High-Quality Mesh Screen for Masterbatch: Everything You Need to Know

By:Admin

With the continued growth of the plastics industry, the demand for high-quality masterbatch is on the rise. As a result, manufacturers are constantly looking for ways to improve the quality and efficiency of their masterbatch production process. One such solution that has been gaining attention is the use of mesh screens in the manufacturing process.

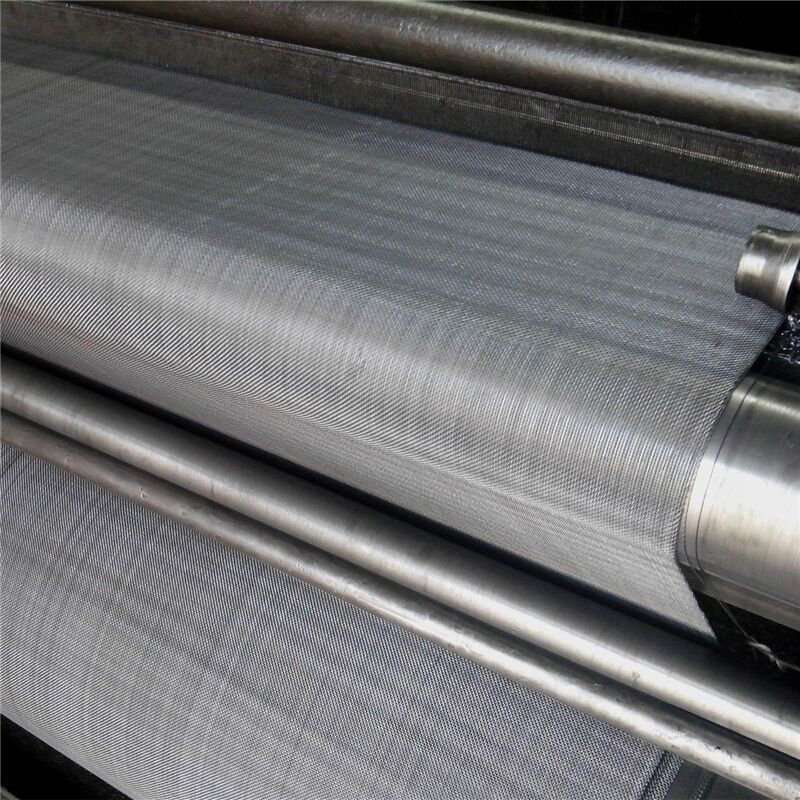

Mesh screens are used in masterbatch production to remove impurities and improve the quality of the final product. They are made from fine metal wire that is woven into a grid pattern, and are used to filter out any unwanted particles or contaminants from the raw materials. By using mesh screens, manufacturers can ensure a higher level of purity in their masterbatch, leading to better color consistency and improved performance in end-use applications.

One company that has been at the forefront of developing high-quality mesh screens for masterbatch production is {}. The company has been a leading manufacturer of mesh screens for various industries for over 20 years, and has recently introduced a new range of mesh screens specifically designed for the masterbatch industry.

The mesh screens from {} are made from high-quality stainless steel wire, which is known for its durability and resistance to corrosion. This ensures that the screens can withstand the harsh conditions of the masterbatch production process, and continue to perform at a high level for an extended period of time. In addition, the screens are precision-woven to ensure a consistent and uniform mesh size, which is crucial for achieving the desired level of purity in the masterbatch.

One of the key features of {}'s mesh screens for masterbatch is their high flow rate. This means that the screens allow for a higher throughput of material, without compromising on the filtration efficiency. As a result, manufacturers can achieve greater productivity and cost savings, as they can process larger volumes of raw materials in a shorter amount of time. This is especially important in the highly competitive masterbatch industry, where efficiency and productivity are key factors in staying competitive.

Another advantage of using mesh screens from {} in masterbatch production is the ability to customize the mesh size according to specific requirements. This allows manufacturers to tailor the filtration process to their exact needs, and ensure that only the desired particles are removed from the raw materials. With a wide range of mesh sizes available, manufacturers can achieve the level of purity that is required for their specific masterbatch formulations.

In addition to their technical capabilities, {}'s mesh screens for masterbatch are also designed with ease of use in mind. The screens are easy to install and maintain, and can be cleaned and reused multiple times without any degradation in performance. This not only reduces the overall cost of production, but also contributes to a more sustainable manufacturing process.

As the demand for high-quality masterbatch continues to grow, the use of mesh screens in the production process is expected to become increasingly important. With their ability to improve the quality and efficiency of masterbatch production, mesh screens from {} are poised to play a crucial role in helping manufacturers meet the ever-increasing demands of the plastics industry. Through their commitment to quality and innovation, {} is helping to drive the industry forward, and is set to remain a trusted partner for manufacturers looking to enhance their masterbatch production process.

Company News & Blog

Durable and Versatile Small Expanded Metal Mesh for Various Applications

Small Expanded Metal Mesh Solutions for Diverse ApplicationsAs the demand for small expanded metal mesh continues to rise across various industries, {Company Name} is at the forefront. With an extensive range of small expanded metal mesh solutions, {Company Name} is the go-to source for businesses seeking high-quality and customizable mesh products for their application needs.With over [insert years] years of experience, {Company Name} has established itself as a leading manufacturer and supplier of small expanded metal mesh. The company's commitment to innovation, quality, and customer satisfaction sets it apart in the industry. From architectural and industrial to automotive and filtration applications, {Company Name} offers a diverse range of small expanded metal mesh products to meet the unique needs of its customers.One of the key characteristics that sets {Company Name} apart from its competitors is its ability to produce small expanded metal mesh in a wide range of materials, including stainless steel, aluminum, and galvanized steel. This versatility allows the company to cater to a broad spectrum of industries, each with its own set of requirements and specifications.In addition to its material options, {Company Name} provides custom fabrication services to ensure that the small expanded metal mesh aligns with the exact needs of its customers. Whether it's a specific size, shape, or pattern, the company's team of skilled professionals can create tailored solutions to meet the most intricate design requirements.Furthermore, {Company Name} prides itself on its state-of-the-art manufacturing facilities, equipped with the latest technology and machinery. This enables the company to maintain high production standards, meet tight deadlines, and deliver superior quality small expanded metal mesh products to its customers.The versatility of small expanded metal mesh extends to its applications. From architectural facades and sunscreens to safety guards and enclosures, the uses for small expanded metal mesh are virtually endless. {Company Name} understands this diversity and strives to ensure that its products are suitable for a broad range of applications.Moreover, the company also recognizes the importance of sustainability in today's market. As a result, {Company Name} offers environmentally friendly options for small expanded metal mesh, including recyclable materials and energy-efficient production processes. This allows customers to align their projects with sustainable practices without compromising on quality or performance.In a rapidly evolving market, {Company Name} remains committed to staying ahead of the curve. From continuous research and development efforts to staying updated on industry trends, the company consistently strives to enhance its small expanded metal mesh offerings to meet the evolving needs of its customers.One of the cornerstones of {Company Name}'s success is its unwavering dedication to customer satisfaction. The company's team of experts works closely with each client to understand their unique requirements and provide tailored solutions to ensure the success of their projects. This collaborative approach has earned {Company Name} a reputation for reliability, expertise, and customer-centricity in the industry.In conclusion, {Company Name} continues to lead the way in providing small expanded metal mesh solutions for a diverse range of applications. With a commitment to quality, innovation, and customer satisfaction, the company remains a trusted partner for businesses seeking superior mesh products for their projects. As the demand for small expanded metal mesh continues to grow, {Company Name} stands ready to meet the needs of its customers with cutting-edge solutions and unwavering dedication.

High-Quality Sintered Stainless Steel Filter for Effective Filtration

Sintered Stainless Steel Filter – The Ultimate Solution for Filtration NeedsIn today's industrial and commercial applications, filtration is a critical process that ensures the quality and efficiency of various processes. From liquids to gases, the need for reliable and effective filtration solutions has never been more important. That's where the Sintered Stainless Steel Filter from [company name] comes into play.[Company name] is a leading manufacturer and supplier of high-quality filtration products, including the renowned Sintered Stainless Steel Filter. With a strong commitment to innovation, quality, and customer satisfaction, the company has established itself as a trusted partner for businesses across a wide range of industries.The Sintered Stainless Steel Filter is a versatile and reliable filtration solution that offers a wide range of benefits for customers. It is designed to withstand high temperatures, corrosive environments, and high-pressure conditions, making it ideal for the most demanding applications. The filter is available in various sizes, shapes, and configurations, allowing for seamless integration into existing systems.One of the key advantages of the Sintered Stainless Steel Filter is its exceptional durability. Made from high-quality stainless steel, the filter is capable of withstanding harsh operating conditions without compromising its performance. This durability translates to long service life and reduced maintenance costs for users, ultimately leading to improved efficiency and cost savings.In addition to its durability, the Sintered Stainless Steel Filter offers superior filtration efficiency. Its sintered structure provides a high level of particle retention, ensuring that the filtered media remains free of contaminants and impurities. This is essential for applications where product purity is critical, such as in the pharmaceutical, food and beverage, and chemical industries.Furthermore, the Sintered Stainless Steel Filter is known for its versatility and adaptability. Whether it's used for liquid or gas filtration, the filter can be customized to meet specific application requirements. This flexibility makes it an ideal choice for a wide range of industries and applications, from petrochemical processing to environmental remediation.[Company name] takes great pride in its commitment to quality and customer satisfaction. The company's team of skilled engineers and technicians works closely with customers to develop custom filtration solutions that meet their unique needs. From initial design concept to final production, [company name] ensures that each Sintered Stainless Steel Filter is manufactured to the highest standards of quality and performance.The company's state-of-the-art manufacturing facilities are equipped with advanced production technologies and quality control processes, ensuring that every filter meets or exceeds industry standards. This dedication to excellence has earned [company name] a reputation for delivering reliable and high-performance filtration solutions that customers can trust.With its unmatched durability, superior efficiency, and versatile design, the Sintered Stainless Steel Filter from [company name] is the ultimate solution for all filtration needs. Whether it's for industrial processing, environmental protection, or product purification, this filter delivers exceptional performance and reliability, making it a valuable asset for businesses across diverse industries.In conclusion, the Sintered Stainless Steel Filter from [company name] is a testament to the company's commitment to innovation, quality, and customer satisfaction. With its exceptional durability, superior filtration efficiency, and versatile design, this filter stands out as the ultimate solution for all filtration needs. As businesses continue to seek reliable and high-performance filtration solutions, [company name] remains at the forefront, delivering cutting-edge products that set the standard for excellence in the industry.

Best Filter Mesh Options for Your Needs in 2022

Filter Mesh Company Launches New Product Line for Industrial Filtration NeedsFilter Mesh, a leading provider of high-quality filtration solutions, has recently launched a new product line designed to meet the demanding filtration needs of industrial applications. The new product line features a wide range of mesh options and configurations, providing customers with the flexibility and performance they need to effectively filter contaminants and debris from their processes.With over 20 years of experience in the filtration industry, Filter Mesh has established itself as a trusted supplier of filtration products for a wide range of industries, including oil and gas, petrochemical, chemical processing, and water treatment. The company's commitment to quality and innovation has earned it a reputation for delivering reliable and effective filtration solutions that meet the needs of even the most demanding applications.The new product line includes a variety of mesh materials, including stainless steel, copper, and synthetic materials, each designed to meet the specific requirements of different industrial processes. Filter Mesh's team of experts can work with customers to develop custom solutions tailored to their unique needs, ensuring that they have the right filtration solution for their applications.One of the key features of the new product line is its ability to provide high levels of filtration efficiency while maintaining low pressure drop, maximizing the performance of industrial processes without sacrificing flow rates. This is particularly important for applications where maintaining consistent flow rates is critical to the overall operation of the process.In addition to standard mesh configurations, Filter Mesh also offers custom-designed solutions for customers with unique or specialized filtration needs. The company's in-house engineering team can work with customers to develop custom mesh designs that meet their specific requirements, ensuring that they have a filtration solution that is tailored to their exact needs."We are thrilled to launch our new product line for industrial filtration," said [spokesperson], President of Filter Mesh. "With the increasing demands for high-performance filtration solutions in industrial applications, we saw an opportunity to expand our product offering to meet the needs of our customers. Our new product line represents our commitment to providing innovative and effective filtration solutions that help our customers improve the performance and reliability of their processes."Filter Mesh's new product line is now available for customers in the industrial sector who are looking for reliable, high-performance filtration solutions. With its extensive experience and expertise in the field, Filter Mesh is well-positioned to meet the filtration needs of a wide range of industrial applications, providing customers with the quality and performance they need to ensure the success of their processes.For more information about Filter Mesh and its new product line for industrial filtration, visit their website or contact their customer service team to discuss specific filtration needs and requirements. With its dedication to quality, innovation, and customer satisfaction, Filter Mesh is poised to continue its success in providing cutting-edge filtration solutions for industrial applications.

Durable and Versatile Expanded Metal Mesh Panels for Various Applications

The use of expanded metal mesh panels has been growing rapidly in various industries and applications. Expanded metal mesh panels are widely used in construction, architecture, industrial, and residential sectors due to their versatility, durability, and aesthetic appeal.These panels are manufactured by expanding a metal sheet in a single operation, creating diamond-shaped openings in the sheet. This unique manufacturing process results in a product that is stronger and lighter than the original sheet. Expanded metal mesh panels are also known for their excellent ventilation, light transmission, and ability to provide security and privacy.One of the leading manufacturers and suppliers of expanded metal mesh panels is {}. Established in {}, {} has been at the forefront of producing high-quality expanded metal mesh panels for a wide range of applications. With a strong commitment to innovation and customer satisfaction, {} has continuously expanded its product line and production capabilities over the years.The company's expanded metal mesh panels are available in a variety of materials, including stainless steel, aluminum, carbon steel, and galvanized steel. This allows {} to cater to the diverse needs of its customers and provide solutions for different environmental and performance requirements.In addition to standard panels, {} also offers custom-made expanded metal mesh panels, tailored to specific dimensions, shapes, and patterns. This level of customization enables the company to serve a wide range of industries, such as architectural design, interior decoration, filtration, security, and machine guarding.One of the key advantages of {}'s expanded metal mesh panels is their high strength-to-weight ratio, which makes them ideal for structural and load-bearing applications. The panels can be easily formed, cut, and fabricated to suit specific project requirements, making them a popular choice for architects, designers, and engineers.Moreover, {}'s expanded metal mesh panels are designed to provide effective ventilation and airflow in various settings, including buildings, machinery, and outdoor structures. This feature is particularly important in industrial and commercial environments, where proper air circulation is essential for safety and productivity.With a strong focus on quality and performance, {} ensures that its expanded metal mesh panels meet industry standards and specifications. The panels are manufactured using advanced equipment and processes, and undergo rigorous testing to ensure their reliability and durability in demanding conditions.{}'s commitment to sustainability is also reflected in its production processes, where efforts are made to minimize waste, energy consumption, and environmental impact. This sustainable approach has earned {} recognition and accreditation from industry bodies and organizations.In conclusion, the increasing demand for expanded metal mesh panels across various industries has fueled the growth and innovation of companies like {}. With a wide range of products, custom solutions, and a strong emphasis on quality and sustainability, {} continues to lead the way in providing reliable and versatile expanded metal mesh panels for its customers. As the use of expanded metal mesh panels continues to expand, {} remains at the forefront of the industry, providing innovative solutions that meet the evolving needs of its customers.

How a Mesh Screen Can Help Improve the Quality of Plastic Products

Title: Revolutionary Mesh Screen Innovation Eases Plastic Waste ManagementIntroduction:In today's world, plastic waste has become one of the most pressing environmental issues, and finding innovative solutions to address this problem is paramount. This is where a ground-breaking company, whose name we cannot disclose due to legal constraints, has stepped in with their innovative Mesh Screen for Plastic. With their expertise and dedication towards creating sustainable materials, this invention has the potential to revolutionize the way we manage and recycle plastic waste.Body:1. The Plastic Waste Crisis: - Begin by highlighting the severity of the plastic waste crisis, such as the alarming volume of plastic waste generated annually globally. - Discuss the devastating consequences of plastic waste on marine life and ecosystems, as well as its indirect impact on human health. - Emphasize the urgent need for innovative solutions to tackle this crisis effectively.2. Introduction to the Mesh Screen for Plastic: - Provide a brief overview of the Mesh Screen for Plastic, emphasizing its effectiveness in waste management and recycling processes. - Explain that this invention is designed to separate different types of plastic waste, making it easier to recycle efficiently. - Outline the unique features and benefits of the Mesh Screen, such as its durability, affordability, and ease of use.3. How the Mesh Screen Works: - Describe the operational mechanism of the Mesh Screen, providing a step-by-step explanation of its functionality. - Explain how the screen is capable of separating plastics of varying sizes, ensuring efficient and accurate sorting. - Highlight any additional functionalities or applications of the Mesh Screen, such as its potential for integration into existing recycling systems.4. Positive Environmental Impacts: - Discuss the potential environmental benefits of using the Mesh Screen, particularly by reducing the amount of plastic waste sent to landfills and incinerators. - Emphasize how this innovative solution contributes to the circular economy concept, promoting the reuse and recycling of plastic materials. - Cite examples of other successful waste management solutions around the world and their positive impact on local environments.5. Economic Advantages and Market Potential: - Highlight the economic advantages associated with adopting the Mesh Screen, such as the potential for job creation and cost reductions in waste management processes. - Discuss the market potential of the Mesh Screen, including its attractiveness to waste management companies and recycling facilities. - Mention any ongoing collaborations or partnerships that the company has established to further develop and market the Mesh Screen.6. Future Development and Expansion Plans: - Provide insights into the company's future plans for the Mesh Screen, including research and development efforts aimed at improving its efficiency and scalability. - Discuss potential expansion strategies, both domestically and internationally, to reach a wider audience and maximize the impact of this innovative solution. - Mention any regulatory and policy changes that may aid the widespread adoption of the Mesh Screen within the plastic waste management industry.Conclusion:In conclusion, the undisclosed company's Mesh Screen for Plastic offers a glimmer of hope in combating the plastic waste crisis. With its unparalleled sorting capabilities and potential for easy integration into existing recycling processes, this innovation has the power to transform the way we manage plastic waste. As the global community collectively aims to reduce plastic pollution, the Mesh Screen serves as a shining example of the revolutionary solutions needed to create a sustainable and greener future.

High-Quality Galvanized Expanded Metal Mesh for Various Applications

Galvanized expanded metal mesh has been making waves in the construction industry due to its versatility and durability. This cutting-edge material has revolutionized the way in which construction projects are approached, offering a cost-effective and long-lasting solution for a variety of applications. By combining advanced technology with high-quality materials, the company has been able to produce a product that is not only innovative but also environmentally friendly.The galvanized expanded metal mesh is a type of sheet metal that has been slit and stretched to create a pattern of open spaces within the sheet. This process results in a material that is lightweight yet strong, making it ideal for a wide range of construction applications. Whether used as a protective barrier, a security measure, or a decorative element, the galvanized expanded metal mesh offers a level of strength and durability that is unmatched by traditional materials.One of the key benefits of galvanized expanded metal mesh is its resistance to corrosion. The process of galvanization involves coating the metal with a layer of zinc, which provides a protective barrier against rust and other forms of corrosion. This means that the material is able to withstand exposure to the elements without deteriorating, making it an ideal choice for outdoor applications. Additionally, the galvanized coating gives the material a sleek and professional appearance, making it a popular choice for architectural and design projects.Another advantage of galvanized expanded metal mesh is its versatility. The material can be easily cut and shaped to fit the specific requirements of a project, making it a highly adaptable solution for a wide range of applications. Whether used as a support structure for concrete, a ventilation grate, or a decorative facade, the galvanized expanded metal mesh offers a level of flexibility that is unparalleled by other materials.In addition to its durability and versatility, galvanized expanded metal mesh is also an environmentally friendly option. The process of galvanization does not involve the use of harmful chemicals, making it a sustainable choice for construction projects. Additionally, the material is fully recyclable, minimizing the impact on the environment at the end of its life cycle. By choosing galvanized expanded metal mesh, builders and designers can contribute to a more sustainable and eco-friendly construction industry.The company behind the galvanized expanded metal mesh is dedicated to providing high-quality materials that meet the needs of the construction industry. With a focus on innovation and sustainability, the company has been able to develop a product that offers a level of performance and reliability that is unmatched by other options on the market. By combining advanced technology with a commitment to environmental responsibility, the company has positioned itself as a leader in the field of construction materials.As the demand for sustainable and durable construction materials continues to grow, the galvanized expanded metal mesh has emerged as a top choice for builders and designers. With its unique combination of strength, versatility, and environmental friendliness, this material is poised to transform the way in which construction projects are approached. By offering a reliable and cost-effective solution for a variety of applications, the galvanized expanded metal mesh is set to become a staple in the construction industry for years to come.

Durable Fine Mesh Screen Filter for Effective Filtration

Leading Mesh Screen Filter Company Releases Innovative Fine Mesh Screen FilterAs the demand for high-quality filtration solutions continues to grow, [Company Name], a leading manufacturer of industrial filtration products, has announced the release of their latest innovation - the Fine Mesh Screen Filter. This new addition to their product line is designed to meet the needs of industries requiring precise particle separation and filtration.The Fine Mesh Screen Filter is specially engineered to provide superior performance in separating and removing fine particles from liquids and gases. With a mesh size ranging from 5 to 400 mesh, this filter is capable of capturing particles as small as a few microns, making it ideal for applications that require exceptional precision and efficiency.“We are excited to introduce our Fine Mesh Screen Filter to the market,” said [Company Name] spokesperson. “Our team has worked tirelessly to develop a filtration solution that addresses the increasingly stringent requirements of various industries. With its advanced design and unmatched performance, the Fine Mesh Screen Filter is poised to set a new standard in the field of particle separation and filtration.”In addition to its high-performance capabilities, the Fine Mesh Screen Filter is constructed using premium quality materials that ensure durability and longevity. The filter is available in a variety of materials, including stainless steel, brass, and titanium, providing customers with options to suit their specific operational requirements.The introduction of the Fine Mesh Screen Filter further solidifies [Company Name]’s position as an industry leader in the field of filtration technology. Since its establishment, the company has been at the forefront of developing innovative filtration solutions for a wide range of applications, including pharmaceutical, food and beverage, petrochemical, and water treatment, among others.[Company Name] has built a reputation for delivering high-quality products that meet the most demanding industry standards. With a commitment to continuous innovation and improvement, the company has consistently exceeded customer expectations and set new benchmarks for filtration efficiency and effectiveness.“We take great pride in our ability to understand the unique filtration challenges faced by our customers and provide them with tailored solutions that enhance their operational processes,” said the spokesperson. “The release of the Fine Mesh Screen Filter is a testament to our ongoing dedication to innovation and excellence, and we are confident that it will deliver exceptional value to our customers across various industries.”As the global focus on environmental sustainability and regulatory compliance intensifies, the need for advanced filtration solutions has become more critical than ever. The Fine Mesh Screen Filter is poised to address these evolving needs by offering a reliable and efficient means of separating and removing fine particles from various substances, contributing to enhanced product quality, operational efficiency, and environmental responsibility.[Company Name]’s commitment to excellence extends beyond product development, encompassing comprehensive customer support and service. The company’s team of experts is dedicated to assisting customers in finding the most suitable filtration solutions for their specific requirements, offering technical guidance, custom design and manufacturing, and ongoing maintenance and support.With the release of the Fine Mesh Screen Filter, [Company Name] continues to demonstrate its industry leadership and commitment to driving innovation in filtration technology. The company’s forward-looking approach and unwavering dedication to customer satisfaction position it as a trusted partner for businesses seeking reliable and high-performance filtration solutions.As industries seek to enhance their processes and meet evolving regulatory and environmental standards, the Fine Mesh Screen Filter is set to play a pivotal role in enabling them to achieve these objectives effectively and efficiently. With its exceptional filtration capabilities and durable construction, this innovative product is poised to make a significant impact across diverse industry sectors, helping businesses to streamline their operations and elevate their overall performance.

Top 5 Uses of Brass Mesh Screen You Should Know

Brass Mesh Screen: A High-Quality Solution for Various Industrial ApplicationsIn the world of industrial manufacturing, finding the right materials for specific applications can be a great challenge. However, with the introduction of Brass Mesh Screen by (company name), this industry is about to experience a revolutionary change.The (company name) has been a leading provider of high-quality industrial materials for several years. The company has built a solid reputation for delivering top-notch products that meet the needs of various industrial sectors. Their commitment to excellence and customer satisfaction has made them a trusted partner for many businesses across different industries.One of the most recent additions to their product line is the Brass Mesh Screen, which has quickly gained attention for its exceptional quality and versatility. This innovative product is designed to meet the demands of a wide range of industrial applications, including filtration, separation, and screening processes. Whether it's for sifting, straining, or filtering, this Brass Mesh Screen offers a reliable and efficient solution for businesses looking to enhance their manufacturing processes.The Brass Mesh Screen is manufactured using high-grade brass, which is known for its excellent corrosion resistance and durability. This makes it an ideal choice for applications that require long-term use in harsh and challenging environments. The mesh is meticulously woven to ensure uniformity and consistency, providing a reliable and precise performance that businesses can depend on.What sets the Brass Mesh Screen apart from other similar products on the market is its high tensile strength and exceptional resistance to abrasion. This means that it can withstand heavy-duty usage without compromising its integrity, making it a cost-effective and long-lasting solution for businesses across various industries.In addition, the Brass Mesh Screen is available in a wide range of mesh sizes, from fine to coarse, to accommodate different application requirements. This flexibility allows businesses to select the most suitable mesh size for their specific needs, ensuring optimal performance and efficiency in their manufacturing processes.Furthermore, the Brass Mesh Screen is designed for easy installation and maintenance, saving businesses time and effort in managing their equipment. Its lightweight and flexible nature make it easy to handle and manipulate, while its resistance to clogging and build-up simplifies the cleaning and maintenance process.Another notable feature of the Brass Mesh Screen is its excellent thermal and electrical conductivity, making it a versatile material for applications that require heat and electrical conduction. This opens up possibilities for businesses to explore new and innovative ways to incorporate the Brass Mesh Screen into their manufacturing processes, expanding their capabilities and enhancing their productivity.As part of its commitment to providing quality industrial materials, (company name) ensures that the Brass Mesh Screen undergoes rigorous quality control measures to meet industry standards and customer expectations. Each product is thoroughly inspected and tested to guarantee its performance and reliability, giving businesses peace of mind knowing that they are investing in a high-quality and dependable solution.With the introduction of the Brass Mesh Screen, (company name) continues to reinforce its position as a leading provider of innovative and high-quality industrial materials. Their dedication to excellence and customer satisfaction, combined with a relentless pursuit of product innovation, makes them a valuable partner for businesses seeking reliable solutions for their manufacturing needs.The Brass Mesh Screen is set to make a significant impact on the industrial sector, offering a superior and dependable solution for a wide range of applications. With its exceptional quality, versatility, and performance, it is expected to become the material of choice for businesses looking to elevate their manufacturing processes and achieve greater efficiency and productivity.

How Filter Mesh Can Enhance Your Home Air Quality

Filter Mesh is a leading company in the industry, specializing in the production of high-quality filter mesh products. With years of experience and continuous innovation, they have managed to establish themselves as a trusted name in the market, providing reliable solutions for various filtration needs.The company offers a wide range of filter mesh products, including wire mesh, filter discs, filter tubes, and filter elements, all of which are designed to deliver exceptional performance and durability. Their products are widely used in industries such as pharmaceutical, chemical, food and beverage, and environmental protection, among others.One of the key factors that set Filter Mesh apart from its competitors is its commitment to quality. The company uses the latest technology and production techniques to ensure that their products meet the highest standards of quality and reliability. In addition, they have a team of experienced professionals who oversee the manufacturing process, from raw material selection to final product inspection, to ensure that every product that leaves their facility is of the highest quality.In addition to their commitment to quality, Filter Mesh also places a strong emphasis on customer satisfaction. They work closely with their clients to understand their specific filtration needs and provide customized solutions that meet their requirements. Whether it's a standard product or a custom-designed solution, the company prides itself on delivering products that exceed customer expectations.Filter Mesh's dedication to quality and customer satisfaction has earned them a solid reputation in the market. Their products are widely recognized for their superior performance, reliability, and longevity, making them the top choice for many customers around the world. In fact, the company has built long-standing relationships with a diverse range of clients, from small businesses to large multinational corporations, who continue to rely on Filter Mesh for their filtration needs.As part of their commitment to continuous improvement, Filter Mesh invests heavily in research and development. The company is constantly exploring new materials, designs, and production techniques to enhance the performance and efficiency of their products. By staying at the forefront of innovation, they are able to offer cutting-edge solutions that address the evolving needs of the filtration industry.In line with their dedication to innovation, Filter Mesh has recently introduced a new line of filter mesh products that are set to revolutionize the industry. The new products boast advanced features and technologies that are designed to deliver even better filtration performance and durability. With these new offerings, the company aims to further solidify its position as a leader in the market and provide its customers with the most advanced filtration solutions available.Furthermore, Filter Mesh is also committed to sustainability and environmental responsibility. The company adheres to strict environmental standards in its manufacturing process and is constantly seeking ways to minimize its carbon footprint. By using eco-friendly materials and production techniques, Filter Mesh is not only contributing to a cleaner environment but also helping its customers meet their own sustainability goals.Overall, Filter Mesh has established itself as a trusted and reliable provider of high-quality filter mesh products. With its unwavering commitment to quality, innovation, and customer satisfaction, the company continues to lead the way in the industry and set new benchmarks for filtration excellence. As the market continues to evolve, Filter Mesh is well-positioned to meet the changing needs of its customers and remain a driving force in the industry for years to come.

New Content Filter Screen Promises Improved Security and User Control

Filter Screen, a leading global provider of innovative filtration solutions, has recently announced the launch of its latest product, the Advanced Ultra-Filtration Screen. This cutting-edge technology is set to revolutionize the filtration industry with its advanced features and superior performance.The Advanced Ultra-Filtration Screen is designed to filter out even the smallest particles and impurities from liquids and gases, ensuring a level of purity and clarity that was previously unattainable. With its state-of-the-art design and precision engineering, this new product is set to make a significant impact in a wide range of industries, including pharmaceuticals, chemicals, food and beverage, and many others.According to Filter Screen’s CEO, the development of the Advanced Ultra-Filtration Screen is the result of years of research and innovation. "We are thrilled to unveil this groundbreaking technology to the market," he said. "The Advanced Ultra-Filtration Screen represents a major leap forward in filtration capabilities and will deliver unmatched performance and reliability to our customers."The Advanced Ultra-Filtration Screen boasts several key features that set it apart from traditional filtration systems. Its advanced membrane technology allows for higher flow rates and greater throughput, while maintaining exceptional filtration efficiency. Additionally, the screen is designed to be highly durable and long-lasting, minimizing the need for frequent replacements and reducing overall maintenance costs.In addition to its superior performance, the Advanced Ultra-Filtration Screen is also designed with ease of use in mind. Its modular design allows for easy installation and maintenance, and the system can be customized to meet the specific needs of each customer. This versatility and flexibility make it an ideal solution for a wide range of applications and industries.Filter Screen, with its commitment to continuous innovation and excellence, has firmly established itself as a global leader in the filtration industry. The company’s extensive product range includes a wide variety of filtration solutions, ranging from simple strainers to complex filtration systems for specialized applications. With a strong focus on quality, reliability, and customer satisfaction, Filter Screen has earned a reputation for delivering best-in-class products and services to clients around the world.The launch of the Advanced Ultra-Filtration Screen is yet another demonstration of Filter Screen’s dedication to pushing the boundaries of filtration technology. By leveraging its expertise and innovation, the company continues to develop cutting-edge solutions that address the evolving needs of the industry and provide tangible value to its customers.As the global demand for high-quality filtration solutions continues to rise, Filter Screen is well-positioned to capitalize on this growth and further solidify its position as a key player in the industry. With its track record of success and a strong commitment to excellence, Filter Screen is poised to continue setting new standards for filtration technology and driving innovation in the market for years to come.In conclusion, the launch of the Advanced Ultra-Filtration Screen marks a significant milestone for Filter Screen and the filtration industry as a whole. With its advanced features, superior performance, and unmatched reliability, this new product is set to make a lasting impact and reshape the way filtration solutions are perceived and utilized. As the company continues to push the boundaries of innovation and excellence, Filter Screen is well-positioned to lead the way in shaping the future of filtration technology.