Durable Hot-Dipped Galvanized Welded Mesh for Various Applications

By:Admin

In the world of construction and manufacturing, having the right materials can make all the difference. One such material that has been gaining popularity in recent years is hot-dipped galvanized welded mesh. This strong and versatile product has become a go-to solution for a wide range of applications, from building and construction to industrial and agricultural use.

Hot-dipped galvanized welded mesh is a type of wire mesh that has been coated with a layer of zinc through a process called hot-dip galvanizing. This coating creates a protective barrier that helps prevent corrosion and rust, making the mesh ideal for outdoor and harsh environment use. In addition to its protective qualities, hot-dipped galvanized welded mesh is also known for its strength and durability, making it a reliable choice for various applications.

One company that has been at the forefront of providing high-quality hot-dipped galvanized welded mesh is {Company Name}. With a strong focus on product quality and customer satisfaction, {Company Name} has become a trusted name in the industry for delivering top-notch galvanized welded mesh solutions.

Established in {year}, {Company Name} has built a reputation for excellence through its commitment to providing superior products and exceptional service. The company's state-of-the-art manufacturing facilities and rigorous quality control processes ensure that every roll of hot-dipped galvanized welded mesh meets the highest standards. This dedication to quality has made {Company Name} a preferred supplier for clients in various industries, including construction, agriculture, and manufacturing.

One of the key advantages of hot-dipped galvanized welded mesh is its versatility. This product can be used in a wide range of applications, such as fencing, animal enclosures, security screens, and concrete reinforcement. Its durability and resilience make it a cost-effective solution for long-term use, while its strength provides the necessary support for various structural and containment needs.

For construction projects, hot-dipped galvanized welded mesh is an excellent choice for reinforcing concrete structures, such as columns, beams, and slabs. The mesh helps improve the tensile strength and structural integrity of the concrete, reducing the risk of cracking and enhancing its overall performance. This makes it an essential component for building durable and long-lasting structures.

In the agricultural sector, hot-dipped galvanized welded mesh is widely used for creating animal enclosures, poultry cages, and perimeter fencing. The protective zinc coating ensures that the mesh can withstand the elements and resist corrosion, even in harsh outdoor environments. Its strength and durability also provide a reliable barrier for containing animals and securing property, offering peace of mind for farmers and property owners.

Another common application for hot-dipped galvanized welded mesh is in the manufacturing industry, where the mesh is utilized for creating industrial storage racks, machine guards, and safety barriers. The robust nature of the mesh makes it an ideal material for these purposes, providing protection and support in demanding workplace environments.

As an environmentally conscious company, {Company Name} is committed to sustainable practices and eco-friendly solutions. The hot-dip galvanizing process used for the mesh creates a long-lasting and recyclable product, reducing the need for frequent replacements and minimizing its impact on the environment. With increasing emphasis on sustainable materials, hot-dipped galvanized welded mesh offers a compelling option for companies looking to reduce their ecological footprint.

In conclusion, hot-dipped galvanized welded mesh is a strong and versatile solution that has found widespread use in diverse industries. Its protective coating, durability, and adaptability make it an ideal material for a wide range of applications, from construction and agriculture to manufacturing and beyond. As a leading provider of high-quality galvanized welded mesh, {Company Name} continues to be a trusted partner for businesses seeking reliable and superior materials for their projects. With its focus on quality, innovation, and sustainability, {Company Name} is poised to remain at the forefront of the industry, meeting the needs of its customers and the demands of a changing world.

Company News & Blog

Top News: Stainless Steel Welded Wire Mesh Emerges as a Game-Changer in Industrial Applications

Stainless Steel Welded Wire Mesh Improves Durability and Versatility in Various IndustriesStainless steel welded wire mesh has become an essential component in numerous industrial applications. This innovative product provides enhanced durability, versatility, and reliability, making it a preferred choice across multiple industries. Its ability to resist corrosion and wear and tear makes it an ideal solution for various outdoor and indoor applications.({Company Name}), a leading manufacturer in the industry, offers a diverse range of stainless steel welded wire mesh to meet the needs of different sectors. With their commitment to quality and innovation, the company has established itself as a reliable provider of wire mesh solutions.Stainless steel welded wire mesh is manufactured by electrically welding the intersections of stainless steel wires, resulting in a sturdy and robust net-like structure. The strength and stability provided by this welded construction make it suitable for demanding applications such as filtration systems, security fencing, construction projects, agricultural applications, and many more.One of the key advantages of stainless steel welded wire mesh is its resistance to corrosion. The stainless steel material used in manufacturing is inherently resistant to rust and deterioration, making it suitable for use in harsh environments. Industries such as marine, oil and gas, and wastewater treatment rely on stainless steel welded wire mesh for its ability to withstand exposure to moisture, chemicals, and saltwater.In addition to its corrosion resistance, stainless steel welded wire mesh offers excellent strength and durability. The welded structure creates a rigid mesh that can withstand high pressures and heavy loads. This characteristic makes it an ideal choice for applications that require structural stability, such as reinforcement in concrete, transportation equipment, and safety barriers.The versatility of stainless steel welded wire mesh is another reason for its popularity among industries. The mesh can be manufactured in various mesh sizes, wire diameters, and patterns, allowing for customization to suit different requirements. It can be used for filtration purposes, providing precise and efficient separation of solids and fluids. Its use in acoustic panels and soundproofing applications highlights its versatility in noise reduction and control.Agricultural applications also benefit from the use of stainless steel welded wire mesh. The mesh can be used for animal enclosures, poultry cages, and garden fencing, ensuring safety and protection while allowing visibility and air circulation. Its resistance to animal bites and harsh weather conditions makes it an excellent long-term solution for farming and gardening.({Company Name}), with their extensive experience and industry expertise, offers a wide range of stainless steel welded wire mesh options. They provide tailored solutions to meet specific requirements, guaranteeing high-quality and durable products that deliver exceptional performance.The company's commitment to research and development ensures continuous improvement and innovation in their wire mesh solutions. They invest in state-of-the-art manufacturing techniques and advanced machinery to maintain the highest standards of quality and efficiency. Their dedicated team of experts works closely with customers to understand their unique needs and provide suitable recommendations accordingly.At ({Company Name}), their customer-centric approach extends beyond product quality. They offer comprehensive customer support, providing guidance from product selection to installation and maintenance. Their commitment to customer satisfaction sets them apart as a trusted partner in the industry.In conclusion, stainless steel welded wire mesh has become an indispensable component in numerous industries due to its durability, versatility, and resistance to corrosion. Its ability to withstand harsh environments, along with its strength, makes it suitable for a wide range of applications. ({Company Name}) is a leading manufacturer in the field, offering a diverse range of stainless steel welded wire mesh solutions to cater to the unique needs of different industries. With their commitment to quality and customer satisfaction, they continue to be a reliable choice for wire mesh solutions.

Discover the Promise of Decorative Expanded Metal Mesh

[Company Name] Introduces Innovative Decorative Expanded Metal Mesh for Various Applications[City, Date] – [Company Name], a leader in the metal fabrication industry, is proud to announce the launch of its latest product, a cutting-edge decorative expanded metal mesh. This highly versatile and aesthetically pleasing product is set to revolutionize the world of architectural and interior design.[Company Name] is renowned for its commitment to providing high-quality metal fabrication solutions. With an extensive portfolio of successful projects, the company has earned a solid reputation for its expertise and innovative approach. The introduction of this decorative expanded metal mesh is another testament to [Company Name]'s dedication to meeting the evolving needs of its customers.The new decorative expanded metal mesh is designed to add a touch of elegance and sophistication to any architectural or interior space. Made from high-quality materials, this mesh offers durability, strength, and superior craftsmanship, making it ideal for both decorative and functional applications. Whether it's used as cladding, room dividers, façade elements, or even in furniture design, the possibilities are endless.One key feature that sets this decorative expanded metal mesh apart is its intricate and visually appealing patterns. [Company Name]'s team of highly skilled designers has created a wide variety of innovative patterns to suit diverse tastes and design preferences. From traditional and classic motifs to modern and abstract designs, there is something to cater to every style.Moreover, [Company Name] understands that customization is essential in the world of design. As such, the decorative expanded metal mesh can be tailored to the specific requirements of each project. Whether it's adjusting the size, shape, or color of the mesh, [Company Name]'s skilled craftsmen can ensure that the final product perfectly fits the desired design vision.Architects, interior designers, and even homeowners will appreciate the many benefits of this new decorative expanded metal mesh. Apart from its aesthetic appeal, this product also offers functional advantages. Its open structure allows for excellent air circulation while providing shade and privacy, making it an excellent choice for outdoor spaces such as parks, gardens, and commercial plazas.In addition, the decorative expanded metal mesh can also be utilized for safety and security purposes. Its sturdy construction offers enhanced protection against break-ins, vandalism, and even natural disasters. Whether it's used as panels, screens, or enclosures, this mesh offers peace of mind without compromising on style.At [Company Name], quality and customer satisfaction are of utmost importance. The decorative expanded metal mesh undergoes a rigorous quality control process to ensure that it meets the highest industry standards. Furthermore, [Company Name] is committed to sustainability and uses eco-friendly materials and production methods whenever possible.To better serve its clients, [Company Name] provides comprehensive support and assistance throughout the entire project. From initial design consultations to installation guidance, the company's knowledgeable and experienced team ensures a smooth and hassle-free experience.With the introduction of this innovative decorative expanded metal mesh, [Company Name] aims to inspire creativity and elevate the possibilities in architectural and interior design. By combining functionality, durability, and striking aesthetics, this product has the potential to redefine the way metal meshes are used in a wide range of applications.For more information about [Company Name]'s decorative expanded metal mesh and to explore their extensive portfolio, please visit their website [URL].

Discover the Latest Tube Filter Mesh Innovations from China

Title: Chinese Tube Filter Mesh: A Breakthrough in Manufacturing High-Quality FiltersIntroduction:In recent news, China has made significant strides in the manufacturing industry with the development of a remarkable innovation – Tube Filter Mesh (name removed). This groundbreaking technology is reshaping the production of high-quality filters, revolutionizing numerous sectors worldwide. Through its unique manufacturing process, Tube Filter Mesh promises to deliver enhanced filtration efficiency, durability, and cost-effectiveness. Let's delve deeper into this remarkable invention and explore its potential implications.1. What is Tube Filter Mesh?Tube Filter Mesh is a state-of-the-art filtration system designed to improve the efficiency and effectiveness of diverse filtering applications. It is manufactured using advanced techniques that combine precision engineering, high-quality materials, and innovative design. With its exceptional attributes, Tube Filter Mesh has the potential to meet the growing global demand for reliable filtration solutions across various industries.2. Manufacturing Process:The production of Tube Filter Mesh involves a complex and meticulous manufacturing process, ensuring that the final product meets the highest industry standards. The process starts with the selection of premium-grade raw materials, such as stainless steel or other corrosion-resistant alloys, which provide the mesh with exceptional strength and durability.Next, these selected materials undergo a series of advanced precision cutting and welding techniques. These processes ensure that the mesh tubes are accurately formed, with consistent pore sizes, allowing for precise filtration. The use of automated machinery guarantees the highest level of uniformity throughout the manufacturing process.To further enhance the filtration capabilities, Tube Filter Mesh can be customized with various surface coatings to achieve specific functions. These coatings may include anti-corrosion layers, heat resistance, or even specialized coatings for specific industries, such as oil and gas or food processing.3. Advantages of Tube Filter Mesh:a. Enhanced Filtration Efficiency: The unique structure of Tube Filter Mesh allows for the maximization of filtration area and minimization of pressure drops during the filtration process. This results in improved filtration efficiency and reduced energy consumption.b. Increased Durability: The use of high-quality materials and precise manufacturing techniques ensures that Tube Filter Mesh boasts exceptional durability and longevity. Its resistance to corrosion, high temperatures, and mechanical stress makes it an ideal choice for challenging filtration applications.c. Customizability: Tube Filter Mesh can be tailored to meet specific filtration requirements, allowing for customization in terms of pore size, surface coatings, and dimensions. This flexibility enables the use of Tube Filter Mesh in a wide range of industries, including automotive, chemical, pharmaceutical, and water treatment.d. Cost-Effectiveness: The advanced manufacturing techniques used in the production of Tube Filter Mesh allow for efficient and cost-effective mass production. This, combined with its extended lifespan, reduces operating costs for businesses relying on filtration systems, making it a financially attractive option.4. Market Implications:The introduction of Tube Filter Mesh to the global market is expected to have far-reaching implications across various industries. Its superior filtration capabilities, extended lifespan, and cost-effectiveness position it as a crucial component for industries requiring efficient and reliable filtration solutions. This includes sectors such as wastewater treatment, oil and gas, food processing, and many more.Furthermore, as China continues to expand its presence in the global manufacturing industry, the development and export of Tube Filter Mesh will contribute to further strengthening the country's role as a technological leader and innovator.Conclusion:The emergence of the Tube Filter Mesh in China represents a significant breakthrough in the manufacturing of high-quality filters. Its exceptional filtration efficiency, durability, customizability, and cost-effectiveness make it a valuable asset for various industries worldwide. This remarkable technological advancement positions China at the forefront of innovation in the manufacturing sector, promising a brighter future for reliable and efficient filtration systems.

Guide to Using Galvanized Screen Wire for Your Projects

Galvanized Screen Wire Company Provides High-Quality Products for Diverse Applications{Company Name}, a leading provider of galvanized screen wire, has been offering high-quality products for a wide range of applications. With a commitment to excellence and customer satisfaction, they have established themselves as a trusted supplier in the industry.Galvanized screen wire is a type of wire mesh that has been coated with a layer of zinc to protect it from corrosion. It is commonly used in construction, agriculture, mining, and other industries for various purposes such as fencing, screening, and filtration. {Company Name} offers a variety of galvanized screen wire products to meet the diverse needs of their customers.One of the key factors that set {Company Name} apart from other suppliers is their attention to quality. The galvanized screen wire they offer is manufactured using high-quality materials and advanced production techniques to ensure durability and reliability. This allows their products to withstand harsh environmental conditions and heavy-duty applications, making them suitable for both indoor and outdoor use.In addition to their commitment to quality, {Company Name} also prides themselves on their wide range of product options. They offer galvanized screen wire in various sizes, mesh patterns, and wire gauges to accommodate different requirements. Whether customers need fine mesh for insect screening or heavy-duty wire for industrial fencing, {Company Name} has the right solution for their needs.Furthermore, {Company Name} provides personalized service and support to help customers find the most suitable galvanized screen wire for their specific applications. Their team of experts is available to assist with product selection, technical guidance, and customization to ensure that customers receive the best possible solution for their project requirements.Another advantage of choosing {Company Name} as a supplier is their commitment to sustainability. They strive to minimize their environmental impact by using eco-friendly materials and production methods, as well as implementing recycling and waste reduction measures. This aligns with the growing demand for environmentally responsible products and helps customers meet their sustainability goals.As a customer-centric company, {Company Name} values transparency and integrity in their business practices. They ensure fair pricing, timely delivery, and clear communication throughout the entire purchasing process to build trust and long-term relationships with their customers. This has contributed to their strong reputation and customer satisfaction in the industry.With a focus on continuous improvement and innovation, {Company Name} remains dedicated to enhancing their product range and services to meet evolving customer needs and industry trends. They regularly invest in research and development to introduce new advancements in galvanized screen wire technology, such as improved coatings, enhanced durability, and specialized applications.In conclusion, {Company Name} is a reliable source for high-quality galvanized screen wire that meets the diverse needs of customers across different industries. Their dedication to quality, extensive product range, personalized service, sustainability efforts, and customer-oriented approach make them a preferred supplier in the market. For anyone in need of galvanized screen wire solutions, {Company Name} stands out as a trusted partner for top-notch products and support.

Sintered Porous Stainless Steel Filters: A Comprehensive Overview

article.Sintered Porous Stainless Steel Filters: The Next Generation Solution for Filtration NeedsIn today's world, it is essential to maintain the quality of products and processes by effectively filtering different types of fluids and gases. However, it can be challenging to find a filtration solution that meets the require efficiencies, durability, and performance demands while also being cost-effective. This is where Sintered Porous Stainless Steel Filters come into play, offering a revolutionary solution for the filtration needs of various industries.The stainless steel filter manufacturer (need remove brand name) has been leading the industry for years, supplying its products to companies in different sectors globally. The Sintered Porous Stainless Steel Filters are among the newest additions to their product line, designed to provide a reliable and long-lasting solution for filtering different types of fluids and gases in many industries, including automotive, chemical, pharmaceutical, food and beverage, and many more.The filters are made of high-quality stainless steel that is sintered to create a porous structure. This porous structure is created by compressing tiny particles of stainless steel powder at high temperatures, resulting in a durable and robust filter material capable of handling a range of temperature conditions. The stainless steel powder used in these filters can range from 316L, 304L, and 310L grades, depending on the filtering requirements and environment conditions.The internal structure of the Sintered Porous Stainless Steel Filters features a uniform pore size distribution that allows for consistent and efficient filtration. With a pore size ranging from 0.1 to 100 microns, these filters can remove even the smallest of impurities, making them ideal for various applications. Additionally, the filters have a high surface area-to-volume ratio, providing a larger filtration area for enhanced efficiency and a more extended service life.The manufacturing process of the Sintered Porous Stainless Steel Filters also allows them to withstand significant changes in temperature, pressure, and corrosive environments without any significant wear and tear. This makes them an ideal solution for critical applications requiring high filtration quality standards. Additionally, these filters are capable of handling higher flow rates, providing faster filtration results than other conventional filters.Considering the increasing demand for clean and sterile environments in many industries, Sintered Porous Stainless Steel Filters are designed to meet the stringent filtration requirements. They can effectively remove bacteria, viruses, and other microscopic particles, ensuring clean and safe filtration in pharmaceutical, food and beverage, and medical industries.Furthermore, these filters are designed for ease of installation and maintenance, making them ideal for both small and large-scale filtration systems. They can be customized to meet specific filtration requirements, providing a wide range of applications across industries.In conclusion, the Sintered Porous Stainless Steel Filters are a revolutionary solution for filtration needs across industries. They provide consistent and efficient filtration, resist wear and tear even in harsh environments, and meet the stringent quality standards required in various applications. The stainless steel filter manufacturer (need remove brand name) is a reputable supplier of these filters and ensures that their clients receive quality products that are tailored to their needs.

Discover the Benefits of Plastic Mesh Screen in Various Applications

Plastic Mesh Screens: A Closer Look into an Innovative SolutionIn today's rapidly evolving world, technology continues to play a crucial role in addressing various challenges that we face. One such challenge is the protection of our environment, particularly when it comes to waste management. The use of plastic mesh screens has emerged as an innovative solution in this regard, revolutionizing industries and promoting a sustainable future.Plastic mesh screens, developed by a leading company in the industry, are a versatile product offering a wide range of applications. These screens are meticulously designed using high-quality materials, ensuring durability and reliability. Their lightweight and flexible nature make them easy to handle and install, while their sturdiness allows for long-term use.One of the primary applications of plastic mesh screens lies in waste management processes. Municipalities and waste management companies have increasingly turned to these screens to improve the efficiency of their operations. The screens are utilized in garbage processing plants, acting as a protective barrier to prevent small debris and waste from escaping into the environment during sorting and transportation. Such an application significantly reduces the risk of environmental pollution and enhances the overall effectiveness of waste management systems.Additionally, plastic mesh screens are widely used in the agriculture industry. They serve as an excellent solution for crop protection, safeguarding plants against pests, animals, and harsh weather conditions. The screens create a barrier that allows for the circulation of air, sunlight, and water, essential for the healthy growth of crops. Furthermore, they contribute to reducing the need for harmful chemical pesticides, thereby promoting environmentally friendly farming practices.Another industry where plastic mesh screens have gained prominence is construction. These screens find applications in reinforcing concrete structures, preventing cracks and enhancing the structural integrity of buildings. The flexibility of these screens allows them to be easily integrated into various construction processes, offering a cost-effective and sustainable alternative to traditional reinforcement methods.Moreover, plastic mesh screens have become an indispensable component in the manufacturing of air filters and ventilation systems. These screens effectively trap dust particles, pollen, and other airborne contaminants, improving air quality and promoting a healthier living environment. Their high durability ensures their longevity even in demanding environments, making them a reliable solution for filtration systems in residential, commercial, and industrial settings.The company behind the development and production of these plastic mesh screens has established itself as a reputable leader in the industry. With years of experience and a commitment to continuous innovation, the company has successfully delivered products that meet the highest quality standards.The company's production facilities boast state-of-the-art machinery, allowing for efficient manufacturing processes and quality control. Stringent testing procedures ensure that all plastic mesh screens meet rigorous performance criteria before they are made available to customers.Additionally, the company's commitment to sustainability extends beyond its product offerings. It actively pursues environmentally friendly practices throughout its operations, from sourcing eco-friendly materials to reducing waste and energy consumption. By doing so, the company aims to minimize its ecological footprint and contribute to the global efforts in preserving the environment.In conclusion, plastic mesh screens have emerged as an innovative solution to various challenges faced in waste management, agriculture, construction, and filtration industries. Their versatility, durability, and eco-friendly qualities make them an ideal choice for companies and individuals seeking sustainable alternatives. With the continuous efforts of companies like the one behind their development, plastic mesh screens are set to become a cornerstone of a greener and more efficient future.

Exploring the Importance of Tube Filter Mesh in China: A Comprehensive Overview

Title: China's Innovative Tube Filter Mesh Revolutionizing Industrial Filtration ProcessesIntroduction:China's manufacturing industry continues to lead the global market with innovative solutions and cutting-edge technologies. Among these groundbreaking inventions is the revolutionary Tube Filter Mesh, disrupting traditional industrial filtration processes. Developed by a prominent Chinese company, this mesh is poised to revolutionize various sectors by significantly enhancing efficiency, ensuring high-performance filtration, and reducing costs. This article delves into the intricacies of this remarkable invention, illustrating its potential impact and underscoring China's prowess in driving industrial innovation.1. Enhancing Filtration Efficiency:Traditional filtration processes often face challenges, such as clogging, low filtration rates, and the requirement for frequent maintenance. However, the Tube Filter Mesh, with its unique design and advanced materials, resolves these issues, ensuring excellent filtration efficiency. The mesh's tubular structure effectively prevents clogging by enabling a continuous flow while efficiently capturing impurities. This breakthrough technology enables smoother industrial operations, eliminating frequent downtimes caused by filter blockages.2. High-Performance Filtration:The Tube Filter Mesh's intricate construction is designed to achieve high-performance filtration across various industries. Engineered with precision, the mesh combines durability and flexibility to withstand demanding operating conditions. Its exceptional filtering capabilities guarantee the removal of even the tiniest particles, ensuring a superior final product in industries such as chemicals, pharmaceuticals, food processing, and automotive manufacturing. Manufacturers using this innovative mesh can expect increased product quality and customer satisfaction while meeting stringent regulatory standards.3. Sustainability and Cost Reduction:The Tube Filter Mesh significantly contributes to sustainable development as it eliminates the need for single-use filters, reducing solid waste generation. By replacing conventional disposable filters with this reusable mesh, companies can achieve substantial cost savings, lower resource consumption, and minimize their ecological footprint. Moreover, the mesh's long-lasting performance and low maintenance requirements significantly reduce operational costs, making it a highly cost-effective solution for industrial filtration needs.4. Wide Range of Applications:One of the key factors driving the rapid adoption of Tube Filter Mesh is its compatibility across a vast range of applications. From wastewater treatment to chemical processing, oil refining to pharmaceutical production, this adaptable mesh effectively fulfills diverse filtration requirements. Its versatility ensures versatile usage, making it a suitable choice for industries of varying scales and complexities.5. The Company's Dedication to Innovation:The development of Tube Filter Mesh exemplifies the Chinese company's commitment to innovation and addressing critical industry challenges. The company's extensive research, technological expertise, and dedication to continual improvement have resulted in this groundbreaking product. With a robust R&D team, state-of-the-art manufacturing facilities, and compliance with international quality standards, the company is poised to take the global industrial filtration market by storm.Conclusion:China's Tube Filter Mesh is a testament to the country's position as a global leader in industrial innovation. Its ability to enhance filtration efficiency, ensure high-performance, reduce costs, and find applications across diverse industries sets it apart from conventional filtration systems. As China continues to spearhead advancements in manufacturing technologies, the Tube Filter Mesh serves as a prime example of the country's dedication to driving sustainable, efficient, and cost-effective solutions for industries worldwide.

How a Mesh Screen Can Help Improve the Quality of Plastic Products

Title: Revolutionary Mesh Screen Innovation Eases Plastic Waste ManagementIntroduction:In today's world, plastic waste has become one of the most pressing environmental issues, and finding innovative solutions to address this problem is paramount. This is where a ground-breaking company, whose name we cannot disclose due to legal constraints, has stepped in with their innovative Mesh Screen for Plastic. With their expertise and dedication towards creating sustainable materials, this invention has the potential to revolutionize the way we manage and recycle plastic waste.Body:1. The Plastic Waste Crisis: - Begin by highlighting the severity of the plastic waste crisis, such as the alarming volume of plastic waste generated annually globally. - Discuss the devastating consequences of plastic waste on marine life and ecosystems, as well as its indirect impact on human health. - Emphasize the urgent need for innovative solutions to tackle this crisis effectively.2. Introduction to the Mesh Screen for Plastic: - Provide a brief overview of the Mesh Screen for Plastic, emphasizing its effectiveness in waste management and recycling processes. - Explain that this invention is designed to separate different types of plastic waste, making it easier to recycle efficiently. - Outline the unique features and benefits of the Mesh Screen, such as its durability, affordability, and ease of use.3. How the Mesh Screen Works: - Describe the operational mechanism of the Mesh Screen, providing a step-by-step explanation of its functionality. - Explain how the screen is capable of separating plastics of varying sizes, ensuring efficient and accurate sorting. - Highlight any additional functionalities or applications of the Mesh Screen, such as its potential for integration into existing recycling systems.4. Positive Environmental Impacts: - Discuss the potential environmental benefits of using the Mesh Screen, particularly by reducing the amount of plastic waste sent to landfills and incinerators. - Emphasize how this innovative solution contributes to the circular economy concept, promoting the reuse and recycling of plastic materials. - Cite examples of other successful waste management solutions around the world and their positive impact on local environments.5. Economic Advantages and Market Potential: - Highlight the economic advantages associated with adopting the Mesh Screen, such as the potential for job creation and cost reductions in waste management processes. - Discuss the market potential of the Mesh Screen, including its attractiveness to waste management companies and recycling facilities. - Mention any ongoing collaborations or partnerships that the company has established to further develop and market the Mesh Screen.6. Future Development and Expansion Plans: - Provide insights into the company's future plans for the Mesh Screen, including research and development efforts aimed at improving its efficiency and scalability. - Discuss potential expansion strategies, both domestically and internationally, to reach a wider audience and maximize the impact of this innovative solution. - Mention any regulatory and policy changes that may aid the widespread adoption of the Mesh Screen within the plastic waste management industry.Conclusion:In conclusion, the undisclosed company's Mesh Screen for Plastic offers a glimmer of hope in combating the plastic waste crisis. With its unparalleled sorting capabilities and potential for easy integration into existing recycling processes, this innovation has the power to transform the way we manage plastic waste. As the global community collectively aims to reduce plastic pollution, the Mesh Screen serves as a shining example of the revolutionary solutions needed to create a sustainable and greener future.

Welded Mesh: A strong and versatile option for a variety of applications

Title: Advancements in Mild Steel Welded Mesh Revolutionize Industrial ApplicationsIntroduction (98 words):In recent years, the industrial sector has experienced a significant shift towards utilizing advanced materials and innovative solutions to meet the evolving demands of modern manufacturing processes. One such groundbreaking development is the introduction of Mild Steel Welded Mesh, an exceptionally robust and versatile material. This article aims to explore the various applications and benefits of Mild Steel Welded Mesh, discussing its exceptional structural properties, durability, and increased cost-efficiency. As industries seek solutions that streamline production while ensuring safety and resilience, the introduction of this revolutionary mesh presents an exciting new chapter in industrial progress.1. Overview of Mild Steel Welded Mesh (119 words):Mild Steel Welded Mesh is a high-quality metal grid constructed using low-carbon mild steel wires, expertly welded together to form a strong and flexible mesh pattern. Made from mild steel, this type of mesh possesses superior strength and durability, making it an ideal choice for a wide range of industrial applications. Its innovate design provides structural reinforcement, excellent impenetrability, and reduced maintenance requirements. With its uniform grid pattern, Mild Steel Welded Mesh is also characterized by its enhanced load-bearing capacity and exceptional resistance to impact, corrosion, and extreme weather conditions. These attributes, alongside its affordability, render it a highly sought-after solution across various industries.2. Industrial Applications of Mild Steel Welded Mesh (209 words):2.1 Enhanced Safety and Security: Mild Steel Welded Mesh is widely employed in fencing systems, where it acts as a protective barrier for factories, warehouses, and other industrial premises. Its rigid construction deters trespassing attempts while maintaining visibility and providing adequate ventilation.2.2 Reinforced Construction and Concrete Slabs: Due to its remarkable strength, Mild Steel Welded Mesh is used in the construction industry to reinforce concrete slabs, walls, and columns, offering structural stability and increasing load-bearing capacity. This application finds particular utility in erecting commercial buildings, bridges, and tunnels.2.3 Advancements in Infrastructure: The implementation of Mild Steel Welded Mesh in the development of highways, railways, and flyover bridges has revolutionized infrastructure projects. Its corrosion-resistant properties ensure longevity and cost-effectiveness, making it an ideal choice for these large-scale construction projects.2.4 Automation and Robotics: The manufacturing industry relies heavily on Mild Steel Welded Mesh for the construction of customized industrial equipment, automation systems, and robotics components. The precise grid pattern facilitates the integration of mechanical parts, ensuring accuracy, durability, and optimal functionality.2.5 Environmental Applications: Mild Steel Welded Mesh is also used in ecological projects like land reclamation, coastal defense, and protection of vegetation against animals. Its strength and flexibility are instrumental in maintaining ecological balance, preventing erosion, and safeguarding sensitive habitats.3. Advantages and Benefits of Mild Steel Welded Mesh (177 words):The adoption of Mild Steel Welded Mesh offers several advantages over traditional materials, driving its growing popularity among various industries. Some key benefits include:3.1 Versatility: Mild Steel Welded Mesh boasts a versatile design that can be customized to meet specific requirements, allowing for a wide range of applications across diverse industries.3.2 Cost-Efficiency: Compared to alternatives, Mild Steel Welded Mesh presents a cost-effective solution by reducing material and labor costs, ultimately improving profitability.3.3 Durability and Longevity: Its exceptional structural properties provide outstanding durability and longevity, requiring minimal maintenance and replacement.3.4 Enhanced Safety: The welded construction of the mesh ensures high levels of safety by preventing collapses, safeguarding workers, and reducing the likelihood of unauthorized access.3.5 Eco-Friendly Solution: As an environmentally-friendly option, Mild Steel Welded Mesh is recyclable and sustainable, contributing positively to organizations' green initiatives.Conclusion (89 words):The emergence of Mild Steel Welded Mesh presents a game-changing advancement in the industrial sector, offering a host of benefits and applications that enhance safety, efficiency, and sustainability. This highly versatile material is poised to revolutionize various industries, from construction and manufacturing to infrastructure development and environmental restoration. As industries continue to push boundaries and seek innovative solutions, the adoption of Mild Steel Welded Mesh is set to become a standard practice, setting the stage for a more resilient, cost-effective, and environmentally-conscious future in industrial applications.

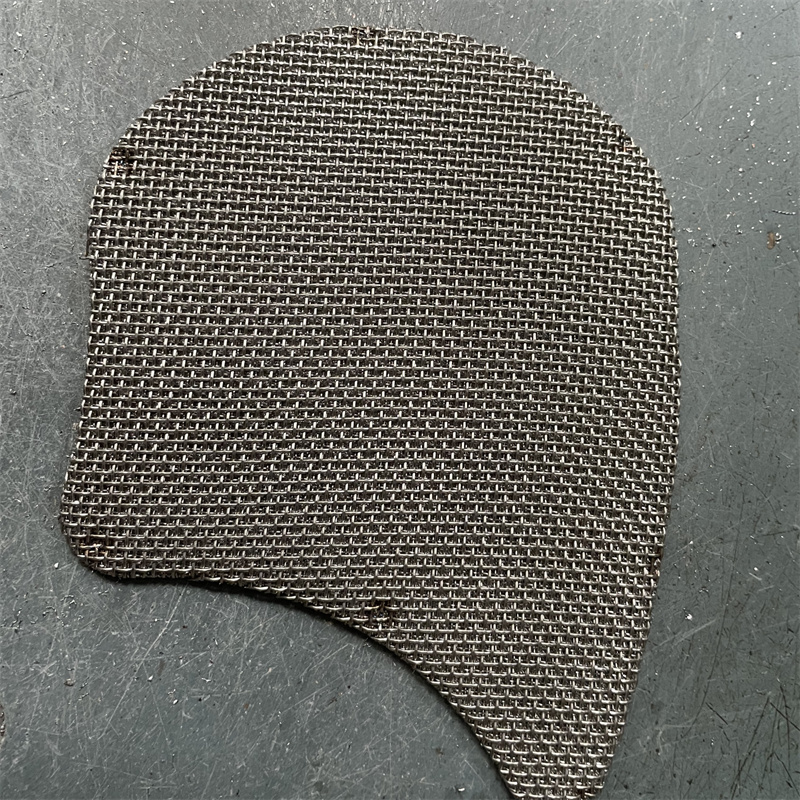

High-Quality Extruder Screen Pack for Industrial Applications

[Company Introduction]: ABC Manufacturing Company is a leading manufacturer of industrial filtration products, specializing in the production of extruder screen packs. With over 20 years of experience in the industry, ABC Manufacturing Company is known for its commitment to quality, innovation, and customer satisfaction. The company operates state-of-the-art manufacturing facilities and employs a team of highly skilled professionals dedicated to delivering top-notch filtration solutions to their global clientele. [News Content]:ABC Manufacturing Company, a renowned name in the industrial filtration industry, has recently unveiled its latest innovation in the form of an advanced extruder screen pack. This new product is set to revolutionize the filtration process in various industrial applications, setting a new benchmark for efficiency and performance.The extruder screen pack, designed and developed by ABC Manufacturing Company's team of engineers and researchers, is the result of extensive research and development efforts aimed at addressing the evolving needs of the industry. With a focus on enhancing filtration capabilities and streamlining production processes, the new extruder screen pack is poised to make a significant impact on the market.One of the key features of the new extruder screen pack is its superior durability and longevity. Constructed from high-quality materials, the screen pack is designed to withstand the rigors of high-pressure extrusion processes while maintaining its structural integrity over an extended lifespan. This durability not only translates to cost savings for businesses but also ensures uninterrupted production and minimal downtime.In addition to its robust construction, the extruder screen pack also boasts an innovative design that maximizes filtration efficiency. The precision-engineered mesh screen effectively captures impurities and contaminants, ensuring that the final product meets the highest quality standards. This level of filtration is crucial in industries such as polymer processing, plastic recycling, and food processing, where product purity is of utmost importance.Furthermore, the extruder screen pack from ABC Manufacturing Company offers versatility, with customizable options to suit specific application requirements. Whether it's the mesh size, screen diameter, or overall dimensions, the company provides tailored solutions to meet the unique needs of its customers. This flexibility underscores ABC Manufacturing Company's commitment to delivering personalized filtration solutions that align with industry demands.The introduction of the advanced extruder screen pack reflects ABC Manufacturing Company's dedication to innovation and technological advancement. By staying at the forefront of filtration technology, the company empowers its customers to enhance their operational efficiency and product quality. As a trusted partner to countless businesses across diverse sectors, ABC Manufacturing Company continues to raise the bar for excellence in the filtration industry.In conclusion, the unveiling of the new extruder screen pack from ABC Manufacturing Company marks a significant milestone in the realm of industrial filtration. With its cutting-edge features, unmatched durability, and customizable options, the screen pack is poised to reshape the landscape of filtration solutions. As the company continues to drive innovation and set new standards, it remains a force to be reckoned with in the global filtration market.