Wire Knitted Mesh: A Guide to Nickel Wire Knitted Mesh

By:Admin

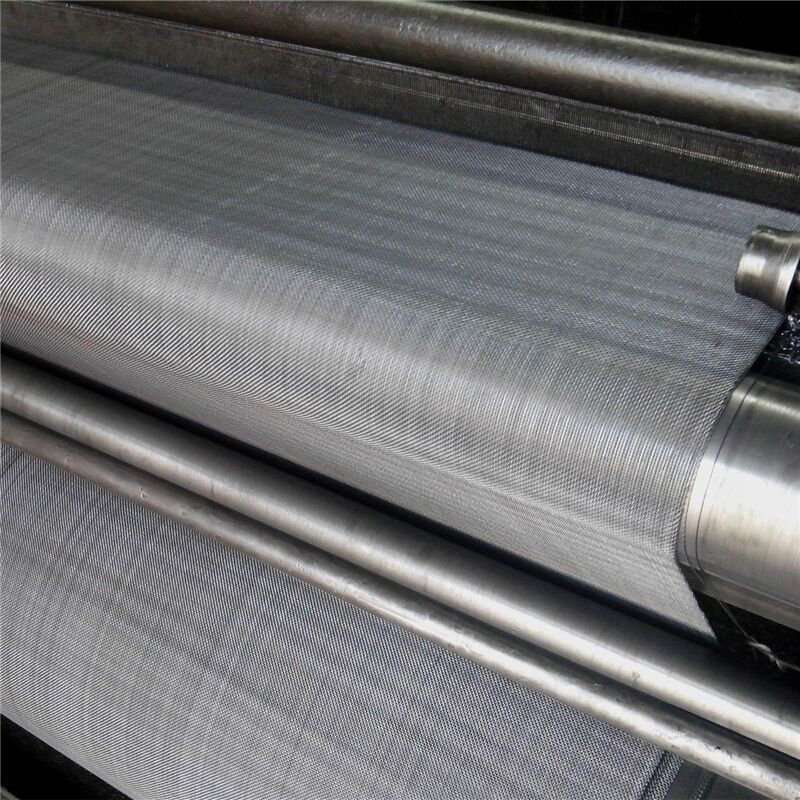

Nickel wire knitted mesh is a type of wire mesh that is made from high-quality, corrosion-resistant nickel wire. It is commonly used in a variety of industries, including aerospace, automotive, chemical, and petrochemical. This type of mesh is valued for its excellent resistance to high temperatures, corrosion, and oxidation, making it a popular choice for demanding applications.

The newly introduced Nickel Wire Knitted Mesh from [Company Name] is manufactured using state-of-the-art weaving technology, ensuring that the mesh is of the highest quality and meets the stringent requirements of their customers. The mesh is available in a range of sizes and configurations, making it suitable for a wide variety of applications.

[Company Name] is known for its commitment to quality and excellence, and the introduction of Nickel Wire Knitted Mesh is a testament to their dedication to providing innovative solutions to their customers. With years of experience in the field of wire knitted mesh manufacturing, the company is able to leverage their expertise and knowledge to produce products that meet the highest industry standards.

In addition to Nickel Wire Knitted Mesh, [Company Name] offers a wide range of wire mesh products, including stainless steel wire mesh, copper wire mesh, and galvanized wire mesh. Their products are used in a variety of applications, including filtration, separation, and reinforcement, and are valued for their durability, reliability, and performance.

[Company Name] is committed to providing exceptional customer service, and their team of experts is available to assist customers in finding the right solution for their specific needs. With a focus on innovation and continuous improvement, the company is dedicated to staying ahead of the curve and offering products that meet the evolving demands of the market.

The introduction of Nickel Wire Knitted Mesh is an important milestone for [Company Name], and the company is excited to offer customers a new, high-quality solution for their wire mesh needs. With their commitment to quality, excellence, and customer satisfaction, [Company Name] is well-positioned to continue to be a leader in the field of wire knitted mesh manufacturing.

In conclusion, the introduction of Nickel Wire Knitted Mesh by [Company Name] represents an exciting new development in the world of wire mesh manufacturing. With a focus on quality, innovation, and customer satisfaction, the company is well-equipped to meet the diverse needs of their customers and provide them with high-performance solutions for a wide range of applications. As [Company Name] continues to grow and expand their product line, they are poised to remain a leader in the industry and a trusted partner for their customers.

Company News & Blog

Discover the Benefits of Aluminum Wire Mesh Screens for Your Home

Title: Innovation in Aluminum Wire Mesh Screens Revolutionizes the IndustrySubtitle: Company Unveils Cutting-edge Aluminum Wire Mesh Screen for Enhanced Efficacy and DurabilityIntroduction:In a revolutionary development within the wire mesh industry, an undisclosed company is set to launch its latest innovation in the form of an aluminum wire mesh screen. This cutting-edge product is set to provide increased efficacy and durability, making it a game-changer for a multitude of applications. Leveraging their extensive expertise and commitment to innovation, this company aims to redefine the industry standards by offering a highly efficient, reliable, and long-lasting solution.Body:1. Background: Introduce the company's background and commitment to excellence in developing high-quality wire mesh products. Highlight their continuous efforts in research and development to meet the evolving needs of their customers.2. Introduction of the Aluminum Wire Mesh Screen: Present the unique features and capabilities of the aluminum wire mesh screen. Emphasize its critical role in various applications such as industrial filtration, insect screens, security fencing, and architectural design elements.3. Enhanced Efficacy: Discuss the advancements in the aluminum wire mesh screen that contribute to its increased effectiveness compared to conventional screens. Highlight the superior material properties, such as corrosion resistance, lightweight, and high tensile strength, which make it ideal for demanding industrial applications.4. Durability and Longevity: Emphasize the exceptional durability of the aluminum wire mesh screen, which ensures a prolonged lifespan, reducing maintenance costs over time. Discuss the screen's ability to withstand harsh weather conditions, UV radiation, and extreme temperatures, ensuring optimal performance and ensuring reliability.5. Versatility and Applications: Explore the wide range of applications for the aluminum wire mesh screen. Outline its use in industrial filtration systems, where it serves as a reliable barrier against debris and unwanted particles, ensuring the efficiency and longevity of machinery. Mention its applications in insect screens, offering a sturdy shield for residential and commercial properties while allowing optimal airflow and visibility.6. Security and Architectural Design: Highlight the role of aluminum wire mesh screens in security fencing systems. Discuss how the robust construction and closely woven mesh design provide enhanced security without compromising aesthetics. Showcase its potential for architectural designs, where it adds a modern touch to facades, balconies, and other structural elements.7. Environmental Considerations: Address the eco-friendly nature of aluminum wire mesh screens compared to alternative materials. Discuss how aluminum is a sustainable option due to its recyclability, low carbon footprint, and extended lifespan, contributing to a greener future.8. Conclusion: Summarize the impact of this innovative aluminum wire mesh screen on the wire mesh industry. Reinforce its benefits such as enhanced efficacy, durability, and versatility, making it a reliable choice for various applications. Highlight the company's commitment to innovation and customer satisfaction, setting the stage for future advancements in wire mesh technology.Note: While the content provided offers a framework for an 800-word news article, modifications and additions may be necessary to include the company's specific introduction and align with the provided brand information.

Replace Your Hydraulic Filter Mesh for Optimal Performance

Hydraulic Filter Mesh: Enhancing Efficiency and ReliabilityHydraulic systems play a crucial role in various industries, ensuring smooth operations and efficient performance. To maintain the optimal functionality of these systems, the use of high-quality hydraulic filters is essential. Among the most reliable and effective options available in the market is the Hydraulic Filter Mesh, which has gained significant recognition for its efficiency and reliability.The Hydraulic Filter Mesh, manufactured by a leading company in the industry, is designed to offer exceptional filtration performance in hydraulic systems. It is developed using advanced technology and high-quality materials to ensure durability and longevity. This innovative filter mesh is suitable for a wide range of applications, including automotive, industrial, and construction sectors.One of the key features that sets the Hydraulic Filter Mesh apart from other filters is its filtering capability. With a precise and intricate mesh design, it effectively captures and removes contaminants from hydraulic fluids, such as dirt, debris, and metal shavings. This ensures that the hydraulic system operates smoothly and prevents any damage to the components or machinery.Furthermore, the Hydraulic Filter Mesh offers a high level of efficiency and reliability. Its fine mesh structure enables the filtration of particles as small as a few microns, guaranteeing clean and debris-free hydraulic fluids. This enhances the overall performance of the system and reduces the risk of system failures or breakdowns.The durability of the Hydraulic Filter Mesh is another notable aspect that sets it apart. Constructed with robust materials, it remains functional even under extreme operating conditions, such as high pressure and temperature. This durability ensures a longer lifespan, reducing the need for frequent replacements and maintenance, thus saving both time and costs for the users.In addition to its exceptional performance, the Hydraulic Filter Mesh is also designed to be user-friendly. It features a hassle-free installation process, allowing for quick and easy replacement. Its compact size and lightweight nature make it convenient to handle and transport. These user-friendly characteristics contribute to the overall efficiency and effectiveness of the hydraulic system.The company behind the Hydraulic Filter Mesh has been a leader in the industry for several years. With a commitment to innovation and quality, they have continuously developed cutting-edge filtration solutions for various applications. Their extensive experience in the field, combined with state-of-the-art manufacturing facilities, ensures the production of superior products that meet the highest industry standards.To further ensure the reliability and performance of their products, the company conducts rigorous testing and quality control procedures. Each Hydraulic Filter Mesh undergoes thorough inspections and examinations to verify its functionality and effectiveness. This dedication to quality reassures customers that they are investing in a product that will deliver optimal results and value for their money.Moreover, the company maintains a strong focus on customer satisfaction. They provide excellent customer support, assisting users with any inquiries or issues they may encounter. By building long-lasting relationships with their clients, the company has earned a solid reputation and a loyal customer base.In conclusion, the Hydraulic Filter Mesh is a high-quality and reliable filtration solution for hydraulic systems. Its exceptional filtering capability, efficiency, durability, and user-friendly characteristics make it a preferred choice for industries relying on hydraulic systems. Manufacturered by a renowned company with a commitment to excellence, the Hydraulic Filter Mesh ensures optimal performance and peace of mind for its users.

Durable Wire Mesh Fencing for Heavy Duty Applications

As the demand for heavy-duty wire mesh fencing continues to rise, {Company Name} has emerged as a leader in the industry, providing high-quality fencing solutions for various commercial, industrial, and security applications. With a commitment to innovation, quality, and customer satisfaction, {Company Name} has set the standard for durable and reliable wire mesh fencing products.Established in {year}, {Company Name} has quickly grown to become a trusted name in the fencing industry. The company's state-of-the-art manufacturing facilities and advanced technology allow them to produce a wide range of wire mesh fencing products that meet the highest standards of quality and durability. From chain link fencing to welded wire mesh panels, {Company Name} offers a comprehensive range of products to suit the diverse needs of their customers.One of {Company Name}'s flagship products is their heavy-duty wire mesh fencing, which is designed to provide maximum security and protection in high-risk environments. Made from high-quality galvanized steel, the fencing is built to withstand harsh weather conditions, corrosion, and wear and tear, making it a reliable and long-lasting solution for perimeter security. Whether it's for a construction site, a government facility, or a commercial property, {Company Name}'s heavy-duty wire mesh fencing provides the peace of mind that comes with knowing that the property is secure and protected.In addition to its durability, {Company Name}'s heavy-duty wire mesh fencing is also highly customizable, allowing customers to choose from a range of wire thicknesses, mesh sizes, and panel dimensions to meet their specific security needs. Furthermore, the fencing can be powder coated in a variety of colors to match the aesthetic of the surrounding environment, making it a versatile and visually appealing option for any application.{Company Name} takes pride in its commitment to customer satisfaction, and their team of experienced professionals works closely with each client to assess their security needs and recommend the most suitable fencing solution. From design and production to installation and ongoing maintenance, {Company Name} provides a comprehensive and personalized service to ensure that their customers' security requirements are met with the highest level of expertise and attention to detail.As a company that prioritizes innovation and continuous improvement, {Company Name} invests heavily in research and development to stay ahead of the curve in the fencing industry. Their team of engineers and designers are constantly working on developing new and improved fencing solutions that incorporate the latest advancements in materials and manufacturing techniques, ensuring that {Company Name} remains at the forefront of the industry.With a strong track record of delivering exceptional products and services, {Company Name} has earned the trust and respect of clients across various industries. Their commitment to quality, reliability, and customer satisfaction has solidified their reputation as a leading provider of heavy-duty wire mesh fencing solutions, and they continue to set the bar high for excellence in the industry.In conclusion, {Company Name} is dedicated to providing innovative, high-quality, and customizable heavy-duty wire mesh fencing solutions to meet the security needs of their diverse customer base. With a focus on durability, reliability, and customer satisfaction, {Company Name} has established itself as a trusted leader in the fencing industry, and is well positioned to continue serving the security needs of clients for years to come.

Sintered Stainless Steel Filters: A Guide to their Benefits and Applications

Title: Innovative Sintered Stainless Steel Filter Revolutionizes Filtration TechnologyIntroduction:In today's modern world, filtration technology plays a crucial role in various industries, from healthcare and food processing to automotive and manufacturing. Recognizing the growing demand for advanced filtration systems, an innovative company aims to revolutionize the industry with their cutting-edge Sintered Stainless Steel Filter. By leveraging its superior capabilities and exceptional performance, this groundbreaking filter is set to transform numerous applications, ensuring higher efficiency, durability, and improved product quality.Background:(company name), a leader in filtration solutions, has gained an outstanding reputation for its commitment to innovation and engineering excellence. With a rich history of developing pioneering products, the company has once again raised the bar with its latest breakthrough in filtration technology – the Sintered Stainless Steel Filter.Description and Features:The Sintered Stainless Steel Filter is a highly advanced filtration solution that surpasses traditional filters in terms of efficiency and durability. Its key distinguishing feature lies in the sintering process, which involves compacting powdered stainless steel particles to form a solid, porous structure. This intricate network of interconnected pores acts as an effective barrier against impurities, allowing only clean fluids or gases to pass through.The following features contribute to the superiority of the Sintered Stainless Steel Filter:1. Unparalleled Durability: Constructed from high-quality stainless steel, this filter boasts exceptional resistance to corrosion, temperature extremes, and mechanical stress. It ensures durability, longevity, and consistent performance even in the harshest operating conditions.2. Superior Filtration Efficiency: The filter's intricate pore structure enables precise filtration, providing high removal efficiency for various sizes of particles or contaminants. Its precisely controlled pore sizes ensure optimal flow rates while capturing particles as small as a few microns.3. Wide Range of Applications: The Sintered Stainless Steel Filter finds extensive applications across diverse industries, including oil and gas, chemical processing, pharmaceuticals, food and beverage, water treatment, automotive, and aerospace. With its versatility, it addresses an array of filtration demands, from liquid clarification to gas purification.4. Easy Maintenance and Cleaning: Another advantage is its easy maintenance. The filter can be conveniently cleaned, allowing for multiple uses and prolonged service life. This reduces downtime and contributes to cost-effectiveness, making it an ideal choice for businesses seeking reliable filtration solutions.5. Customization Options: (company name) provides a wide range of customization options, such as pore size, shape, thickness, and dimensions, to meet the specific requirements of each industry and client. This flexible approach ensures optimized performance and compatibility with existing systems.Applications and Benefits:The Sintered Stainless Steel Filter offers numerous benefits, making it a game-changer in the field of filtration technology. Some of the key advantages include:1. Enhanced Product Quality: By ensuring the removal of impurities and contaminants, this filter guarantees superior product quality, meeting the stringent standards of industries such as pharmaceuticals and food processing.2. Improved Process Efficiency: With its exceptional particle retention capabilities, it minimizes product loss, improving overall process efficiency and reducing operating costs. This is particularly vital in industries dealing with expensive raw materials or high-value products.3. Environmental Stewardship: The Sintered Stainless Steel Filter aligns with sustainable practices, contributing to environmental stewardship. Its reusable nature reduces waste generation and helps organizations achieve their eco-conscious goals.Conclusion:In a world where filtration plays a pivotal role, (company name) has introduced an innovative filtration solution that raises the bar for efficiency, durability, and customization. The Sintered Stainless Steel Filter brings numerous advantages across various industries, ensuring enhanced product quality, improved process efficiency, and environmental sustainability. With its cutting-edge technology and commitment to customer satisfaction, (company name) has positioned itself as a frontrunner in the rapidly evolving filtration industry.

Spot Welded Screen Packs: Innovations in Screen Manufacturing

Spot Welded Screen Packs: Enhancing Efficiency and Quality in FiltrationIn today's fast-paced world, industries across various sectors rely heavily on efficient filtration systems to ensure optimum productivity and quality in their operations. One innovative solution that has gained significant attention and praise is the spot welded screen pack. Designed to enhance filtration performance, these screen packs have become an indispensable tool in many industries, contributing to enhanced efficiency and improved end products.{Company Introduction}Screen packs play a crucial role in filtration processes, acting as a barrier between the raw material and the desired end product. They consist of a series of wires that are woven or welded together to form a mesh structure. The size and configuration of the mesh can be tailored to meet specific filtration requirements, allowing for the separation of unwanted particles or impurities while allowing desired substances to pass through.Traditional screen packs often face challenges such as clogging and reduced efficiency over time, leading to frequent replacement and increased downtime. However, spot welded screen packs provide a highly effective solution, offering improved durability and longevity. By employing a spot welding technique, these screen packs eliminate the risk of unraveling or fraying, ensuring a more robust and long-lasting filtration system.One of the key advantages of spot welded screen packs is their enhanced structural integrity. The spot welding process involves joining the wires at specific points, creating a secure bond that prevents any movement or separation. This results in a seamless screen pack that can withstand higher levels of pressure and tension without compromising filtration efficiency. As a result, industries can significantly reduce maintenance costs and enhance overall operational performance.Moreover, the spot welding technique allows for greater customization and flexibility in the design of screen packs. Manufacturers can easily modify the mesh size, wire diameter, and open area percentage to suit the specific needs of each application. This adaptability ensures that the screen pack is precisely tailored to provide optimal filtration performance, eliminating any concerns of over-filtration or under-filtration.Spot welded screen packs are widely used in industries such as plastics extrusion, polymer processing, chemical manufacturing, food processing, and pharmaceuticals, among others. In plastics extrusion, for instance, these screen packs are employed in the melt filtration process to remove contaminants and impurities from the melted plastic before it is shaped into the desired form. The use of spot welded screen packs in this application ensures a cleaner and more consistent end product, minimizing defects and improving the overall quality.The pharmaceutical industry greatly benefits from spot welded screen packs as well. In the production of various medicines and drugs, it is vital to maintain strict quality control and ensure that no unwanted particles enter the final product. Spot welded screen packs offer an effective means of achieving this, providing a reliable filtration solution that meets high regulatory standards.As industries continue to push the boundaries of innovation and demand greater efficiency, the spot welded screen pack technology is expected to witness further advancements. Manufacturers are continually exploring new materials and innovative manufacturing processes to enhance the performance and durability of these screen packs. This will undoubtedly lead to improved filtration efficiency, reduced maintenance costs, and increased productivity, benefiting a wide range of industries.In conclusion, spot welded screen packs have revolutionized the filtration industry by offering enhanced durability, customization options, and improved filtration performance. Their unique design and manufacturing techniques have made them a highly sought-after solution for various industrial applications. As technology continues to evolve, spot welded screen packs are poised to play an even more significant role in safeguarding operational productivity and ensuring the delivery of high-quality end products.

Top-Rated Sintered Wire Mesh Filter: A Comprehensive Overview

Sintered Wire Mesh Filter: The Future of Filtration TechnologyIn today's fast-paced world, technological innovations constantly emerge to meet the ever-growing demands of various industries. One such innovation is the Sintered Wire Mesh Filter, which has revolutionized the filtration technology landscape. This advanced filter, developed by [Company], offers unmatched efficiency, versatility, and durability, making it the go-to solution for a wide range of applications.[Company] is a trusted name in the industry, known for its commitment to quality, innovation, and customer satisfaction. With decades of experience and a team of highly skilled engineers and technicians, [Company] has established itself as a leader in the development and manufacturing of advanced filtration solutions. The company's state-of-the-art facilities and stringent quality control measures ensure that every product meets the highest standards and delivers exceptional performance.The Sintered Wire Mesh Filter is a testament to [Company]'s dedication to innovation and excellence. This filter is constructed using multiple layers of woven wire mesh, which are sintered together to create a strong, durable, and uniform structure. The sintering process ensures that the mesh layers are tightly bonded, eliminating the risk of delamination and ensuring consistent filtration performance.One of the key advantages of the Sintered Wire Mesh Filter is its ability to provide precise and reliable filtration. The uniform pore size distribution and high particle retention efficiency make it an ideal choice for critical applications where consistent performance is essential. Whether it's separating solids from liquids, removing contaminants from gases, or protecting sensitive equipment from harmful particles, this filter delivers exceptional results.Furthermore, the Sintered Wire Mesh Filter offers excellent flow rates and minimal pressure drop, ensuring efficient operation and energy savings. Its robust construction and resistance to corrosion, chemicals, and high temperatures make it suitable for demanding industrial environments. Additionally, the filter can be easily cleaned and reused, reducing maintenance costs and environmental impact.The versatility of the Sintered Wire Mesh Filter is another standout feature. With the ability to customize the filter's pore size, thickness, and dimensions, [Company] can tailor the filter to meet specific application requirements. Whether it's in the pharmaceutical, food and beverage, petrochemical, automotive, or aerospace industry, this filter can be adapted to suit diverse needs.Moreover, [Company] provides comprehensive technical support and consultation to help customers select the right filter for their unique needs. The company's dedication to customer satisfaction means that clients receive expert guidance and reliable solutions that enhance their processes and products.As industries continue to evolve and demand more advanced filtration solutions, the Sintered Wire Mesh Filter from [Company] stands out as a game-changer. Its unparalleled performance, durability, and flexibility make it a key component in ensuring the quality and efficiency of various processes.In conclusion, [Company] has once again demonstrated its commitment to innovation and excellence with the development of the Sintered Wire Mesh Filter. This groundbreaking technology is set to redefine the standards of filtration and contribute to the advancement of various industries. With [Company]'s expertise and dedication to customer satisfaction, the future of filtration technology looks brighter than ever.

Durable and Versatile Expanded Metal Mesh Panels for Various Applications

The use of expanded metal mesh panels has been growing rapidly in various industries and applications. Expanded metal mesh panels are widely used in construction, architecture, industrial, and residential sectors due to their versatility, durability, and aesthetic appeal.These panels are manufactured by expanding a metal sheet in a single operation, creating diamond-shaped openings in the sheet. This unique manufacturing process results in a product that is stronger and lighter than the original sheet. Expanded metal mesh panels are also known for their excellent ventilation, light transmission, and ability to provide security and privacy.One of the leading manufacturers and suppliers of expanded metal mesh panels is {}. Established in {}, {} has been at the forefront of producing high-quality expanded metal mesh panels for a wide range of applications. With a strong commitment to innovation and customer satisfaction, {} has continuously expanded its product line and production capabilities over the years.The company's expanded metal mesh panels are available in a variety of materials, including stainless steel, aluminum, carbon steel, and galvanized steel. This allows {} to cater to the diverse needs of its customers and provide solutions for different environmental and performance requirements.In addition to standard panels, {} also offers custom-made expanded metal mesh panels, tailored to specific dimensions, shapes, and patterns. This level of customization enables the company to serve a wide range of industries, such as architectural design, interior decoration, filtration, security, and machine guarding.One of the key advantages of {}'s expanded metal mesh panels is their high strength-to-weight ratio, which makes them ideal for structural and load-bearing applications. The panels can be easily formed, cut, and fabricated to suit specific project requirements, making them a popular choice for architects, designers, and engineers.Moreover, {}'s expanded metal mesh panels are designed to provide effective ventilation and airflow in various settings, including buildings, machinery, and outdoor structures. This feature is particularly important in industrial and commercial environments, where proper air circulation is essential for safety and productivity.With a strong focus on quality and performance, {} ensures that its expanded metal mesh panels meet industry standards and specifications. The panels are manufactured using advanced equipment and processes, and undergo rigorous testing to ensure their reliability and durability in demanding conditions.{}'s commitment to sustainability is also reflected in its production processes, where efforts are made to minimize waste, energy consumption, and environmental impact. This sustainable approach has earned {} recognition and accreditation from industry bodies and organizations.In conclusion, the increasing demand for expanded metal mesh panels across various industries has fueled the growth and innovation of companies like {}. With a wide range of products, custom solutions, and a strong emphasis on quality and sustainability, {} continues to lead the way in providing reliable and versatile expanded metal mesh panels for its customers. As the use of expanded metal mesh panels continues to expand, {} remains at the forefront of the industry, providing innovative solutions that meet the evolving needs of its customers.

Durable and Flexible Mesh Screen for Plastic Materials

Introducing the Latest Innovation in Plastic Mesh Screen TechnologyIn the world of manufacturing and industrial production, finding the right materials and tools to create high-quality products is essential. One such crucial tool in the plastic industry is the mesh screen, which plays a vital role in various processes such as sorting, filtering, and sieving. This is why the introduction of the latest innovation in plastic mesh screen technology by (need remove brand name) has grabbed the attention of professionals and industry experts.(need remove brand name) is a renowned leader in the field of plastic manufacturing, known for its commitment to innovation, quality, and customer satisfaction. With a strong focus on research and development, the company has consistently pushed the boundaries of what is possible in the industry, and their latest product is no exception.The new plastic mesh screen by (need remove brand name) is a game-changer in the industry, boasting several key features that set it apart from traditional mesh screens. Made from high-quality, durable materials, the mesh screen is designed to withstand the rigors of industrial use, ensuring longevity and reliability. Its unique composition also makes it resistant to corrosion, abrasion, and extreme temperatures, making it suitable for a wide range of applications.One of the most significant advantages of the new plastic mesh screen is its superior filtering capabilities. The precision-engineered mesh design ensures efficient sieving and sorting, allowing for the separation of particles of varying sizes with unmatched accuracy. This feature is particularly valuable in industries such as food processing, pharmaceuticals, and mining, where the purity and quality of the end product are of utmost importance.In addition to its filtering capabilities, the new plastic mesh screen also offers enhanced flexibility and versatility. Its modular design allows for easy customization to fit specific requirements, making it suitable for a wide range of industrial applications. Whether it's used for separating different materials, protecting machinery from debris, or creating barriers for safety purposes, the mesh screen by (need remove brand name) offers a solution that is both effective and adaptable.Furthermore, the innovative design of the mesh screen also ensures improved airflow and ventilation, making it ideal for applications where consistent air circulation is necessary. This feature is particularly valuable in industries such as agriculture, construction, and HVAC, where maintaining optimal airflow is critical for the success of various processes.Another key highlight of the new plastic mesh screen is its environmental sustainability. Made from recyclable materials and designed to minimize waste, the mesh screen reflects (need remove brand name)'s commitment to reducing its environmental footprint and promoting eco-friendly practices in the industry. As the demand for sustainable solutions continues to grow, the company's emphasis on environmental responsibility is not only commendable but also aligns with the broader industry trends.In conclusion, the introduction of the new plastic mesh screen by (need remove brand name) marks a significant milestone in the industry, representing a leap forward in terms of innovation, performance, and sustainability. With its superior filtering capabilities, flexibility, and environmental consciousness, the mesh screen is poised to become a go-to solution for a wide range of industrial applications. As (need remove brand name) continues to lead the way in plastic manufacturing, their latest innovation reaffirms their position as a pioneer in the industry and sets a new standard for excellence.

Durable and Versatile Plastic Filter Mesh for Various Applications

Plastic Filter Mesh: A Revolutionary Solution for Filtration NeedsIn recent years, the demand for effective filtration solutions has been on the rise. The need for clean and clear water, air, and other fluids has become a top priority for industries and individuals alike. With the increasing concern for environmental pollution and air quality, there has been a growing demand for innovative and efficient filtration products.One company that has been at the forefront of providing cutting-edge filtration solutions is {}. With its extensive expertise in plastic extrusion and advanced engineering capabilities, {} has been able to develop a range of high-quality plastic filter mesh products that are revolutionizing the way filtration needs are met.{} was founded in the early 2000s, with a vision to become a leading supplier of plastic extrusion products. Over the years, the company has made significant strides in the development and manufacturing of a wide range of plastic products, including filter mesh, tubing, netting, and more. Through its commitment to innovation, quality, and customer satisfaction, {} has established itself as a trusted and reliable partner for customers across various industries.The company's plastic filter mesh products have gained widespread recognition for their exceptional performance and durability. With a focus on precision engineering and quality materials, {} has been able to develop filter mesh products that offer superior filtration capabilities, long-lasting durability, and easy maintenance. These products have been used in a wide range of applications, including water filtration, air purification, industrial fluid processing, and more.One of the key features of {}'s plastic filter mesh products is their high level of customization. The company's advanced manufacturing capabilities allow for the production of filter mesh in various sizes, shapes, and configurations, to meet the specific needs of different industries and applications. This level of customization has been crucial in helping customers achieve optimal filtration results and improve overall operational efficiency.Furthermore, {}'s plastic filter mesh products are designed to be environmentally friendly and sustainable. With a keen awareness of the growing concerns around plastic waste, the company has implemented various initiatives to minimize its environmental impact. This includes the use of recycled materials in the production of filter mesh, as well as the development of products that are designed for long-term use and easy recyclability.In addition to its commitment to product quality and environmental sustainability, {} has also prioritized customer satisfaction and support. The company maintains a dedicated team of experts who work closely with customers to understand their specific filtration needs and provide tailored solutions. From product selection and customization to technical assistance and after-sales support, {} has earned a reputation for delivering exceptional customer service.Overall, {}'s plastic filter mesh products have been a game-changer in the filtration industry. With their superior performance, customization options, and environmental sustainability, these products have helped countless customers improve their filtration processes and achieve better results. As the demand for quality filtration solutions continues to grow, {} is well-positioned to lead the way with its innovative and reliable products.

How a Mesh Screen Can Help Improve the Quality of Plastic Products

Title: Revolutionary Mesh Screen Innovation Eases Plastic Waste ManagementIntroduction:In today's world, plastic waste has become one of the most pressing environmental issues, and finding innovative solutions to address this problem is paramount. This is where a ground-breaking company, whose name we cannot disclose due to legal constraints, has stepped in with their innovative Mesh Screen for Plastic. With their expertise and dedication towards creating sustainable materials, this invention has the potential to revolutionize the way we manage and recycle plastic waste.Body:1. The Plastic Waste Crisis: - Begin by highlighting the severity of the plastic waste crisis, such as the alarming volume of plastic waste generated annually globally. - Discuss the devastating consequences of plastic waste on marine life and ecosystems, as well as its indirect impact on human health. - Emphasize the urgent need for innovative solutions to tackle this crisis effectively.2. Introduction to the Mesh Screen for Plastic: - Provide a brief overview of the Mesh Screen for Plastic, emphasizing its effectiveness in waste management and recycling processes. - Explain that this invention is designed to separate different types of plastic waste, making it easier to recycle efficiently. - Outline the unique features and benefits of the Mesh Screen, such as its durability, affordability, and ease of use.3. How the Mesh Screen Works: - Describe the operational mechanism of the Mesh Screen, providing a step-by-step explanation of its functionality. - Explain how the screen is capable of separating plastics of varying sizes, ensuring efficient and accurate sorting. - Highlight any additional functionalities or applications of the Mesh Screen, such as its potential for integration into existing recycling systems.4. Positive Environmental Impacts: - Discuss the potential environmental benefits of using the Mesh Screen, particularly by reducing the amount of plastic waste sent to landfills and incinerators. - Emphasize how this innovative solution contributes to the circular economy concept, promoting the reuse and recycling of plastic materials. - Cite examples of other successful waste management solutions around the world and their positive impact on local environments.5. Economic Advantages and Market Potential: - Highlight the economic advantages associated with adopting the Mesh Screen, such as the potential for job creation and cost reductions in waste management processes. - Discuss the market potential of the Mesh Screen, including its attractiveness to waste management companies and recycling facilities. - Mention any ongoing collaborations or partnerships that the company has established to further develop and market the Mesh Screen.6. Future Development and Expansion Plans: - Provide insights into the company's future plans for the Mesh Screen, including research and development efforts aimed at improving its efficiency and scalability. - Discuss potential expansion strategies, both domestically and internationally, to reach a wider audience and maximize the impact of this innovative solution. - Mention any regulatory and policy changes that may aid the widespread adoption of the Mesh Screen within the plastic waste management industry.Conclusion:In conclusion, the undisclosed company's Mesh Screen for Plastic offers a glimmer of hope in combating the plastic waste crisis. With its unparalleled sorting capabilities and potential for easy integration into existing recycling processes, this innovation has the power to transform the way we manage plastic waste. As the global community collectively aims to reduce plastic pollution, the Mesh Screen serves as a shining example of the revolutionary solutions needed to create a sustainable and greener future.