Welded Mesh: A strong and versatile option for a variety of applications

By:Admin

Introduction (98 words):

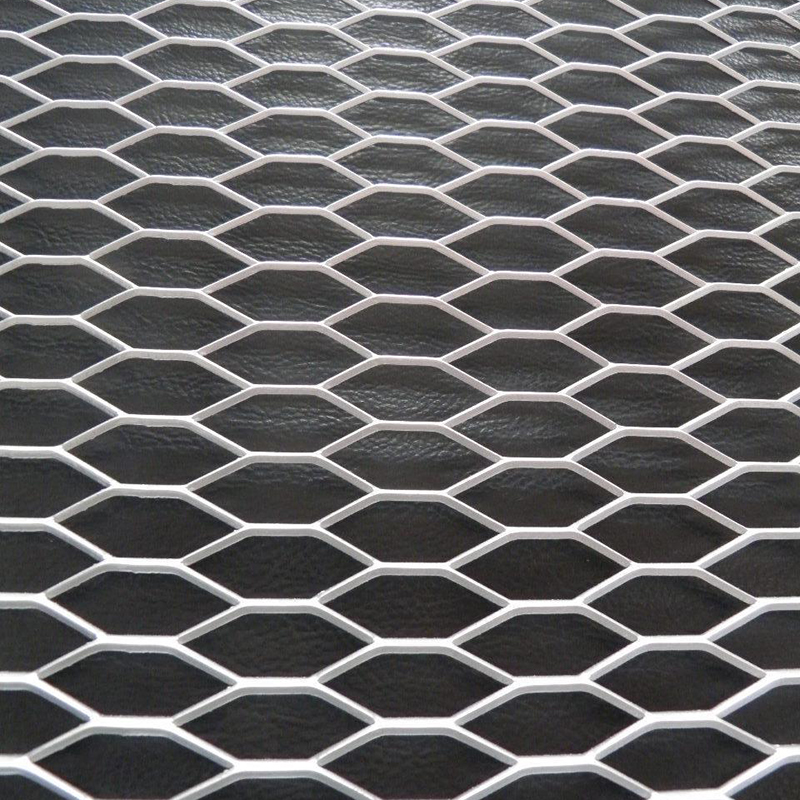

In recent years, the industrial sector has experienced a significant shift towards utilizing advanced materials and innovative solutions to meet the evolving demands of modern manufacturing processes. One such groundbreaking development is the introduction of Mild Steel Welded Mesh, an exceptionally robust and versatile material. This article aims to explore the various applications and benefits of Mild Steel Welded Mesh, discussing its exceptional structural properties, durability, and increased cost-efficiency. As industries seek solutions that streamline production while ensuring safety and resilience, the introduction of this revolutionary mesh presents an exciting new chapter in industrial progress.

1. Overview of Mild Steel Welded Mesh (119 words):

Mild Steel Welded Mesh is a high-quality metal grid constructed using low-carbon mild steel wires, expertly welded together to form a strong and flexible mesh pattern. Made from mild steel, this type of mesh possesses superior strength and durability, making it an ideal choice for a wide range of industrial applications. Its innovate design provides structural reinforcement, excellent impenetrability, and reduced maintenance requirements. With its uniform grid pattern, Mild Steel Welded Mesh is also characterized by its enhanced load-bearing capacity and exceptional resistance to impact, corrosion, and extreme weather conditions. These attributes, alongside its affordability, render it a highly sought-after solution across various industries.

2. Industrial Applications of Mild Steel Welded Mesh (209 words):

2.1 Enhanced Safety and Security: Mild Steel Welded Mesh is widely employed in fencing systems, where it acts as a protective barrier for factories, warehouses, and other industrial premises. Its rigid construction deters trespassing attempts while maintaining visibility and providing adequate ventilation.

2.2 Reinforced Construction and Concrete Slabs: Due to its remarkable strength, Mild Steel Welded Mesh is used in the construction industry to reinforce concrete slabs, walls, and columns, offering structural stability and increasing load-bearing capacity. This application finds particular utility in erecting commercial buildings, bridges, and tunnels.

2.3 Advancements in Infrastructure: The implementation of Mild Steel Welded Mesh in the development of highways, railways, and flyover bridges has revolutionized infrastructure projects. Its corrosion-resistant properties ensure longevity and cost-effectiveness, making it an ideal choice for these large-scale construction projects.

2.4 Automation and Robotics: The manufacturing industry relies heavily on Mild Steel Welded Mesh for the construction of customized industrial equipment, automation systems, and robotics components. The precise grid pattern facilitates the integration of mechanical parts, ensuring accuracy, durability, and optimal functionality.

2.5 Environmental Applications: Mild Steel Welded Mesh is also used in ecological projects like land reclamation, coastal defense, and protection of vegetation against animals. Its strength and flexibility are instrumental in maintaining ecological balance, preventing erosion, and safeguarding sensitive habitats.

3. Advantages and Benefits of Mild Steel Welded Mesh (177 words):

The adoption of Mild Steel Welded Mesh offers several advantages over traditional materials, driving its growing popularity among various industries. Some key benefits include:

3.1 Versatility: Mild Steel Welded Mesh boasts a versatile design that can be customized to meet specific requirements, allowing for a wide range of applications across diverse industries.

3.2 Cost-Efficiency: Compared to alternatives, Mild Steel Welded Mesh presents a cost-effective solution by reducing material and labor costs, ultimately improving profitability.

3.3 Durability and Longevity: Its exceptional structural properties provide outstanding durability and longevity, requiring minimal maintenance and replacement.

3.4 Enhanced Safety: The welded construction of the mesh ensures high levels of safety by preventing collapses, safeguarding workers, and reducing the likelihood of unauthorized access.

3.5 Eco-Friendly Solution: As an environmentally-friendly option, Mild Steel Welded Mesh is recyclable and sustainable, contributing positively to organizations' green initiatives.

Conclusion (89 words):

The emergence of Mild Steel Welded Mesh presents a game-changing advancement in the industrial sector, offering a host of benefits and applications that enhance safety, efficiency, and sustainability. This highly versatile material is poised to revolutionize various industries, from construction and manufacturing to infrastructure development and environmental restoration. As industries continue to push boundaries and seek innovative solutions, the adoption of Mild Steel Welded Mesh is set to become a standard practice, setting the stage for a more resilient, cost-effective, and environmentally-conscious future in industrial applications.

Company News & Blog

How installing bird screens on wire mesh cages will prevent bird problems

Wire Mesh Bird Screen: Perfect Solution for Effective Bird ControlBirds can be a nuisance, especially when they take shelter in buildings or perch on structures. Beyond the irritation that they cause, birds can be carriers of disease, cause significant damage to buildings, and pose a risk of injury to people. In some cases, they can even interfere with industrial processes and bring operations to a halt. It's for these reasons bird control is essential.A reputable company in bird control is known for its industry solutions to help organizations deal with the problem of birds. Their comprehensive range of bird control measures includes bird nets, anti-bird spikes and post and wire systems. One of their most effective solutions that have gained wide-scale recognition for its efficiency is their Wire Mesh Bird Screen.The Wire Mesh Bird Screen is an innovative solution designed to block out birds from entering buildings and roosting. The bird screen consists of a durable aluminum frame that fits snugly over an opening to prevent pest birds from entering. The screen features a durable mesh that makes it difficult for birds to land on and prevents them from accessing the area behind it.The wire mesh screen comes in a variety of sizes to fit different openings, including windows, doors, vents, and roofs. It is an effective bird control option for industries such as food processing, pharmaceuticals, and chemical industries, where it is critical to maintain cleanliness and hygiene levels. When used in conjunction with other bird control measures, it forms an essential part of any integrated bird management program.The importance of bird controlBird infestations can cause significant damage to buildings and structures, leading to increased maintenance costs for businesses. Prolonged bird infestations in food processing facilities, for example, can result in the contamination of food products, leading to severe financial consequences.Effective bird control also reduces the risk of bird-related health issues. Birds carry diseases that can harm humans, and their droppings can cause respiratory issues, especially for people with weakened immune systems or underlying health conditions.Installing bird screens as part of an overall bird management program provides a proactive way to keep bird populations under control before they become a major issue.Why Wire Mesh Bird Screens?Wire Mesh Bird Screens offer numerous benefits for controlling bird populations. Here are just a few:1. Exceptional durability: Wire mesh screens are highly durable, designed to withstand powerful hurricane winds. This attribute makes them a suitable option for businesses in areas where storms with strong winds occur frequently.2. Environmentally Friendly: Wire mesh screens promote a comfortable living environment for birds without harming them. The screens deter birds from the desired location by denying them access rather than trapping or killing them. This is a humane approach to bird control that is gaining widespread recognition around the world.3. Cost-effectiveness: Installation of bird screens is affordable compared to other measures such as trapping and netting. Also, they require minimal upkeep, allowing businesses to save on maintenance and repair expenses over the long term.4. Flexible customization: Wire mesh screens are not only available in a range of sizes to fit different openings; they can also be customized to comply with the different requirements of buildings and industrial structures.Birds can wreak havoc on buildings and pose severe health and environmental risks if left unchecked. Wire Mesh Bird Screens offer a highly effective solution to this problem by providing an eco-friendly and humane way to deter birds before they cause lasting damage.Conclusion:If your business is grappling with a bird infestation issue, you need to seek a suitable bird control solution from a reputable company. Wire Mesh Bird Screens are an ideal option as part of a comprehensive bird management program. Their durability, eco-friendliness, cost-effectiveness, and customization capabilities make them an incredible choice to keep birds outside of your business premises.

Welded Mesh: A strong and versatile option for a variety of applications

Title: Advancements in Mild Steel Welded Mesh Revolutionize Industrial ApplicationsIntroduction (98 words):In recent years, the industrial sector has experienced a significant shift towards utilizing advanced materials and innovative solutions to meet the evolving demands of modern manufacturing processes. One such groundbreaking development is the introduction of Mild Steel Welded Mesh, an exceptionally robust and versatile material. This article aims to explore the various applications and benefits of Mild Steel Welded Mesh, discussing its exceptional structural properties, durability, and increased cost-efficiency. As industries seek solutions that streamline production while ensuring safety and resilience, the introduction of this revolutionary mesh presents an exciting new chapter in industrial progress.1. Overview of Mild Steel Welded Mesh (119 words):Mild Steel Welded Mesh is a high-quality metal grid constructed using low-carbon mild steel wires, expertly welded together to form a strong and flexible mesh pattern. Made from mild steel, this type of mesh possesses superior strength and durability, making it an ideal choice for a wide range of industrial applications. Its innovate design provides structural reinforcement, excellent impenetrability, and reduced maintenance requirements. With its uniform grid pattern, Mild Steel Welded Mesh is also characterized by its enhanced load-bearing capacity and exceptional resistance to impact, corrosion, and extreme weather conditions. These attributes, alongside its affordability, render it a highly sought-after solution across various industries.2. Industrial Applications of Mild Steel Welded Mesh (209 words):2.1 Enhanced Safety and Security: Mild Steel Welded Mesh is widely employed in fencing systems, where it acts as a protective barrier for factories, warehouses, and other industrial premises. Its rigid construction deters trespassing attempts while maintaining visibility and providing adequate ventilation.2.2 Reinforced Construction and Concrete Slabs: Due to its remarkable strength, Mild Steel Welded Mesh is used in the construction industry to reinforce concrete slabs, walls, and columns, offering structural stability and increasing load-bearing capacity. This application finds particular utility in erecting commercial buildings, bridges, and tunnels.2.3 Advancements in Infrastructure: The implementation of Mild Steel Welded Mesh in the development of highways, railways, and flyover bridges has revolutionized infrastructure projects. Its corrosion-resistant properties ensure longevity and cost-effectiveness, making it an ideal choice for these large-scale construction projects.2.4 Automation and Robotics: The manufacturing industry relies heavily on Mild Steel Welded Mesh for the construction of customized industrial equipment, automation systems, and robotics components. The precise grid pattern facilitates the integration of mechanical parts, ensuring accuracy, durability, and optimal functionality.2.5 Environmental Applications: Mild Steel Welded Mesh is also used in ecological projects like land reclamation, coastal defense, and protection of vegetation against animals. Its strength and flexibility are instrumental in maintaining ecological balance, preventing erosion, and safeguarding sensitive habitats.3. Advantages and Benefits of Mild Steel Welded Mesh (177 words):The adoption of Mild Steel Welded Mesh offers several advantages over traditional materials, driving its growing popularity among various industries. Some key benefits include:3.1 Versatility: Mild Steel Welded Mesh boasts a versatile design that can be customized to meet specific requirements, allowing for a wide range of applications across diverse industries.3.2 Cost-Efficiency: Compared to alternatives, Mild Steel Welded Mesh presents a cost-effective solution by reducing material and labor costs, ultimately improving profitability.3.3 Durability and Longevity: Its exceptional structural properties provide outstanding durability and longevity, requiring minimal maintenance and replacement.3.4 Enhanced Safety: The welded construction of the mesh ensures high levels of safety by preventing collapses, safeguarding workers, and reducing the likelihood of unauthorized access.3.5 Eco-Friendly Solution: As an environmentally-friendly option, Mild Steel Welded Mesh is recyclable and sustainable, contributing positively to organizations' green initiatives.Conclusion (89 words):The emergence of Mild Steel Welded Mesh presents a game-changing advancement in the industrial sector, offering a host of benefits and applications that enhance safety, efficiency, and sustainability. This highly versatile material is poised to revolutionize various industries, from construction and manufacturing to infrastructure development and environmental restoration. As industries continue to push boundaries and seek innovative solutions, the adoption of Mild Steel Welded Mesh is set to become a standard practice, setting the stage for a more resilient, cost-effective, and environmentally-conscious future in industrial applications.

Top Quality Welded Mesh Fencing for Your Property Security Needs

[News Title]: Innovative Roll Top Weld Mesh Fencing Revolutionizes Boundary Security[Dateline]: [City], [Date] – An innovative solution in fencing security has been introduced by an industry-leading company, [Company Name], known for its commitment to excellence and cutting-edge designs. Roll Top Weld Mesh Fencing, the latest addition to their product line, is set to revolutionize boundary security with its unparalleled strength, durability, and aesthetic appeal.[Company Name], established in [year], has consistently been at the forefront of fence manufacturing. With a team of dedicated engineers and designers, the company focuses on creating products that meet the evolving needs of varied industries, from residential and commercial to industrial and agricultural.The newly launched Roll Top Weld Mesh fencing system provides a superior solution for securing boundaries due to its advanced design and construction. Constructed from high-quality galvanized steel wires, the fence panels are welded together to form a sturdy and impenetrable mesh structure. The weld mesh design utilizes a unique roll top feature, ensuring the edges of the mesh are smooth and safe to prevent injuries while maintaining maximum security.One of the main advantages of this innovative fencing system is its flexibility. The fence panels can be easily adjusted to fit any terrain, including hilly or uneven landscapes, thanks to their ability to either step or rake down with the contour of the land. This adaptability makes the Roll Top Weld Mesh Fencing an ideal choice for a wide range of applications, from securing gardens and residential properties to enclosing parks, schools, sports fields, and commercial facilities.The company's commitment to quality is evident in every aspect of the Roll Top Weld Mesh Fencing system. The galvanized steel construction ensures exceptional durability, making it resistant to harsh weather conditions, corrosion, and impacts. This longevity translates into a cost-effective investment for customers, who can rely on the fence's durability and reliability for many years to come.Additionally, the premium finish of the fencing panels adds an aesthetic appeal to any environment. The smooth and unobtrusive design seamlessly blends with the surroundings, enhancing the overall appearance of the property. This feature makes the Roll Top Weld Mesh Fencing an ideal choice for those seeking both security and aesthetic coherence.[Company Name] takes pride in its commitment to customer satisfaction, and the introduction of the new fencing system is no exception. The company offers a comprehensive service that covers the entire process, from the initial design consultation to installation and maintenance. Their experienced team of professionals ensures a seamless experience for customers, providing expert advice and guidance every step of the way.With the launch of the Roll Top Weld Mesh Fencing, [Company Name] aims to maintain its position as an industry leader by offering its customers an innovative and practical solution for their boundary security needs. The fencing system's strength, adaptability, durability, and aesthetic appeal make it the ideal choice for a wide range of applications, providing peace of mind and enhancing the visual appeal of properties.Building on its reputation for excellence, [Company Name] continues to strive for innovation and continually improve its product offerings to meet the evolving needs of its customers. The Roll Top Weld Mesh Fencing is a testament to the company's dedication to creating cutting-edge solutions that redefine the standards of boundary security.For more information on the Roll Top Weld Mesh Fencing and other products offered by [Company Name], please visit their official website or reach out to their customer service representatives.

Welded Wire Mesh Gauge: Understanding the Different Gauges for Various Applications

Welded Wire Mesh Gauge: The Promise of Quality and DurabilityWelded wire mesh gauge has been an essential material used in various construction and industrial applications around the world. It has become increasingly popular due to its excellent durability and convenient installation process. Industries that require reinforcing materials often rely on welded wire mesh to provide the strength and stability that they need.One of the companies that offer high-quality welded wire mesh gauge is [company name removed], a leading manufacturer of reinforcing steel products, with over [number] years of experience in the industry. The company takes pride in its ability to produce highly durable materials that meet even the most stringent industry standards.[Company name removed] offers three main types of welded wire mesh gauges: galvanized, PVC-coated, and stainless-steel. Each type of gauge has unique characteristics and properties that make it suitable for specific applications.Galvanized welded wire mesh gauge is a popular choice in construction and industrial applications because of its rust-resistant properties. It's made of high-quality steel, which is dipped in liquid zinc for added protection. This process creates a barrier between the steel and the elements, making it highly resistant to corrosion.PVC-coated welded wire mesh gauge is an excellent option for industries that require a high level of aesthetic appeal, such as in the creation of garden fences, animal enclosures, and DIY projects. The PVC coating provides an extra layer of protection and also enhances the appearance of the material. It's available in different colors to help match the aesthetics of any design project.Stainless-steel welded wire mesh gauge is suitable for industries that require maximum protection against corrosion and rust. It's made of high-quality stainless steel that offers excellent strength and durability. It's ideal for use in marine environments or places that are highly exposed to moisture, saltwater, or chemicals.[Company name removed] takes pride in its ability to produce high-quality welded wire mesh gauges that meet various industry standards. Each product undergoes a rigorous testing process to ensure that it meets the required specifications and quality standards.The company uses top-of-the-line technology and equipment in the manufacturing process to ensure that every product is produced to the highest quality standards. They also have a team of highly skilled professionals who are trained to handle every aspect of the manufacturing process, from design to production, to ensure that every product is of the highest quality.In addition to producing high-quality products, [company name removed] also offers excellent customer service. They take pride in providing personalized services to their clients, such as customizing orders, providing technical support, and offering expert advice on the best products for specific applications.Furthermore, the company is committed to sustainability and environmental consciousness. They use eco-friendly and recyclable materials in their products and adopt practices that minimize waste and reduce their carbon footprint. This commitment to sustainability has earned them a reputation as a socially responsible and environmentally conscious company.In conclusion, [company name removed] is a trustworthy and reliable manufacturer of welded wire mesh gauges. Its commitment to quality, customer service, and environmental consciousness has made them a recognized and respected name in the industry. With their extensive range of products and technical expertise, they are well-equipped to meet the need of various industries for high-quality, durable, and reliable reinforcing materials.

Discover the Benefits of 200 Micron Mesh Screen for Various Applications

Title: Groundbreaking 200 Micron Mesh Screen Revolutionizes Filtration TechnologyIntroduction:In a significant breakthrough, a leading filtration technology company has unveiled a new innovation that will transform the industry. With their introduction of a groundbreaking 200 Micron Mesh Screen, the company aims to revolutionize the way filtration systems operate. By combining advanced engineering techniques with cutting-edge materials, this revolutionary product offers unprecedented filtering capabilities across various applications.Paragraph 1: The 200 Micron Mesh Screen represents a major leap forward in filtration technology. This finely woven screen effectively strains out particles as small as 200 microns. By comparison, a human hair is approximately 100 microns in diameter, demonstrating the remarkable precision and efficiency of the screen. This breakthrough solution enables industries to achieve superior filtration, enhancing productivity, quality control, and environmental sustainability.Paragraph 2: The innovative design of the mesh screen allows for enhanced durability and performance. The company leveraged its expertise in engineering and material science to develop a solution that is robust, yet flexible, ensuring long-term reliability in various demanding applications. This break-resistant screen sets a new standard for filtering efficiency, enabling customers to achieve exceptional results while minimizing maintenance costs.Paragraph 3: The wide range of applications for the 200 Micron Mesh Screen ensures its relevance across diverse industries. From water treatment plants to food processing facilities, this versatile product addresses the filtration needs of numerous sectors. The screen's ability to effectively remove impurities, such as sediment, debris, or contaminants, makes it an invaluable asset in maintaining product integrity and meeting regulatory standards.Paragraph 4: Furthermore, the mesh screen's high-performance capabilities offer significant advantages compared to traditional filtration systems. Its increased filtration capacity allows for a higher flow rate, reducing processing time and enhancing overall operational efficiency. With reduced clogging and improved particle retention, the screen offers superior filtration performance, providing businesses with a competitive edge.Paragraph 5: The environmentally friendly nature of the 200 Micron Mesh Screen adds to its appeal. By removing particles as small as 200 microns, this solution minimizes biofouling, extending the lifespan of downstream filtration equipment and reducing the frequency of maintenance interventions. The screen's durability also contributes to sustainability efforts by reducing material waste, enhancing the product's lifecycle, and promoting responsible resource management.Paragraph 6: The successful development of the 200 Micron Mesh Screen showcases the company''s commitment to innovation and its prowess in pushing boundaries within the filtration industry. With numerous patents and a team of dedicated experts, the company continues to strive for new advancements that will redefine the industry's standards and meet evolving customer demands.Conclusion:The unveiling of the 200 Micron Mesh Screen marks a pivotal moment in the filtration industry. Customers across various sectors can now expect unparalleled filtration performance, reduced downtime, and enhanced sustainability. This revolutionary product showcases the company's dedication to pushing boundaries, heralding a new era of filtration technology. With improved efficiency, durability, and flexibility, the 200 Micron Mesh Screen sets a new benchmark for filtration systems, empowering businesses to achieve greater productivity, profitability, and environmental responsibility.

Discover the Benefits of 40 Mesh Screens

As the demand for a healthier lifestyle increases, people are becoming more aware of the potential dangers of inhaling various pollutants present in the air. Various filtration methods have been used to control indoor air quality, such as HVAC systems, air purifiers, and air filters. However, not all filters can effectively capture fine particles, which may still cause serious health problems. In this context, a new solution is on the horizon: the 40 mesh screen. This innovative product is designed to capture fine particles that other filters simply cannot handle, improving indoor air quality significantly. One of the leading companies producing 40 mesh screens is committed to providing consumers with the highest-quality products that meet their specific requirements. These screens are made with top-grade materials and innovative manufacturing processes that ensure high efficiency and cost-effectiveness. One of the main features of 40 mesh screens is that they use a sophisticated mesh design, which traps particles larger than 40 microns in size with great efficiency. This not only improves indoor air quality but also improves the performance of heating and cooling systems by keeping the air ducts clean. The company behind this breakthrough technology has been working for over a decade to develop and perfect these screens. They use advanced manufacturing processes to ensure that each screen is of consistent quality and meets strict industry standards. This is why their 40 mesh screens have gained a reputation as one of the most effective, reliable, and economical air filtration solutions on the market. One its unique features is that the company's 40 mesh screens are available in a wide range of sizes and specifications to suit different needs and preferences. Whether you need a specific size for your HVAC system or custom-designed screens for your air purifiers or other filtration systems, they have you covered. One of the other advantages of using their 40 mesh screens is that they are incredibly durable and require little maintenance. Once installed, they can provide long-lasting protection against contaminants for years. Moreover, these screens are washable and can be used repeatedly, which further reduces the overall cost of air filtration. The benefits of using 40 mesh screens go beyond just improving indoor air quality. They can also provide significant energy savings, by reducing the load on HVAC systems as well as improving the performance of air purifiers. This can lead to lower energy bills and a greener environment. One of the challenges that the company has faced is the initial cost of installing a 40 mesh screen. However, the long-term benefits of these screens more than make up for the cost. Many consumers choose to install them as a long-term investment in their health and wellbeing. To meet the growing demand for their products, the company is continuously investing in new manufacturing technology and talent. They are committed to staying ahead of the curve and providing their customers with the latest and most cutting-edge air filtration solutions. In conclusion, as people become more conscious of the potential dangers of inhaling indoor pollutants, the demand for effective air filtration solutions is set to increase. Companies like the one responsible for the development of 40 mesh screens are leading the way in providing innovative, reliable, and efficient products that can make a real difference in people's lives. With their unwavering commitment to quality and customer satisfaction, it is no surprise that 40 mesh screens have become a go-to solution for many people looking to improve indoor air quality, reduce energy costs, and live healthier lives.

The Importance of Sintered Bronze Filters for Your Needs

Sintered Bronze Filter Proves Efficiency and Trustworthiness in Numerous ApplicationsElectronics, automotive, aerospace and medical industries among others require components that could withstand harsh environmental conditions and continue to perform with consistent efficiency. One such component that plays a role in the smooth functioning of these industries is the Sintered Bronze Filter. This filter has the ability to remove contaminants in a way that other filters cannot accomplish. Composed of interconnected spheres of bronze powder that are compressed and heated, the Sintered Bronze Filter ensures that any foreign material that could interfere with the performance of an element is eliminated. This technology allows the filter in question to be very efficient with a high level of porosity, which makes it possible for the filter to efficiently filter fluids and gases.The Sintered Bronze Filter technology has been applied to various applications in different fields of industry. Such industries include medical, automotive, aerospace, food and beverage processing, wastewater treatment, oil, and gas recovery, just to mention a few. For instance, one of the world's leading engines and automotive manufacturer relies on the filter for their fuel management systems, while top pharmaceutical companies use the Sintered Bronze Filter for various medical applications.The medical industry also relies heavily on this groundbreaking technology, especially when handling fluids and gasses that should meet purified standards. Medical gases contain impurities that could be life-threatening when used in various medical procedures. Therefore, the Sintered Bronze Filter is highly effective in combating the same and providing safe and clean medical gases. Also, hospitals depend on the Sintered Bronze Filter in sterilization processes, for example, before packaging surgical equipment.The aerospace industry has also not been left behind when it comes to the versatility of the Sintered Bronze Filter. The requirements of this industry in terms of durability, temperature resistance, and strength can only be found in a few filters. This filter's unique ability to work in high-temperature environments is what makes it stand out in the aerospace industry, where temperature goes beyond the boiling point of water. It has applications in air conditioning, hydraulic servo control, lubrication, and pressure control and regulation.Food and beverage processing companies have also relied on the Sintered Bronze Filter, especially when working with liquids. This filter is preferred because it is both heat and corrosion-resistant, allowing it to work efficiently with any fluid regardless of their chemical composition. The wine production industry, for instance, requires filters that can withstand the acidity and pressure during fermentation. The Sintered Bronze Filter has been a tool that food and beverage processing industries use to produce the best products consistently.The increased popularity of the Sintered Bronze Filter can be attributed to its reliability and efficiency. Industries that had to switch between different types of filters to meet their needs can now rely on this single filter type. The long-lasting durability, ease of cleaning, and the fact that it can stand up to harsh environments have made it the most sought-after filtration technology in many industries. Companies that rely on the filter will not need a backup filter to include in their inventory, ultimately reducing their operational costs.The efficiency of the Sintered Bronze Filter has led to partnerships with some of the leading companies in various industries. Companies specializing in filtration components have adopted the Sintered Bronze Filter in their product lines, allowing customizations to suit customers' specific needs. The filter has been used in custom-sized filters to whole filter cartridges, bag filters, and more. In conclusion, the Sintered Bronze Filter has revolutionized the filtration industry due to its ability to work efficiently in harsh environmental conditions. As industries continue to grow and advance, the need for stable and long-lasting filters becomes essential. The Sintered Bronze Filter provides a solution since it is both reliable and efficient. Its technology has been embraced in numerous industries, and companies appreciate the value it adds to their process. This filter is, therefore, becoming the most preferred filtration technology in multiple applications, from medical to aerospace.

Discover the Latest Tube Filter Mesh Innovations from China

Title: Chinese Tube Filter Mesh: A Breakthrough in Manufacturing High-Quality FiltersIntroduction:In recent news, China has made significant strides in the manufacturing industry with the development of a remarkable innovation – Tube Filter Mesh (name removed). This groundbreaking technology is reshaping the production of high-quality filters, revolutionizing numerous sectors worldwide. Through its unique manufacturing process, Tube Filter Mesh promises to deliver enhanced filtration efficiency, durability, and cost-effectiveness. Let's delve deeper into this remarkable invention and explore its potential implications.1. What is Tube Filter Mesh?Tube Filter Mesh is a state-of-the-art filtration system designed to improve the efficiency and effectiveness of diverse filtering applications. It is manufactured using advanced techniques that combine precision engineering, high-quality materials, and innovative design. With its exceptional attributes, Tube Filter Mesh has the potential to meet the growing global demand for reliable filtration solutions across various industries.2. Manufacturing Process:The production of Tube Filter Mesh involves a complex and meticulous manufacturing process, ensuring that the final product meets the highest industry standards. The process starts with the selection of premium-grade raw materials, such as stainless steel or other corrosion-resistant alloys, which provide the mesh with exceptional strength and durability.Next, these selected materials undergo a series of advanced precision cutting and welding techniques. These processes ensure that the mesh tubes are accurately formed, with consistent pore sizes, allowing for precise filtration. The use of automated machinery guarantees the highest level of uniformity throughout the manufacturing process.To further enhance the filtration capabilities, Tube Filter Mesh can be customized with various surface coatings to achieve specific functions. These coatings may include anti-corrosion layers, heat resistance, or even specialized coatings for specific industries, such as oil and gas or food processing.3. Advantages of Tube Filter Mesh:a. Enhanced Filtration Efficiency: The unique structure of Tube Filter Mesh allows for the maximization of filtration area and minimization of pressure drops during the filtration process. This results in improved filtration efficiency and reduced energy consumption.b. Increased Durability: The use of high-quality materials and precise manufacturing techniques ensures that Tube Filter Mesh boasts exceptional durability and longevity. Its resistance to corrosion, high temperatures, and mechanical stress makes it an ideal choice for challenging filtration applications.c. Customizability: Tube Filter Mesh can be tailored to meet specific filtration requirements, allowing for customization in terms of pore size, surface coatings, and dimensions. This flexibility enables the use of Tube Filter Mesh in a wide range of industries, including automotive, chemical, pharmaceutical, and water treatment.d. Cost-Effectiveness: The advanced manufacturing techniques used in the production of Tube Filter Mesh allow for efficient and cost-effective mass production. This, combined with its extended lifespan, reduces operating costs for businesses relying on filtration systems, making it a financially attractive option.4. Market Implications:The introduction of Tube Filter Mesh to the global market is expected to have far-reaching implications across various industries. Its superior filtration capabilities, extended lifespan, and cost-effectiveness position it as a crucial component for industries requiring efficient and reliable filtration solutions. This includes sectors such as wastewater treatment, oil and gas, food processing, and many more.Furthermore, as China continues to expand its presence in the global manufacturing industry, the development and export of Tube Filter Mesh will contribute to further strengthening the country's role as a technological leader and innovator.Conclusion:The emergence of the Tube Filter Mesh in China represents a significant breakthrough in the manufacturing of high-quality filters. Its exceptional filtration efficiency, durability, customizability, and cost-effectiveness make it a valuable asset for various industries worldwide. This remarkable technological advancement positions China at the forefront of innovation in the manufacturing sector, promising a brighter future for reliable and efficient filtration systems.

Replace Your Hydraulic Filter Mesh for Optimal Performance

Hydraulic Filter Mesh: Enhancing Efficiency and ReliabilityHydraulic systems play a crucial role in various industries, ensuring smooth operations and efficient performance. To maintain the optimal functionality of these systems, the use of high-quality hydraulic filters is essential. Among the most reliable and effective options available in the market is the Hydraulic Filter Mesh, which has gained significant recognition for its efficiency and reliability.The Hydraulic Filter Mesh, manufactured by a leading company in the industry, is designed to offer exceptional filtration performance in hydraulic systems. It is developed using advanced technology and high-quality materials to ensure durability and longevity. This innovative filter mesh is suitable for a wide range of applications, including automotive, industrial, and construction sectors.One of the key features that sets the Hydraulic Filter Mesh apart from other filters is its filtering capability. With a precise and intricate mesh design, it effectively captures and removes contaminants from hydraulic fluids, such as dirt, debris, and metal shavings. This ensures that the hydraulic system operates smoothly and prevents any damage to the components or machinery.Furthermore, the Hydraulic Filter Mesh offers a high level of efficiency and reliability. Its fine mesh structure enables the filtration of particles as small as a few microns, guaranteeing clean and debris-free hydraulic fluids. This enhances the overall performance of the system and reduces the risk of system failures or breakdowns.The durability of the Hydraulic Filter Mesh is another notable aspect that sets it apart. Constructed with robust materials, it remains functional even under extreme operating conditions, such as high pressure and temperature. This durability ensures a longer lifespan, reducing the need for frequent replacements and maintenance, thus saving both time and costs for the users.In addition to its exceptional performance, the Hydraulic Filter Mesh is also designed to be user-friendly. It features a hassle-free installation process, allowing for quick and easy replacement. Its compact size and lightweight nature make it convenient to handle and transport. These user-friendly characteristics contribute to the overall efficiency and effectiveness of the hydraulic system.The company behind the Hydraulic Filter Mesh has been a leader in the industry for several years. With a commitment to innovation and quality, they have continuously developed cutting-edge filtration solutions for various applications. Their extensive experience in the field, combined with state-of-the-art manufacturing facilities, ensures the production of superior products that meet the highest industry standards.To further ensure the reliability and performance of their products, the company conducts rigorous testing and quality control procedures. Each Hydraulic Filter Mesh undergoes thorough inspections and examinations to verify its functionality and effectiveness. This dedication to quality reassures customers that they are investing in a product that will deliver optimal results and value for their money.Moreover, the company maintains a strong focus on customer satisfaction. They provide excellent customer support, assisting users with any inquiries or issues they may encounter. By building long-lasting relationships with their clients, the company has earned a solid reputation and a loyal customer base.In conclusion, the Hydraulic Filter Mesh is a high-quality and reliable filtration solution for hydraulic systems. Its exceptional filtering capability, efficiency, durability, and user-friendly characteristics make it a preferred choice for industries relying on hydraulic systems. Manufacturered by a renowned company with a commitment to excellence, the Hydraulic Filter Mesh ensures optimal performance and peace of mind for its users.

High-Quality and Durable 4x8 Metal Mesh Sheets: Perfect for Various Applications

article:Metal Mesh Sheets have become increasingly popular in construction and industrial projects due to their versatility, durability, and strength. Most commonly used in the construction of fences, gates, and cages, these mesh sheets are also utilized in filtration systems and architectural designs. One company that has made their mark in the industry with their high-quality 4x8 Metal Mesh Sheets is [company name], a leading manufacturer and distributor of industrial materials.With over [number] years of experience in the industry, [company name] has established a reputation for providing the highest quality products and exceptional customer service. Their 4x8 Metal Mesh Sheets, in particular, are a perfect example of the company's commitment to excellence. These sheets are made from high-quality steel wire that is woven together to create a sturdy and reliable mesh that can withstand even the toughest of conditions. The sheets are available in a variety of mesh sizes and wire thicknesses, making them suitable for a wide range of applications.One of the main advantages of [company name]'s 4x8 Metal Mesh Sheets is their durability. The sheets are resistant to corrosion, rust, and general wear and tear, making them ideal for use in outdoor applications. Additionally, the mesh has a high strength-to-weight ratio, which means that it is incredibly strong and able to hold up under pressure while remaining lightweight and easy to handle.Another advantage of these metal mesh sheets is their versatility. They can be easily cut, shaped, and welded to fit specific project requirements, making them suitable for a wide range of projects. Whether it's creating an ornamental gate or screening for a filtration system, the 4x8 Metal Mesh Sheets from [company name] can be customized to meet specific project needs.Furthermore, [company name] is committed to providing their customers with exceptional levels of service and support. From initial inquiry to post-purchase follow-up, their team of experts is always on hand to offer guidance and advice. Additionally, they offer fast and efficient shipping, ensuring that customers receive their orders on time and in perfect condition.In conclusion, [company name]'s 4x8 Metal Mesh Sheets are a top-quality product that exemplifies the company's commitment to excellence. With their durability, versatility, and exceptional customer service, it's no wonder that they have become a top choice for architects, engineers, and contractors for a wide range of industrial and construction projects. Whether you are looking for a high strength metal mesh sheet for a fencing project, or a specialized filtration system, [company name] has got you covered.