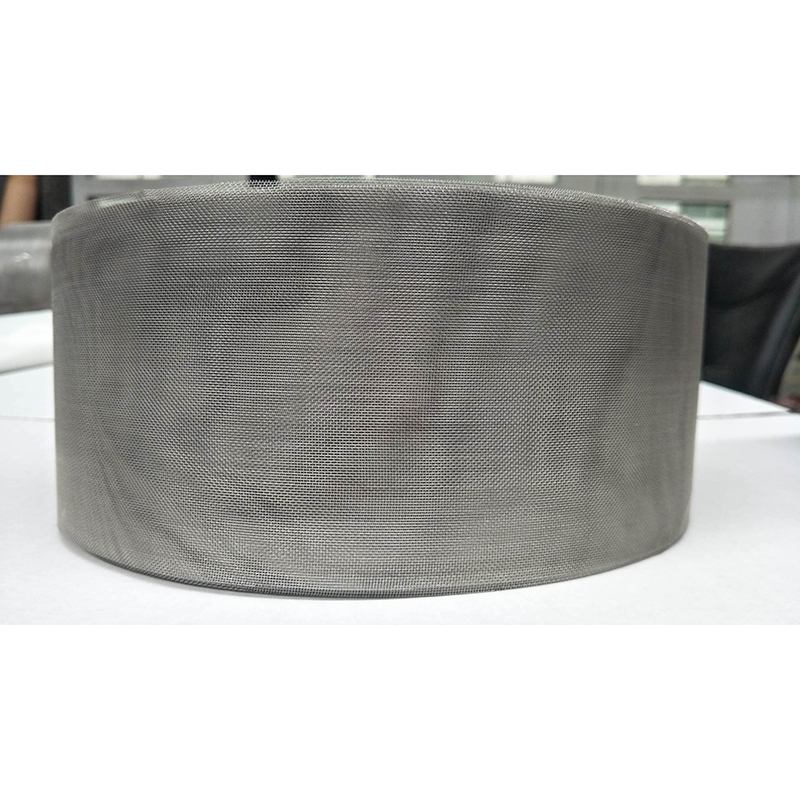

High-Quality Sintered Mesh Filter for Industrial Applications

By:Admin

Sintered mesh filters have revolutionized the way industries approach filtration, offering an efficient and cost-effective solution for a wide range of applications. As a leading manufacturer and supplier of sintered mesh filters, {company} is at the forefront of this cutting-edge technology.

{Company} has been a pioneer in the field of filtration technology for over two decades. With a commitment to research and development, the company has continuously strived to innovate and improve its products to meet the ever-evolving needs of the market. The sintered mesh filter is the latest addition to the company's extensive product line, and it has already garnered significant attention from various industries.

The sintered mesh filter is a versatile and durable filtration solution that is suitable for a diverse range of applications, including liquid and gas filtration, pharmaceuticals, food processing, petrochemical, automotive, and aerospace industries. It is designed to effectively remove contaminants and impurities from the fluid or gas flow, ensuring a clean and pure end product.

One of the key features of the sintered mesh filter is its high mechanical strength and stability. Made from multiple layers of woven wire mesh, the filter is capable of withstanding high pressures and temperatures, making it a reliable choice for demanding industrial environments. Additionally, the sintered mesh filter is resistant to corrosion, abrasion, and chemical degradation, ensuring a long service life and minimal maintenance requirements.

The advanced design of the sintered mesh filter also allows for a high flow rate and low pressure drop, ensuring efficient and smooth operation. The uniform structure of the filter media provides a consistent and reliable filtration performance, guaranteeing the quality and purity of the end product. Moreover, the sintered mesh filter can be custom-engineered to meet specific filtration requirements, offering a tailored solution for unique applications.

{Company} offers a comprehensive range of sintered mesh filters, including cylindrical, disc, basket, and cone-shaped configurations. The filters are available in various pore sizes, ranging from fine to coarse, to accommodate different filtration needs. Furthermore, the company provides additional customization options, such as material selection, dimensional specifications, and surface treatments, to ensure that the filter meets the exact requirements of the application.

In addition to its innovative product range, {company}'s commitment to quality and customer satisfaction sets it apart in the market. The company operates state-of-the-art manufacturing facilities, equipped with advanced production technologies and quality control processes, to ensure the highest standards of product excellence. Furthermore, {company} has a team of experienced engineers and application specialists who work closely with customers to understand their unique filtration challenges and provide tailored solutions.

As a global supplier, {company} is dedicated to delivering its sintered mesh filters to customers worldwide. The company has a strong distribution network and strategic partnerships in place, enabling it to offer prompt and reliable delivery services. Furthermore, {company} provides comprehensive technical support and after-sales services to ensure that customers receive the necessary assistance and guidance throughout the lifespan of the filter.

In conclusion, the sintered mesh filter from {company} represents the latest advancement in filtration technology, offering a high-performance solution for diverse industrial applications. With its exceptional durability, reliability, and customization capabilities, the sintered mesh filter is poised to become the go-to choice for businesses seeking efficient and cost-effective filtration solutions. {company} is proud to be at the forefront of this innovative technology and looks forward to continuing its mission of providing cutting-edge filtration solutions to its customers globally.

Company News & Blog

Durable Fiberglass Screen Mesh for Your Home or Business

**Company Introduction:** {The company is a leading manufacturer of building materials, specializing in the production of high-quality fiberglass screen mesh. With years of experience in the industry, the company has established a strong reputation for its commitment to innovation, quality, and customer satisfaction. Their state-of-the-art manufacturing facilities and team of dedicated professionals enable them to deliver superior products that meet the highest standards.}**News Content:**Fiberglass Screen Mesh is a key component in creating a comfortable and safe living environment, and as such, it is essential for homeowners and builders to choose a reliable and durable option. With this in mind, {Company Name} is proud to offer a range of high-quality fiberglass screen mesh products that are designed to meet and exceed the demands of modern construction projects.The {Company Name} Fiberglass Screen Mesh is a popular choice among builders and homeowners due to its exceptional strength, durability, and versatility. Made from high-quality fiberglass material, the screen mesh is designed to withstand the elements, resist tears and punctures, and provide long-lasting protection for windows, doors, and other openings.One of the key benefits of {Company Name} Fiberglass Screen Mesh is its ability to provide excellent ventilation while keeping insects and debris out. This makes it an ideal solution for screening windows, doors, and patios, allowing fresh air to flow through while maintaining a barrier against unwanted pests.In addition to its practical benefits, {Company Name} Fiberglass Screen Mesh is also designed to enhance the aesthetic appeal of any property. The mesh is available in a variety of colors and styles to complement different architectural designs, and its low-profile design ensures that it does not obstruct views or detract from the overall appearance of a building.{Company Name} understands the importance of providing reliable and durable building materials, which is why their Fiberglass Screen Mesh undergoes rigorous testing and quality control measures to ensure that it meets the highest standards. The company’s commitment to excellence is reflected in every product they manufacture, and their Fiberglass Screen Mesh is no exception.As a leading manufacturer of building materials, {Company Name} is dedicated to delivering innovative solutions that meet the evolving needs of the construction industry. Their Fiberglass Screen Mesh is just one example of their ongoing efforts to provide practical, high-quality products that contribute to the comfort and safety of residential and commercial properties.The {Company Name} Fiberglass Screen Mesh has been widely adopted by builders, contractors, and homeowners for its exceptional performance, reliability, and durability. Its versatility makes it suitable for a wide range of applications, from new construction projects to renovations and upgrades, and its popularity continues to grow as more people recognize the value it brings to their properties.With a strong focus on customer satisfaction, {Company Name} strives to make their Fiberglass Screen Mesh readily available to customers through a network of distributors and retailers. This ensures that builders and homeowners have easy access to the products they need to complete their projects with confidence and peace of mind.In conclusion, {Company Name} Fiberglass Screen Mesh is a superior choice for anyone seeking a reliable, durable, and versatile screening solution for their windows, doors, and other openings. With its exceptional strength, ventilation properties, and aesthetic appeal, it is no wonder that the product has gained widespread recognition and acclaim in the construction industry. As a testament to their commitment to quality and innovation, {Company Name} continues to offer innovative building materials that meet the highest standards and provide lasting value for their customers.

High-Quality Mesh Screen for Masterbatch: Everything You Need to Know

Mesh Screen For Masterbatch Enhances Quality and EfficiencyWith the continued growth of the plastics industry, the demand for high-quality masterbatch is on the rise. As a result, manufacturers are constantly looking for ways to improve the quality and efficiency of their masterbatch production process. One such solution that has been gaining attention is the use of mesh screens in the manufacturing process.Mesh screens are used in masterbatch production to remove impurities and improve the quality of the final product. They are made from fine metal wire that is woven into a grid pattern, and are used to filter out any unwanted particles or contaminants from the raw materials. By using mesh screens, manufacturers can ensure a higher level of purity in their masterbatch, leading to better color consistency and improved performance in end-use applications.One company that has been at the forefront of developing high-quality mesh screens for masterbatch production is {}. The company has been a leading manufacturer of mesh screens for various industries for over 20 years, and has recently introduced a new range of mesh screens specifically designed for the masterbatch industry.The mesh screens from {} are made from high-quality stainless steel wire, which is known for its durability and resistance to corrosion. This ensures that the screens can withstand the harsh conditions of the masterbatch production process, and continue to perform at a high level for an extended period of time. In addition, the screens are precision-woven to ensure a consistent and uniform mesh size, which is crucial for achieving the desired level of purity in the masterbatch.One of the key features of {}'s mesh screens for masterbatch is their high flow rate. This means that the screens allow for a higher throughput of material, without compromising on the filtration efficiency. As a result, manufacturers can achieve greater productivity and cost savings, as they can process larger volumes of raw materials in a shorter amount of time. This is especially important in the highly competitive masterbatch industry, where efficiency and productivity are key factors in staying competitive.Another advantage of using mesh screens from {} in masterbatch production is the ability to customize the mesh size according to specific requirements. This allows manufacturers to tailor the filtration process to their exact needs, and ensure that only the desired particles are removed from the raw materials. With a wide range of mesh sizes available, manufacturers can achieve the level of purity that is required for their specific masterbatch formulations.In addition to their technical capabilities, {}'s mesh screens for masterbatch are also designed with ease of use in mind. The screens are easy to install and maintain, and can be cleaned and reused multiple times without any degradation in performance. This not only reduces the overall cost of production, but also contributes to a more sustainable manufacturing process.As the demand for high-quality masterbatch continues to grow, the use of mesh screens in the production process is expected to become increasingly important. With their ability to improve the quality and efficiency of masterbatch production, mesh screens from {} are poised to play a crucial role in helping manufacturers meet the ever-increasing demands of the plastics industry. Through their commitment to quality and innovation, {} is helping to drive the industry forward, and is set to remain a trusted partner for manufacturers looking to enhance their masterbatch production process.

How installing bird screens on wire mesh cages will prevent bird problems

Wire Mesh Bird Screen: Perfect Solution for Effective Bird ControlBirds can be a nuisance, especially when they take shelter in buildings or perch on structures. Beyond the irritation that they cause, birds can be carriers of disease, cause significant damage to buildings, and pose a risk of injury to people. In some cases, they can even interfere with industrial processes and bring operations to a halt. It's for these reasons bird control is essential.A reputable company in bird control is known for its industry solutions to help organizations deal with the problem of birds. Their comprehensive range of bird control measures includes bird nets, anti-bird spikes and post and wire systems. One of their most effective solutions that have gained wide-scale recognition for its efficiency is their Wire Mesh Bird Screen.The Wire Mesh Bird Screen is an innovative solution designed to block out birds from entering buildings and roosting. The bird screen consists of a durable aluminum frame that fits snugly over an opening to prevent pest birds from entering. The screen features a durable mesh that makes it difficult for birds to land on and prevents them from accessing the area behind it.The wire mesh screen comes in a variety of sizes to fit different openings, including windows, doors, vents, and roofs. It is an effective bird control option for industries such as food processing, pharmaceuticals, and chemical industries, where it is critical to maintain cleanliness and hygiene levels. When used in conjunction with other bird control measures, it forms an essential part of any integrated bird management program.The importance of bird controlBird infestations can cause significant damage to buildings and structures, leading to increased maintenance costs for businesses. Prolonged bird infestations in food processing facilities, for example, can result in the contamination of food products, leading to severe financial consequences.Effective bird control also reduces the risk of bird-related health issues. Birds carry diseases that can harm humans, and their droppings can cause respiratory issues, especially for people with weakened immune systems or underlying health conditions.Installing bird screens as part of an overall bird management program provides a proactive way to keep bird populations under control before they become a major issue.Why Wire Mesh Bird Screens?Wire Mesh Bird Screens offer numerous benefits for controlling bird populations. Here are just a few:1. Exceptional durability: Wire mesh screens are highly durable, designed to withstand powerful hurricane winds. This attribute makes them a suitable option for businesses in areas where storms with strong winds occur frequently.2. Environmentally Friendly: Wire mesh screens promote a comfortable living environment for birds without harming them. The screens deter birds from the desired location by denying them access rather than trapping or killing them. This is a humane approach to bird control that is gaining widespread recognition around the world.3. Cost-effectiveness: Installation of bird screens is affordable compared to other measures such as trapping and netting. Also, they require minimal upkeep, allowing businesses to save on maintenance and repair expenses over the long term.4. Flexible customization: Wire mesh screens are not only available in a range of sizes to fit different openings; they can also be customized to comply with the different requirements of buildings and industrial structures.Birds can wreak havoc on buildings and pose severe health and environmental risks if left unchecked. Wire Mesh Bird Screens offer a highly effective solution to this problem by providing an eco-friendly and humane way to deter birds before they cause lasting damage.Conclusion:If your business is grappling with a bird infestation issue, you need to seek a suitable bird control solution from a reputable company. Wire Mesh Bird Screens are an ideal option as part of a comprehensive bird management program. Their durability, eco-friendliness, cost-effectiveness, and customization capabilities make them an incredible choice to keep birds outside of your business premises.

Benefits of Using Wire Screen Panels in Your Home or Office

Wire Screen Panels Improving Industrial Processes and Safety StandardsWire screen panels have revolutionized the way many industries approach their production process and safety standards. This innovative technology has not only improved the efficiency of manufacturing processes but also the safety of workers. With the advancements in manufacturing and engineering, these screens have become a popular and essential component of many industrial operations.Since the development of wire screens, companies have been eager to implement them into their processes. The screens have a wide range of applications and can be used in almost any industry sector. They are commonly used in mining, food processing, construction, and agriculture, to name just a few. They have proven to be an indispensable technology that has enabled companies to achieve higher output rates while reducing production costs.One of the primary benefits of wire screen panels is their versatility. They can be customized to fit any size and specification, making them a versatile solution for industries. This feature allows companies to create unique designs that meet their specific needs, ensuring maximum productivity and safety.In addition to their customization options, wire screen panels have a long lifespan. They are built to withstand even the most adverse conditions that industrial processes can produce. They are durable, long-lasting, and easy to maintain, ensuring that they provide a reliable and safe solution for years to come. Many companies even consider wire screens a long-term investment that pays off in spades over time.Wire screens also play a vital role in improving safety in industrial processes. By using protective screens, companies can prevent workers from getting injured by hazardous materials and machinery. This safety measure can also protect the equipment from damage, reducing the risk of costly breakdowns and maintenance repairs.Specific industries have unique needs, so it is essential for companies to use wire screen panels that are designed for their application. Wire screens come in different shapes, sizes, and materials, ensuring that they are tailored to the specific requirements of individual industries. For example, the mining industry needs different wire screen solutions than the agriculture sector or food processing.Mining companies typically require heavy-duty metal wire screens that can withstand the harsh environments they work in. These screens are designed to handle large volumes of material, typically from the extraction and processing of minerals. Additionally, they are often used in conveying machinery and as a safety mechanism to protect workers from falling debris.On the other hand, the food and beverage industry requires screens that meet strict hygiene and sanitation standards. These industries require stainless steel wire screens that are resistant to corrosion, chemical reaction, and bacterial growth. The screens must meet strict guidelines and standards of the FDA, USDA, and other regulatory bodies.Wire screens have numerous other applications in manufacturing and process engineering. They are often used to support chemical reactions, separate liquids and solids, filter waste materials, and remove impurities from mixtures. Their versatility and high customizability make them a flexible solution for different industrial applications.In conclusion, wire screen panels have revolutionized industrial processes by optimizing production rates while increasing safety standards. Their versatility and customizability have enabled them to meet the specific needs of individual industries and applications. The industry is continually evolving, and with advancements in technology, we can expect that wire screens will continue to play a crucial role in industrial processes and safety standards. Companies that utilize these screens can expect to achieve higher efficiency levels, reduced production costs, and increased worker safety, making them an essential investment for businesses worldwide.

High-Quality Aluminium Expanded Metal Mesh for Your Project Needs

Aluminium Expanded Metal Mesh has become an essential material in various industries due to its versatility and strength. This type of metal mesh is created by expanding a sheet of aluminium into a diamond pattern, resulting in a lightweight yet durable material that has a wide range of applications.With its unique properties, Aluminium Expanded Metal Mesh has been widely used in construction, architecture, and industrial applications. It provides excellent strength and rigidity, making it an ideal material for creating fences, barriers, and grilles. Additionally, its lightweight nature makes it a popular choice for decorative purposes, such as cladding and signage.One of the leading manufacturers of Aluminium Expanded Metal Mesh is {}. They have been providing high-quality metal mesh products for over 20 years, earning a reputation for their exceptional craftsmanship and innovative designs. Their Aluminium Expanded Metal Mesh is manufactured using advanced technology and strict quality control processes, ensuring that each product meets the highest standards.{} offers a wide range of Aluminium Expanded Metal Mesh products to cater to the diverse needs of their customers. Whether it's for architectural, industrial, or decorative purposes, their metal mesh products are designed to meet the specific requirements of each application. Customers can choose from a variety of patterns, thicknesses, and finishes to ensure that they get the perfect solution for their project.In addition to their standard product offerings, {} also provides custom design and fabrication services for Aluminium Expanded Metal Mesh. Their team of experienced engineers and designers can work closely with customers to develop bespoke solutions that meet their exact specifications. This level of customization sets {} apart from other suppliers, allowing them to cater to the unique needs of their clients.With a strong commitment to quality and customer satisfaction, {} has gained the trust of clients from various industries around the world. Their Aluminium Expanded Metal Mesh products have been used in a wide range of projects, from small-scale renovations to large-scale commercial developments. The durability and versatility of their metal mesh have made it a popular choice for architects, contractors, and designers alike.As a leading manufacturer of Aluminium Expanded Metal Mesh, {} is dedicated to continuously improving their products and services. They invest in research and development to stay at the forefront of industry trends and technological advancements. This commitment to innovation has enabled them to introduce new products and solutions that address the evolving needs of their customers.Overall, Aluminium Expanded Metal Mesh is a critical material in many industries, and the quality and craftsmanship of {} make them a trusted supplier in the market. Their dedication to providing high-quality products and exceptional customer service has solidified their position as a leader in the industry. With a focus on innovation and customization, {} is poised to continue meeting the diverse needs of their clients and contributing to the advancement of various industries.

New Mesh Screen Technology for Masterbatch Industry

Plastic materials are prevalent in almost every aspect of our lives, from the packaging of our favorite snacks to the interior of our cars. These plastics come in various shapes and forms, with different properties that give them unique applications. The masterbatch is one such form of plastic that is used in coloring and enhancing other polymers' properties. Masterbatch manufacturers rely on filtration technologies to achieve high-quality products, and this is where the mesh screen comes in.Leading mesh screen manufacturers such as {company name removed} have been supplying various industries with high-quality screens for decades. The company recently announced the successful testing of a mesh screen designed for masterbatch applications. The development of this new product is aimed at enhancing the quality and efficiency of masterbatch production. The increased demand for colored and functional plastics has necessitated the need for improved filtration solutions, and this new mesh screen promises to deliver just that.Masterbatch is made by combining pigments or additives with a polymer base material to achieve specific properties such as UV protection, anti-static, and flame retarding. The process of manufacturing masterbatch involves high temperatures and shear rates which makes impurities such as gels, degenerated polymers, and dirt particles a common occurrence. The presence of these impurities reduces the quality of the masterbatch and can lead to clogging of production machinery. Filtration technologies come in to remove these impurities and ensure a high-quality masterbatch. The mesh screen plays a significant role in the filtration process as it helps to remove large and small particles that can affect the quality of the final product.{Company name removed} mesh screen for masterbatch production boasts of several features that make it a reliable and efficient filtration solution. One of these features is its uniform mesh structure that ensures consistent filtration and eliminates the possibility of filtration bypass. The mesh screen is made using high-quality materials that are durable and resistant to wear and tear. This durability means that the screen can withstand prolonged exposure to high temperatures and maintain its filtration efficiency, reducing downtime and maintenance costs.Another standout feature of this mesh screen is its cleanability. The screen's design allows for easy cleaning, and the mesh structure does not trap impurities during cleaning, preventing re-contamination of the product. The cleanability feature also means that the mesh screen is reusable, reducing production costs for manufacturers. The mesh screen comes in different sizes to fit various machinery installations, making it a versatile filtration solution suitable for different masterbatch production lines.{Company name removed} has been supplying mesh screens to various industries for over 30 years and has built a reputation for quality and reliability. The company's commitment to research and development has led to the production of innovative filtration solutions that address industry challenges. The mesh screen for masterbatch production is the latest addition to the company's product line, and it promises to enhance the quality of masterbatch produced by manufacturers worldwide.In conclusion, the development of the mesh screen for masterbatch production is a significant achievement for the plastics industry. This new filtration solution promises to improve the quality and efficiency of masterbatch production, which will translate to better plastics in various applications. {Company name removed} has once again demonstrated its commitment to supplying high-quality filtration solutions to various industries, and the mesh screen for masterbatch production is a testament to this. Manufacturers can now look forward to a more reliable and efficient filtration solution for their masterbatch production, thanks to this new product.

Highly Efficient Micro Mesh Filter

Micro Mesh Filter is a leading provider of advanced filtration solutions for a wide range of industries including water treatment, oil and gas, food and beverage, pharmaceuticals, and many more. The company is dedicated to providing high-quality, innovative products that meet the most demanding filtration needs of its customers.With over 20 years of experience in the industry, Micro Mesh Filter has established a strong reputation for delivering cutting-edge filtration technologies that deliver exceptional performance and reliability. The company's commitment to quality and customer satisfaction has made it a trusted partner for companies around the world.One of the latest innovations from Micro Mesh Filter is its advanced micro mesh filter technology, which offers unparalleled levels of filtration efficiency and durability. This state-of-the-art filter is designed to capture the tiniest particles and contaminants, providing an unmatched level of purity and cleanliness.The micro mesh filter is constructed using a proprietary process that ensures uniform pore size distribution and maximum strength. This results in a filter that is highly efficient at removing even the smallest particles, making it ideal for applications where purity is critical.Another key feature of the micro mesh filter is its long service life and low maintenance requirements. The robust construction and high-quality materials used in its manufacture ensure that it can withstand even the harshest operating conditions, while still delivering consistent, reliable performance.The micro mesh filter is also designed to be easy to clean and maintain, reducing downtime and associated costs. This makes it a cost-effective solution for companies looking to minimize operational expenses while still maintaining the highest levels of filtration efficiency.Micro Mesh Filter offers a range of micro mesh filter products to suit different applications and requirements. Whether it's for water treatment, chemical processing, or food and beverage production, the company has a solution that can meet the most demanding filtration needs.In addition to its cutting-edge products, Micro Mesh Filter also provides comprehensive technical support and customer service. The company's team of filtration experts is on hand to provide advice and assistance in selecting the right filter for specific applications, as well as ongoing support to ensure optimal performance and longevity."We are proud to offer our advanced micro mesh filter technology to our customers," said a spokesperson for Micro Mesh Filter. "Our commitment to innovation and quality has enabled us to develop a filter that sets new standards for filtration efficiency and durability. We are confident that our micro mesh filter will provide significant benefits to companies across a wide range of industries."With its advanced micro mesh filter technology, combined with its extensive experience and commitment to customer satisfaction, Micro Mesh Filter continues to be a leading provider of filtration solutions for companies around the world. The company's dedication to innovation and excellence ensures that it will remain at the forefront of the industry for years to come.For more information about Micro Mesh Filter and its range of filtration solutions, visit their website at www.micromeshfilter.com.

Durable Fiberglass Screen Mesh: The Ultimate Solution for Your Home

Fiberglass Screen Mesh for Home Improvement: A New Innovation for Quality and DurabilityIn today's world, home improvement is a significant concern for many homeowners. With the ever-increasing demand for sustainable and durable building materials, the market for such products is burgeoning. Fiberglass screen mesh, a relatively new innovation in the construction industry, has been gaining widespread attention for its exemplary quality and durability.Fiberglass screen mesh is a versatile material that finds its application in a variety of construction and home improvement projects. It is made from high-quality fiberglass threads, which are woven together to form a sturdy and durable mesh. This material is known for its excellent resistance to weathering, corrosion, and chemicals, making it an ideal choice for outdoor applications such as window screens, patio enclosures, and pool fences.One of the key advantages of fiberglass screen mesh is its superior strength-to-weight ratio. This makes it an extremely lightweight yet robust material, capable of withstanding high impact and tension. Additionally, fiberglass screen mesh is highly resistant to stretching and sagging, ensuring that it maintains its form and functionality over time. This makes it an ideal choice for applications that require a long-lasting and low-maintenance solution.Furthermore, fiberglass screen mesh offers excellent visibility and airflow, allowing for a comfortable and breathable environment in the enclosed areas. Its fine mesh structure effectively keeps out insects and pests, while still allowing natural light and fresh air to pass through. This makes it an excellent choice for maintaining a pest-free and well-ventilated living space.The company {} is one of the leading manufacturers of fiberglass screen mesh, known for its commitment to quality and innovation. With years of experience in the industry, the company has established itself as a trusted supplier of high-performance building materials. Their fiberglass screen mesh products are designed to meet the highest standards of quality and durability, making them a preferred choice for homeowners, contractors, and builders alike.{} takes pride in its state-of-the-art manufacturing facilities and quality control processes, ensuring that each roll of fiberglass screen mesh meets the stringent quality standards set by the industry. Their dedicated team of engineers and technicians continuously work towards research and development to enhance the performance and durability of their products, making them a leader in the market.The company's fiberglass screen mesh comes in a variety of sizes, colors, and configurations, catering to the diverse needs of their customers. Whether it is for residential, commercial, or industrial applications, their extensive product range offers solutions for every requirement. Furthermore, their commitment to sustainability and environmental responsibility is evident in their use of eco-friendly materials and manufacturing processes, making their products an environmentally conscious choice for home improvement projects.With the rising demand for sustainable and durable building materials, fiberglass screen mesh has emerged as a reliable and cost-effective solution for homeowners and builders. Its exceptional strength, weather-resistance, and low-maintenance characteristics make it a preferred choice for applications that require long-term performance and functionality. As the market continues to evolve, fiberglass screen mesh is expected to play a pivotal role in shaping the future of home improvement and construction industry.In conclusion, with its unparalleled quality, durability, and versatility, fiberglass screen mesh has become an indispensable material for modern home improvement projects. As a leading manufacturer and supplier of fiberglass screen mesh, {} continues to set the benchmark for excellence in the industry, offering innovative solutions for sustainable and durable building materials. For homeowners looking to enhance the functionality and aesthetics of their living spaces, fiberglass screen mesh provides a reliable and cost-effective choice for a wide range of applications.

Durable and Versatile Expandable Steel Mesh for Various Applications

Expandable Steel Mesh, a new innovative product introduced by a leading steel manufacturing company, has been creating waves in the industry with its advanced technology and versatility. This revolutionary steel mesh has been developed to address the increasing demands for flexible and strong mesh solutions for various applications such as construction, industrial, and infrastructure projects.The company behind Expandable Steel Mesh, a global leader in the steel industry, has been at the forefront of producing high-quality steel products for decades. With a strong focus on research and development, the company has always aimed to introduce cutting-edge solutions that meet the evolving needs of the market. Expandable Steel Mesh is a testament to their commitment to innovation and excellence.The Expandable Steel Mesh is designed to offer superior strength and flexibility, making it an ideal choice for a wide range of applications. Its unique design allows it to be easily expanded and contracted, providing a versatile solution for different project requirements. This innovative feature sets it apart from traditional steel mesh products, making it a preferred choice for engineers, architects, and contractors.One of the key advantages of Expandable Steel Mesh is its ability to adapt to complex shapes and contours, making it suitable for challenging construction and infrastructure projects. Its flexibility allows it to be used in a variety of applications, including concrete reinforcement, slope stabilization, and tunneling. Additionally, the high tensile strength of the mesh ensures durability and stability, even in demanding environments.Moreover, Expandable Steel Mesh offers significant time and cost savings due to its easy installation and reduced material wastage. Its lightweight nature and compact storage make it convenient to transport and handle, further optimizing construction processes. This makes it an attractive choice for project managers looking to improve efficiency and productivity on-site.In addition to its practical benefits, Expandable Steel Mesh also meets rigorous industry standards for quality and performance. The company’s state-of-the-art manufacturing facilities ensure that the mesh is produced with precision and consistency, guaranteeing reliability and safety in every application. This commitment to quality has earned the company a reputation for delivering trusted solutions to its customers worldwide.The launch of Expandable Steel Mesh has been met with enthusiasm and interest from the industry, with many experts recognizing its potential to revolutionize the way steel mesh is used in construction and infrastructure projects. Its innovative design and practical advantages have positioned it as a game-changer in the market, offering new possibilities for efficient and sustainable solutions in various applications.As the demand for flexible and resilient steel mesh solutions continues to grow, Expandable Steel Mesh promises to be a crucial asset for companies and professionals looking to elevate their projects to new heights. With its exceptional adaptability, strength, and performance, it is set to become a staple in the toolkit of modern construction and infrastructure development.In conclusion, Expandable Steel Mesh is a significant addition to the company’s portfolio of cutting-edge steel solutions, showcasing their commitment to driving progress and innovation in the industry. Its advanced technology and versatility make it a valuable asset for meeting the evolving needs of modern construction and infrastructure projects, setting a new standard for excellence in steel mesh solutions. As the company continues to push boundaries and redefine possibilities, Expandable Steel Mesh stands as a testament to their dedication to shaping a better, more resilient future.

Innovative Mesh Screen for Masterbatch: What You Need to Know

In the world of plastic production, [Company Name] is a well-known and reputable company specializing in the manufacturing of masterbatch. With a commitment to innovation and excellence, [Company Name] continuously seeks to improve its product offerings and provide the best solutions for its customers. Recently, the company has introduced a new mesh screen for its masterbatch production, aiming to enhance the quality and efficiency of its products.The new mesh screen is a significant development for [Company Name], as it represents a shift towards more advanced and precise manufacturing processes. This innovation is a result of extensive research and development efforts, as well as a strong dedication to meeting the needs of their customers. The mesh screen is designed to improve the dispersion of additives in the masterbatch, ensuring a more uniform and consistent product.One of the key benefits of the new mesh screen is its ability to enhance the quality of the masterbatch produced by [Company Name]. By ensuring better dispersion of additives, the mesh screen leads to improved performance and appearance of the final plastic products. This is particularly important for customers who rely on [Company Name] for high-quality masterbatch to meet their unique production requirements.Moreover, the introduction of the mesh screen demonstrates [Company Name]'s commitment to sustainability and environmental responsibility. By improving the dispersion of additives, the company can reduce the amount of additives required in the masterbatch production process, resulting in a more environmentally friendly approach to plastic manufacturing. This aligns with [Company Name]'s broader efforts to minimize its environmental footprint and contribute to a more sustainable industry.To ensure the successful implementation of the new mesh screen, [Company Name] has made significant investments in its manufacturing facilities and processes. The company has upgraded its production lines to accommodate the new technology, as well as provided comprehensive training to its staff to ensure seamless integration. This investment reflects [Company Name]'s dedication to staying at the forefront of the industry and delivering the best possible products to its customers.In addition to the technical advancements, [Company Name] has also focused on optimizing the overall customer experience. The introduction of the mesh screen is part of a larger effort to enhance the company's product offerings and provide more value to its customers. By improving the quality and consistency of its masterbatch, [Company Name] aims to strengthen its position as a trusted partner for plastic manufacturers, both domestically and internationally.Looking ahead, [Company Name] is committed to further innovation and improvement in its product offerings. The introduction of the mesh screen is just one example of the company's ongoing efforts to push the boundaries of what is possible in plastic production. With a strong focus on research, development, and customer collaboration, [Company Name] is well positioned to continue providing cutting-edge solutions to meet the evolving needs of the industry.In conclusion, the introduction of the new mesh screen for masterbatch production represents a significant step forward for [Company Name]. This innovation not only improves the quality and efficiency of its products but also reflects the company's dedication to sustainability and customer satisfaction. With a strong commitment to excellence and a focus on continuous improvement, [Company Name] is poised to maintain its leadership position in the plastic manufacturing industry.