration solutions continues to rise, Filter Screen is well-positioned to capitalize on this growth and further solidify its position as a key player in the industry. With its track record of success and a strong commitment to excellence, Filter Screen is poised to continue setting new standards for filtration technology and driving innovation in the market for years to come.In conclusion, the launch of the Advanced Ultra-Filtration Screen marks a significant milestone for Filter Screen and the filtration industry as a whole. With its advanced features, superior performance, and unmatched reliability, this new product is set to make a lasting impact and reshape the way filtration solutions are perceived and utilized. As the company continues to push the boundaries of innovation and excellence, Filter Screen is well-positioned to lead the way in shaping the future of filtration technology.